Soil real-time monitoring system based on intelligent agricultural planting

A real-time monitoring system and agricultural technology, applied in the direction of measuring devices, engine frames, measuring instrument components, etc., can solve the problems of inconvenient control box installation and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

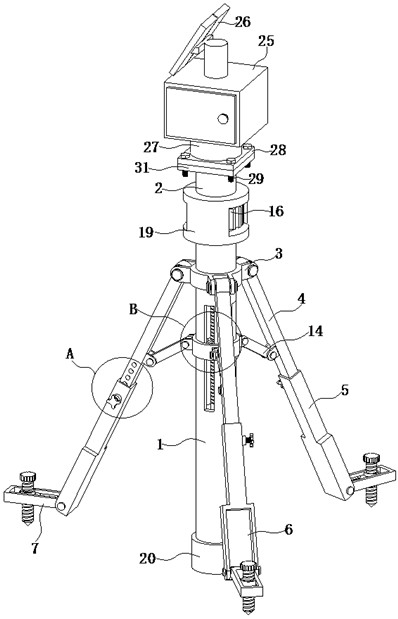

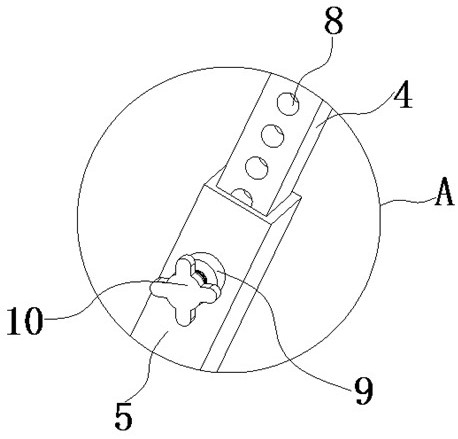

[0037] see Figure 1-9, the present invention provides a technical solution: a real-time soil monitoring system based on intelligent agricultural planting, including a lower pillar 1, an upper pillar 2 and a control box 25, and the outside of the top of the lower pillar 1 is fixedly installed with a mounting plate 3, and the mounting plate 3 There is a first adjusting rod 4 hinged inside, the bottom of the first adjusting rod 4 is sleeved with a second adjusting rod 5, the bottom of the second adjusting rod 5 is fixedly installed with a positioning device 7, and the inside of the lower pillar 1 is sleeved with an adjusting screw 11. The limit slider 12 is sleeved on the outside of the adjustment screw 11, and the side of the limit slider 12 away from the adjustment screw 11 is fixedly installed with a movable disc 13, and the outside of the movable disc 13 is hinged with a transmission rod 14, which is far away from the movable One side of the disk 13 is hingedly connected wit...

Embodiment 2

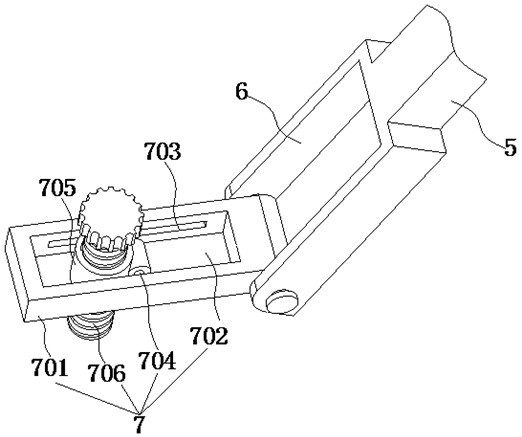

[0040] Such as Figure 1-9 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the positioning device 7 includes a movable frame 701, and the inside of the movable frame 701 is provided with a groove 702, and both sides of the inner wall of the groove 702 are provided with slide grooves 703 , a rotating shaft 704 is movably installed inside the chute 703 , the outer portion of the rotating shaft 704 is sleeved with a connecting sleeve 705 , and the inner portion of the connecting sleeve 705 is sleeved with a fixed pile 706 .

[0041] In this embodiment, the bottom of the fixed pile 706 is a sharp point, which is conducive to drilling the fixed pile 706 into the ground, which has a labor-saving effect and prevents the operator from spending a lot of effort. When fixing the device, the connecting sleeve 705 must be rotated , align the tip of the bottom of the fixed pile 706 with the ground, and pull the fixed pile 706 along the chute 703,...

Embodiment 3

[0043] Such as Figure 1-9 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a placement groove 6 is opened on the side of the second adjustment rod 5 away from the lower pillar 1, and the positioning device 7 is located inside the placement groove 6 .

[0044] In this embodiment, by setting the placement groove 6, when the device is not in use, the entire positioning device 7 can be received into the placement groove 6, avoiding accidental injury to the operator by the tip of the fixing pile 706 in the positioning device 7, and at the same time The whole positioning device 7 is accommodated, which is convenient for the operator to move.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com