Biomass combustion furnace

A biomass combustion furnace and burner technology, applied in the direction of combustion methods, combustion equipment, solid fuel combustion, etc., can solve the problems of air pollution, affecting indoor air quality, flying, etc., and achieve air intake efficiency guarantee and ash fall effect Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

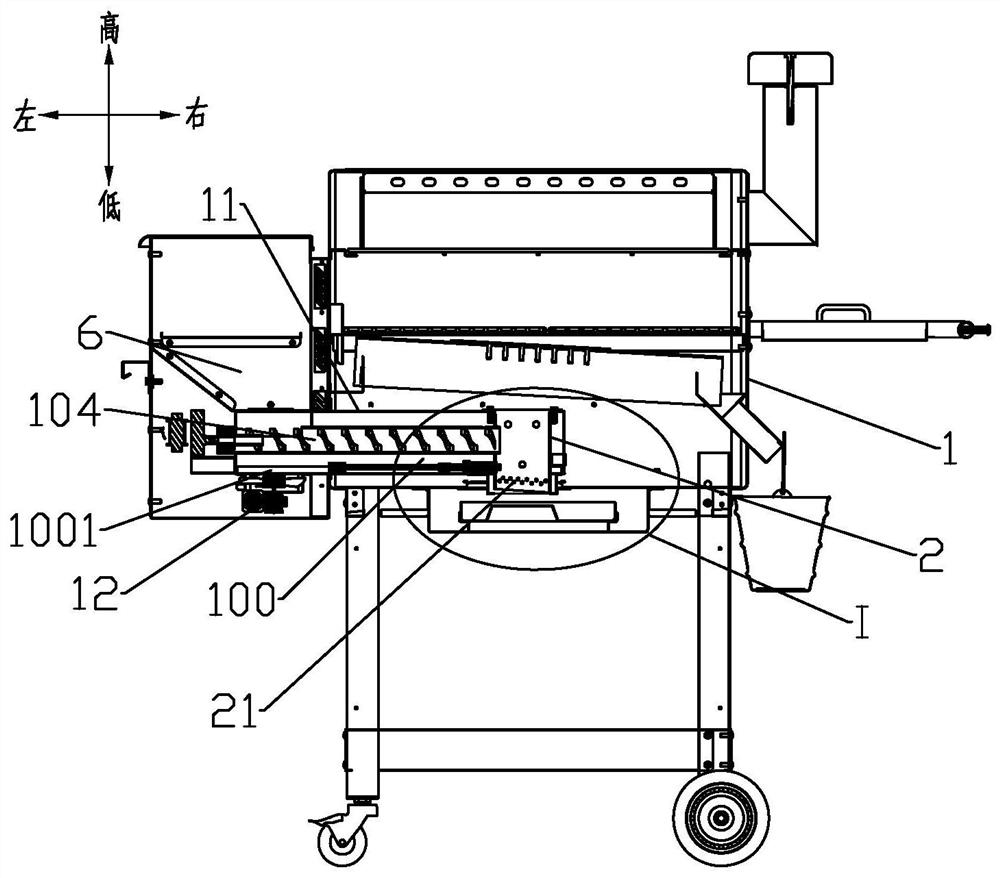

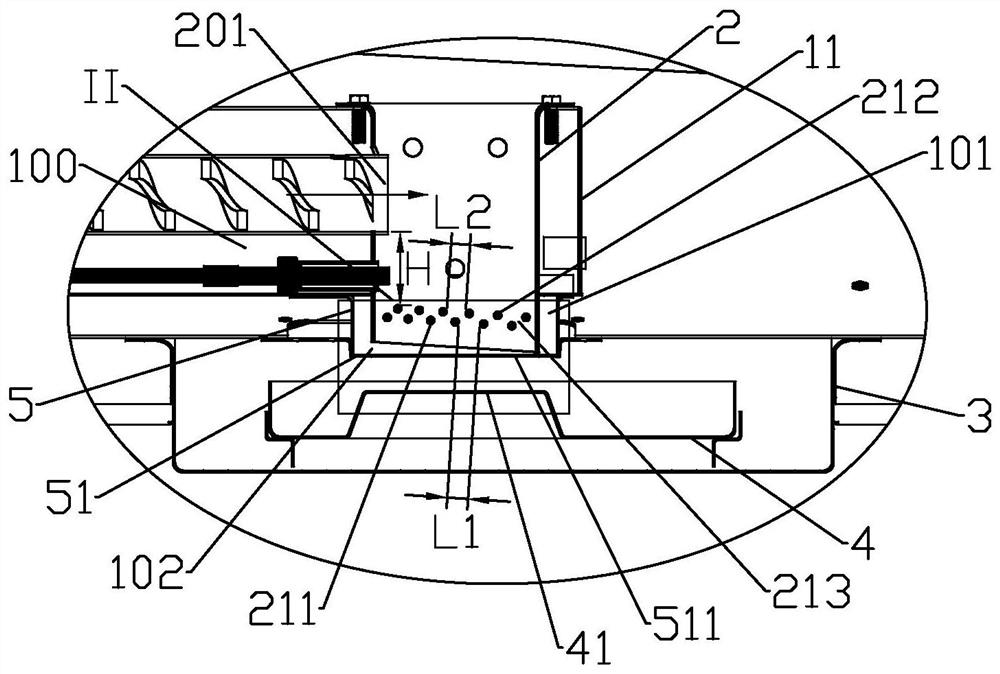

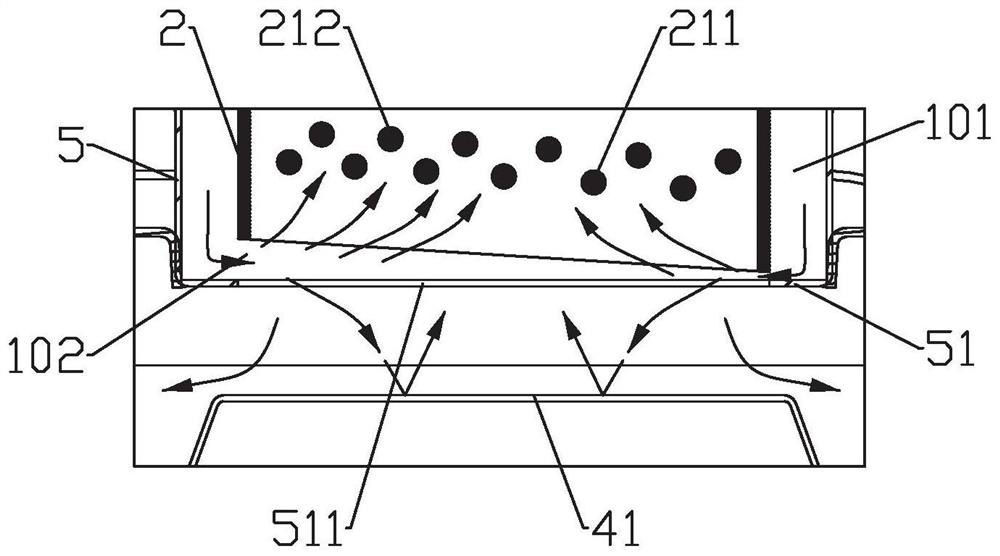

[0030] Such as Figure 1 to Figure 6 As shown, this embodiment provides a biomass combustion furnace, which includes a furnace body 1, a fuel hopper 6 is provided outside the furnace body 1, a burner 2 is provided inside the furnace body 1, and a feed port is provided on the side wall of the burner 2 201, the feed port 201 is connected to the bottom of the fuel hopper 6 through the feeding channel 104, the top of the burner 2 is open, the furnace body 1 is provided with an air intake channel extending to the bottom of the burner 2, and the bottom surface of the burner 2 is provided with a There is a grate 21 above the through opening for air intake and ash falling. The bottom of the furnace body 1 is provided with a water storage tray 3 and an ash receiving tray 4. The ash receiving tray 4 is located below the burner 2 and faces the through opening. mouth.

[0031] In this embodiment, a large area of ash falling and air intake is realized through the through opening, so tha...

Embodiment 2

[0044] Such as Figure 7 to Figure 11 As shown, an auxiliary support body 214 for maintaining the primer is provided under the first layer of support body 211, the auxiliary support body is higher than the through opening, and the auxiliary support body 214 is located on the side below the feed port 201 and the range of setting does not exceed the grate 1 / 2 of the covered area, 1 / 2 here is just an approximate number, so as not to affect the normal dust fall and air intake. Adding the auxiliary support body 214 has two functions. On the one hand, in the state of high fire, it can reduce the ash falling efficiency and the air intake below the feed port 201, and the combustion efficiency of the pellet fuel at this position can be effectively controlled, so as to effectively avoid backfire. The occurrence of a fire situation, on the other hand, is to maintain the primer in a small fire state to avoid extinguishing. In this embodiment, the auxiliary support body 214 adopts a rod s...

Embodiment 3

[0051] In addition to setting two layers of support, you can also increase the number of layers on this basis, such as Figure 12 As shown, the grate also includes a third layer of support 215 fixed to the burner 2, the third layer of support 215 is higher than the second layer of support 212, between the third layer of support 215 and the second layer of support 212 There is a second channel 216, the width W2 of the second channel 216 is smaller than D, and the distance L3 between two adjacent third-layer supports 215 is larger than D and smaller than 2D. It can be understood that, according to actual needs, the number of layers of the support body can be increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com