High-precision surface type measuring system

A measurement system and high-precision technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve problems such as difficult to achieve nano-scale surface accuracy measurement, achieve good tracking effect, reduce errors, and stabilize the rotation of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

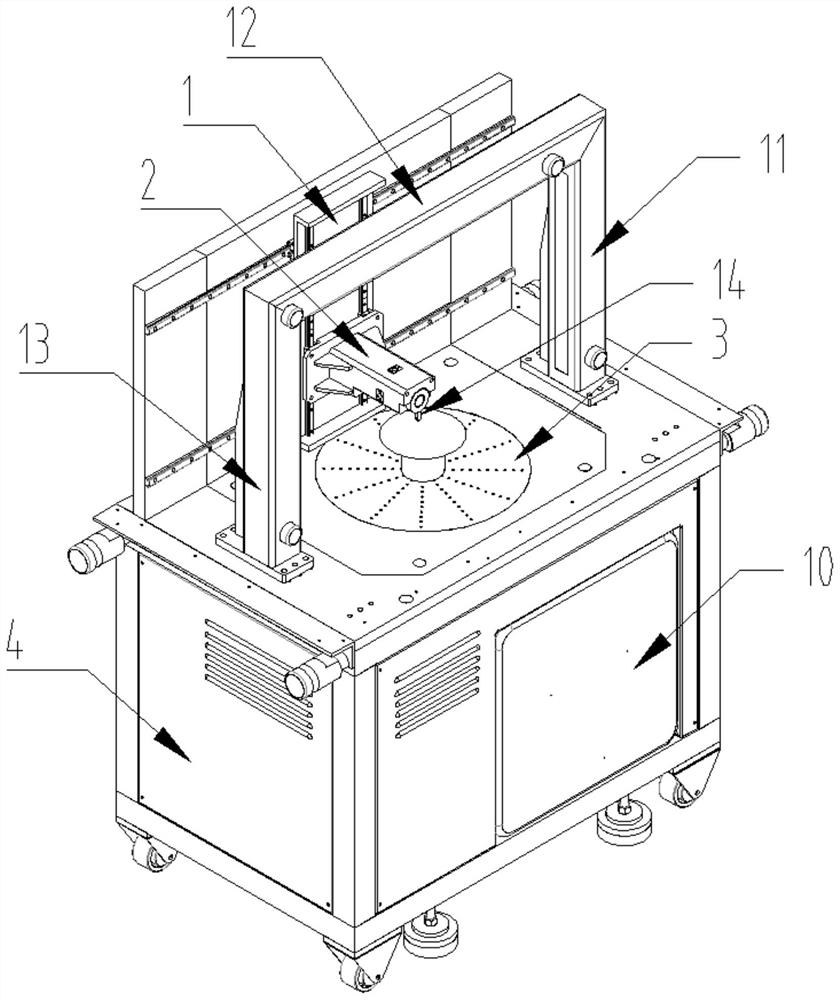

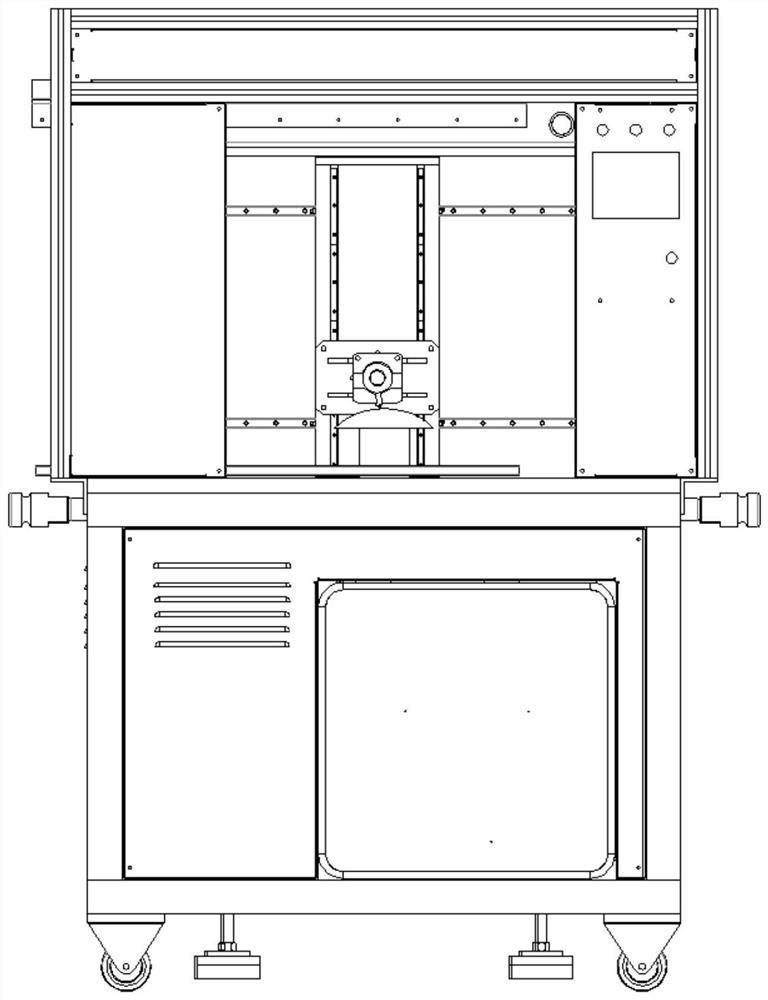

[0035] A high-precision surface measurement system, such as figure 1 As shown, it includes the real-time feedback system, motion scanning system 1, real-time positioning laser system 2, rotary table 3 and support frame 4, and the rotary table 3, real-time feedback system and motion scanning system 1 are all installed on the support frame 4. The positioning laser system 2 is installed on the motion scanning system 1. The real-time positioning laser system 2 includes a rotation axis 7 on which a spectral confocal measuring head 14 is installed. The motion scanning system 1 includes an X-direction motion pair 5, and an X-direction motion pair 5 is equipped with a Z-direction motion pair 6, and the rotating shaft 7 is installed on the Z-direction motion pair 6 through a mounting bracket, and a laser displacement sensor is installed on the mounting bracket.

[0036] Such as Figure 5 As shown, in order to realize the normal tracking of the spectral confocal probe 14 along the surf...

Embodiment 2

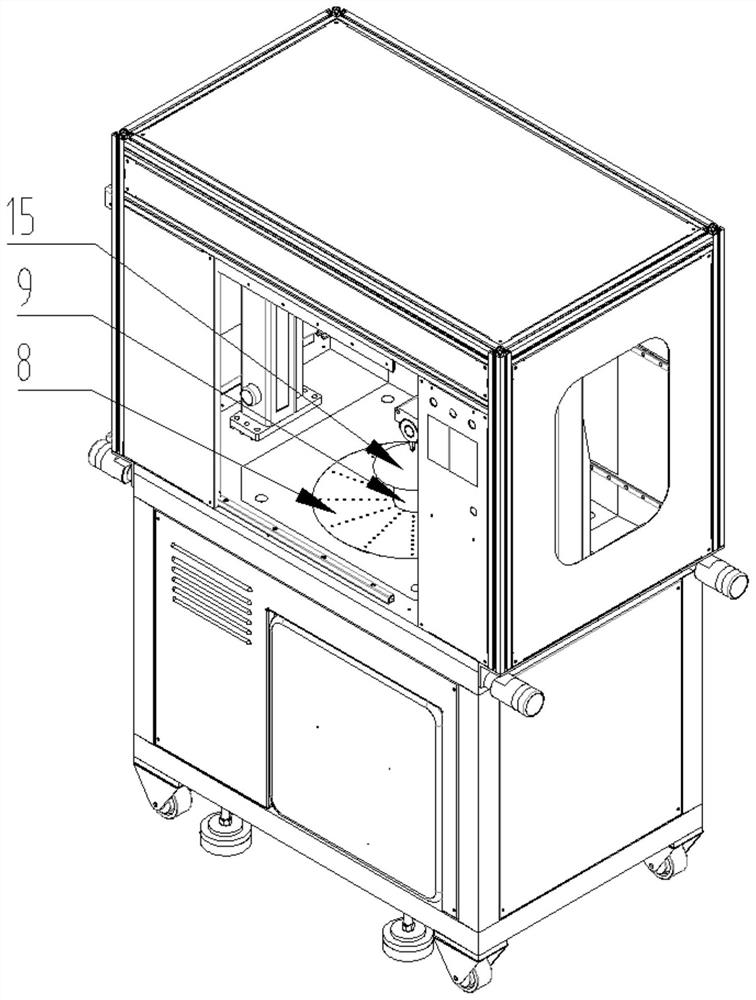

[0039] On the basis of Example 1, such as figure 2 As shown, the rotary table 3 includes a rotary mechanism 8 installed on the support frame 4, and the workpiece fixing seat 9 is installed on the rotary mechanism 8. Both the rotary mechanism 8 and the motion scanning system 1 are connected with a motion host 10, and the motion host 10 is installed on the Support frame 4 inside.

[0040] Preferably, an air flotation system is provided under the slewing mechanism 8 . The air flotation system can establish a fixed range of air conditions around the workpiece 15 to be measured, which reduces the influence of temperature, humidity, and wind speed on the measurement structure during the measurement process of the entire system, and prevents large errors due to differences in air conditions.

Embodiment 3

[0042] On the basis of Example 1, such as Figure 3-4As shown, the real-time feedback system includes a positioning reference frame 11 and a plurality of plane mirrors. The positioning reference frame 11 is installed above the rotary table 3, and the plane mirrors are all installed on the positioning reference frame 11. 12 and Z direction reflector 13 to form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com