Computer host intelligent bracket machining device

A processing device and computer technology, applied in the computer field, can solve problems such as the inability to test the intelligent bracket of the computer host

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

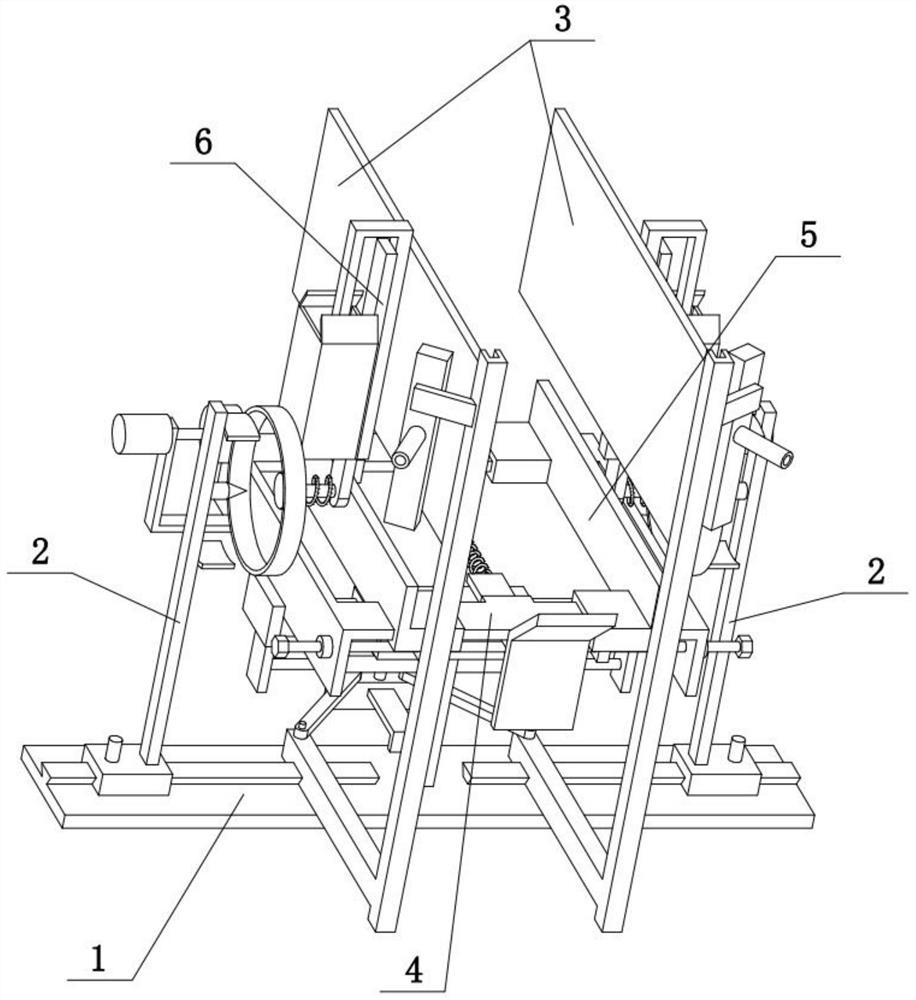

[0031] Combine below Figure 1-11 Describe this embodiment mode, the present invention relates to the field of computers, more specifically a computer mainframe intelligent bracket processing device, including frosted glass plate 3, air spray head 301, vertical rod 303, connecting piece 304 and joint 305. The present invention can be used for Computer host Smart Bay for testing.

[0032] The front part of the frosted glass plate 3 is fixedly connected to the top of the vertical bar 303, and the top of the vertical bar 303 is fixedly connected with the air spray head 301 through the connecting piece 304. The front side of the air spray head 301 is provided with a joint 305, and the rear of the air spray head 301 The side is provided with fine spray holes, and the fine spray holes face the frosted glass plate 3 . When the rocking bar 6 swings, it can drive the sliver 601 to swing. The sliver 601 is immersed in water, and the sliver 601 wipes the water on the frosted glass plate...

specific Embodiment approach 2

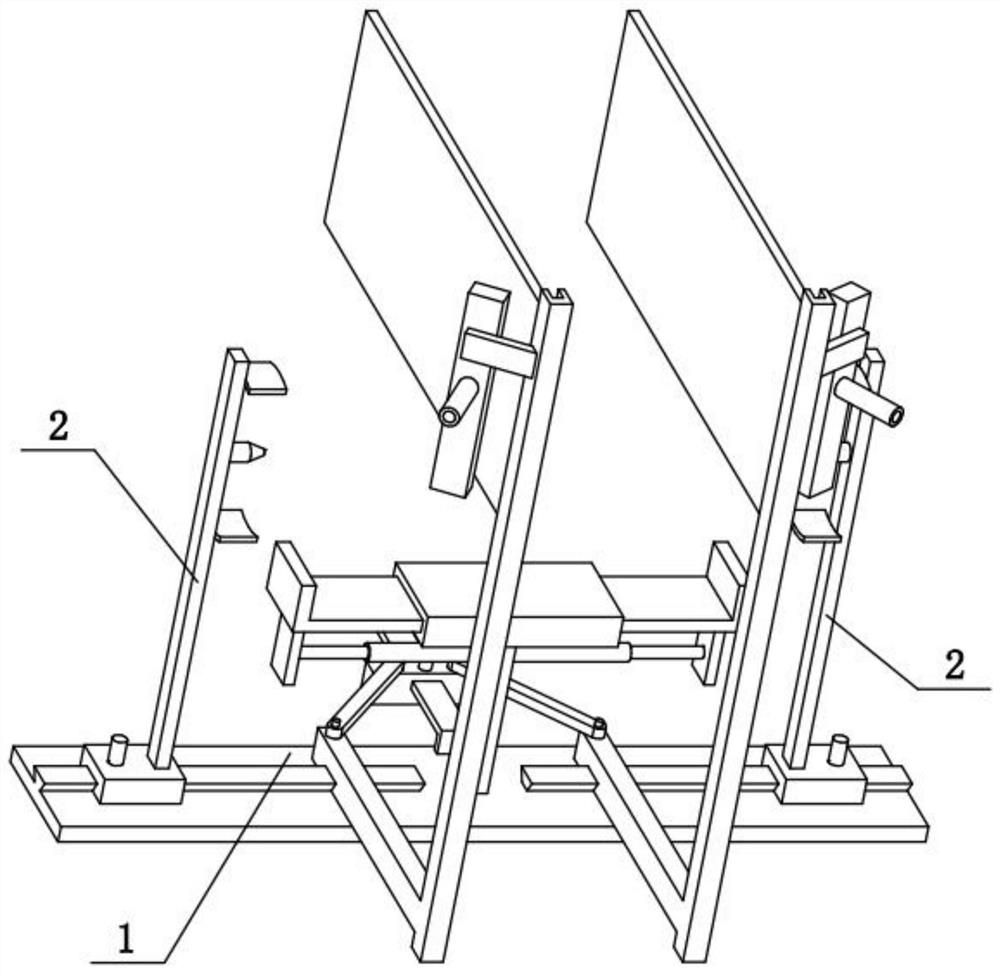

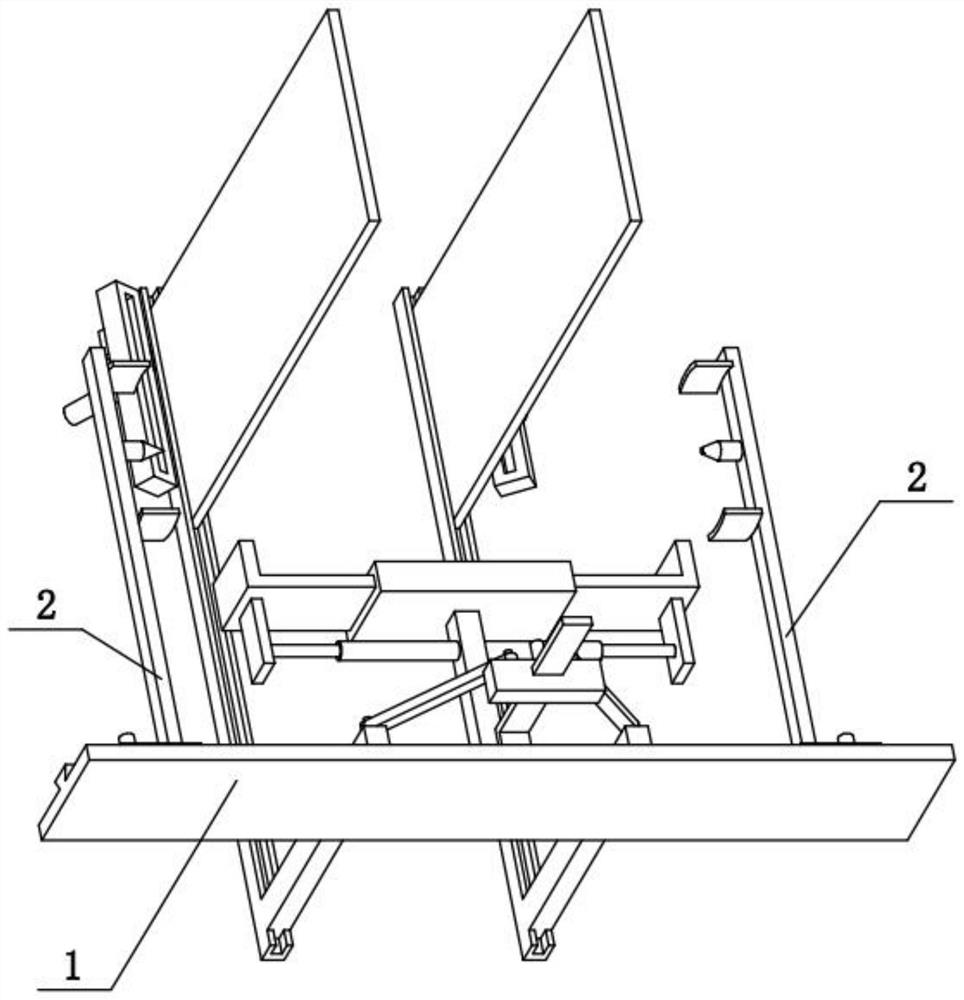

[0034] Combine below Figure 1-11 To illustrate this embodiment, the host computer intelligent bracket processing device also includes a bottom plate 1, a slide rail 101, a hollow seat 102, a drawing plate 103, a clamping edge 104, an oil cylinder 105, a column 106 and a bottom bar 302, and the left and right sides of the bottom plate 1 Both parts are provided with slide rails 101, one vertical bar 303 is provided on the left and right sides, and the lower parts of the two vertical bars 303 are fixedly connected with bottom bars 302, and the two bottom bars 302 are slidably connected to the two slide rails 101 respectively. The middle part of the upper side of 1 is fixedly connected with a column 106, and the upper part of the column 106 is fixedly connected with a hollow seat 102, and the left and right sides of the hollow seat 102 are slidingly connected with a drawer plate 103, and the outer upper sides of the two drawer plates 103 are fixed Clamping ribs 104 are connected,...

specific Embodiment approach 3

[0036] Combine below Figure 1-11 To illustrate this embodiment, the computer host intelligent bracket processing device also includes a middle rod 107, a slider 108 and a hinged rod 109, the rear middle part of the bottom plate 1 is fixedly connected with the middle rod 107, and the middle rod 107 is slidably connected with a slider 108, the slider 108 is fixedly connected to the middle rod 107 by means of screw compression, two hinged rods 109 are hinged on the slider 108, and the other ends of the two hinged rods 109 are hinged on the two bottom rods 302 respectively. When the slider 108 moves back and forth on the middle rod 107, the two hinged rods 109 can drive the two bottom rods 302 to move left and right, and then drive the two frosted glass plates 3 to approach or move away from each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com