Vibration reduction design method for mechanical equipment

A technology of mechanical equipment and design methods, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as poor vibration reduction design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to illustrate the technical solution of the present invention more clearly, the following will briefly introduce the accompanying drawings used in the description of the embodiments. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

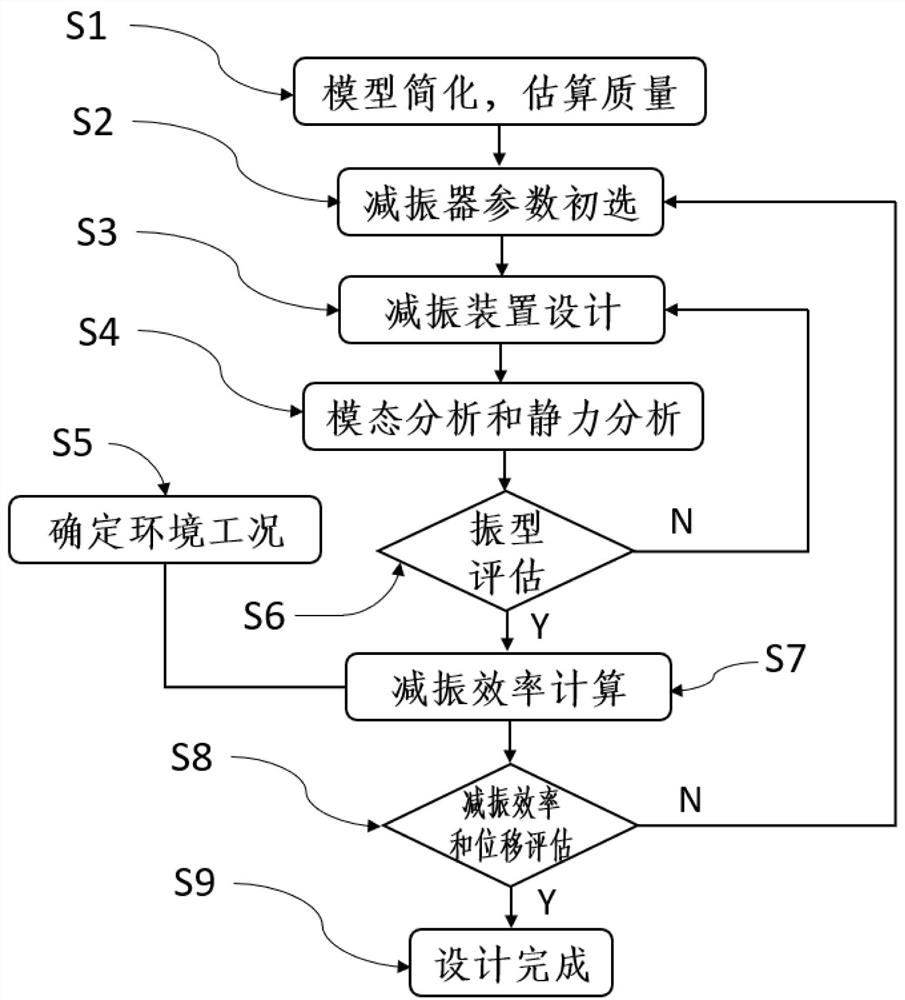

[0039] refer to figure 1 , figure 2 As shown, the invention discloses a vibration reduction design method of mechanical equipment, including the following steps.

[0040] Step S1, model simplification, simplifies the model of the mechanical equipment, and then estimates its total mass. The simplification of the model must maintain the same total mass as the original model and ensure that the mass distribution is basically consistent. Parts or subassemblies in the model can be replaced by blocks of equal mass.

[0041] Step S2, according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com