Intelligent counting device and account passing system

A point and intelligent technology, applied in image data processing, instruments, calculations, etc., can solve the problems of different thicknesses, inability to be widely applied, and different layers, so as to increase points, improve factory automation level, and reduce manpower cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

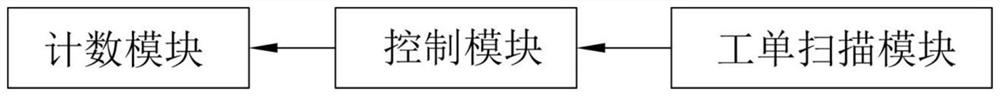

[0030] Example: Reference figure 1 The intelligent counting device and posting system shown include a work order scanning module for obtaining PCB board work order information, a counting module for identifying and counting PCB boards, a control module equipped with control and image processing algorithms, a work order scanning module, and a counting module. The modules are all connected with the control module. The work order scanning module can be any of the existing technologies, such as a two-dimensional code scanner and the like.

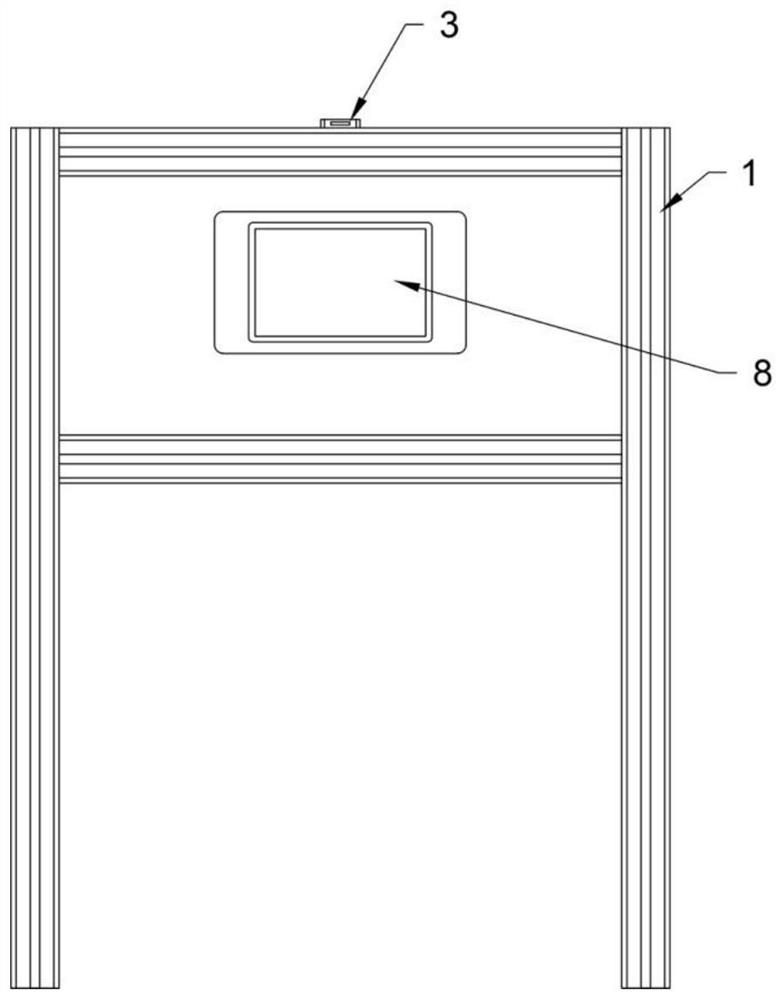

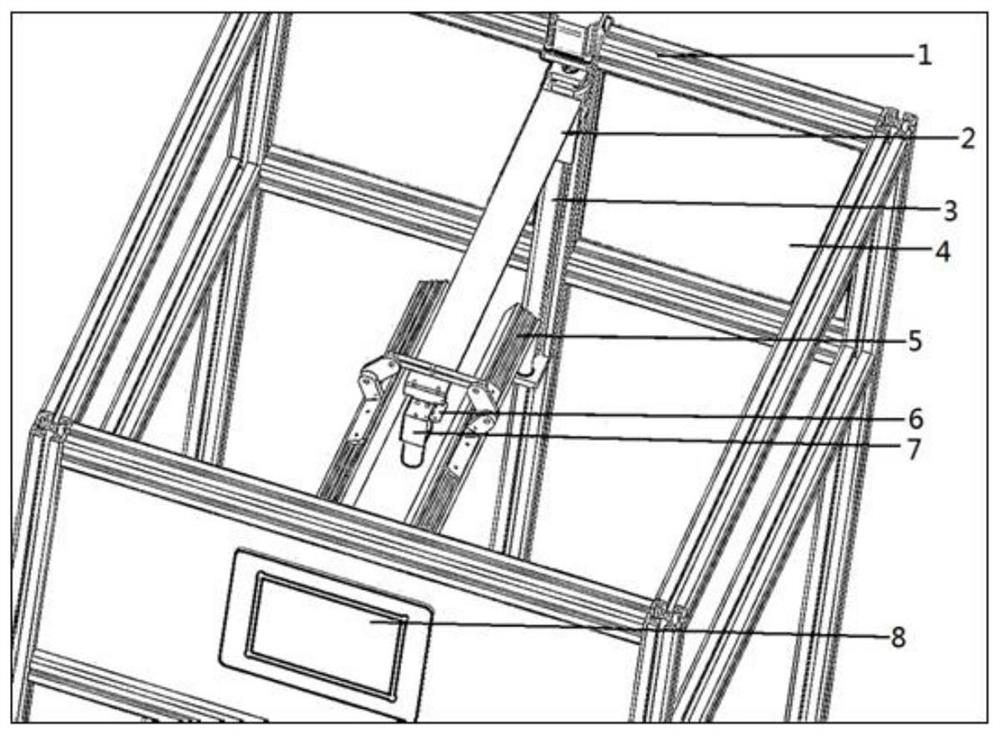

[0031] combine figure 2 , image 3 As shown, the counting module includes an outer frame 1, an adjustable transmission shaft 3 vertically installed on the inner wall of the outer frame 1, a drive bracket 2 installed on the adjustable transmission shaft 3, a CCD camera 7 installed on the bottom of the bracket 2, and a The distance sensor 6 at the bottom of the bracket 2, the variable light source 5 installed in the outer frame 2, the adjusta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com