Installation method of detachable building drum

An installation method and detachable technology, applied in the installation field of detachable drum building, can solve the problems of easy looseness, out-of-tune, musical instrument handling, increased transition costs, inconvenient handling, etc., so as to reduce the loss of transition, reduce The effect of loosening the drum body and reducing the force and extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

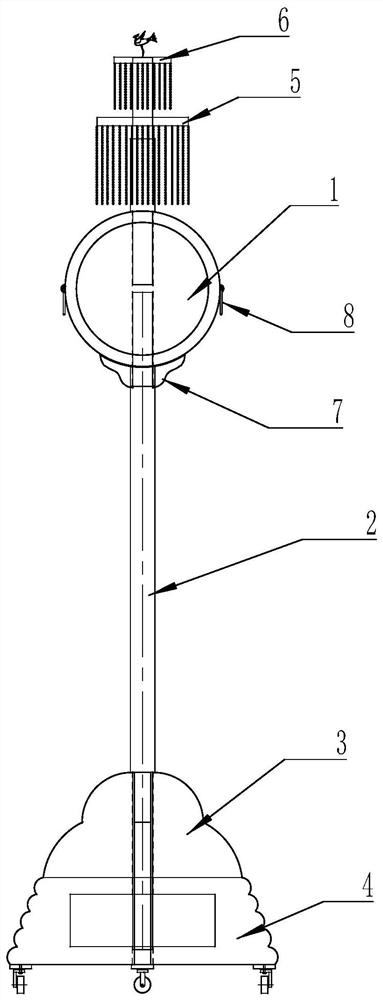

Embodiment 1

[0032] A pair of built-in drum rings 8 are arranged on both sides of the built-in drum 1. The built-in drum 1 is arranged horizontally. The center of the drum body of the built-in drum 1 is correspondingly reserved for a pair of perforations, and a drum core sleeve 12 is set in the paired perforation; 4. The supporting foot 3 is set on the base 4, and the building drum column 2 is set between the bottom of the building drum 1 and the supporting foot 3; Drum cherry plate 5; Drum cherry plate 5 and drum cap 6 are respectively set on the top of Jiangu 1, decorations are set in the center of the upper end of drum cap 6, cherry ears are evenly distributed on the lower edge of drum cherry plate 5 and drum cap 6, and drum cap 6 The upper end is provided with decorations, the lower end of the decorations is provided with an insertion rod, and the center of the upper end of the drum cap 6 is reserved for decoration sockets, and the insertion rods of decorations are arranged in the decor...

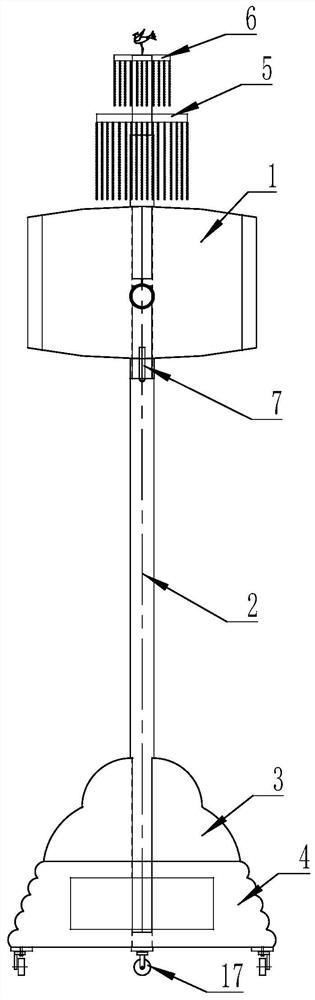

Embodiment 2

[0040] The drum core casing 12 of the built drum 1 is placed upwards, and the upper insertion column 11 is inserted into the drum core casing 12 by manually controlling the drum top column 9. When the boss of the drum top column 9 touches the drum core casing 12, it stops. Complete the installation of drum crown column 9;

[0041] After the drum top column 9 is installed on the upper end of the drum 1, the upper end of the cap column 10 is placed in the center reserved hole of the drum cherry plate 5 by manual control, and the lower part of the drum cherry plate 5 contacts the boss on the upper end of the drum top column 9 to stop. Complete the installation of the drum tray 5; after completing the installation of the drum tray 5, manually control the blind hole in the center of the drum cap 6 to be placed on the top of the cap post 10, and stop when the bottom of the blind hole touches the upper end of the cap post 10, complete The installation of the drum cap 6, after inserti...

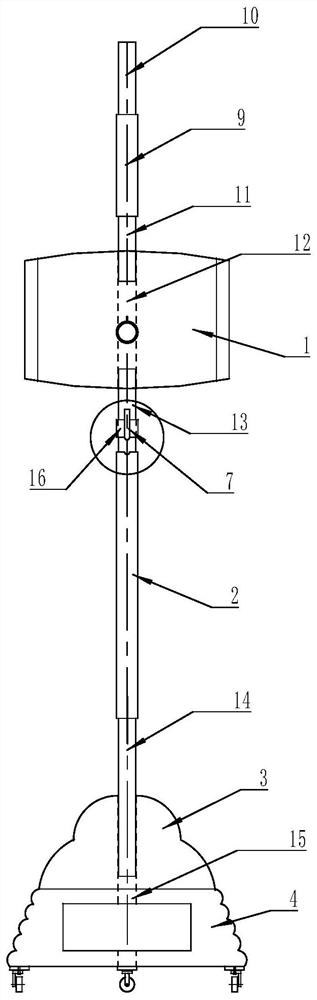

Embodiment 3

[0043] After the installation of the decoration is completed, the lower port of the drum core casing 12 of the built drum 1 is manually controlled to be nested corresponding to the lower insertion column 13, and the bottom of the built drum 1 stops when it touches the top of the built drum bracket 7, and the built drum 1 and the built drum are completed. Installation of the drum column 2; after the installation of the drum 1 and the drum column 2 is completed, the base inserting column 14 of the drum column 2 is inserted into the upper opening of the base sleeve 15 through manual control, and the bottom of the drum column 2 is inserted under the boss Stop when touching the top of the base casing 15, and complete the installation of the built-in drum 1; after the performance, when it is necessary to transition again, disassemble and load the vehicle according to the reverse order of the above-mentioned installation steps.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap