Metal alloy series-connected imbricated photovoltaic module cell string and preparation method thereof

A technology of metal alloys and photovoltaic modules, which is applied in the field of photovoltaic modules and its preparation, can solve problems such as fire, aging resistance, and resistance heating, and achieve the effects of accelerating molecular thermal movement, reducing failure probability, and reducing the light-receiving area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

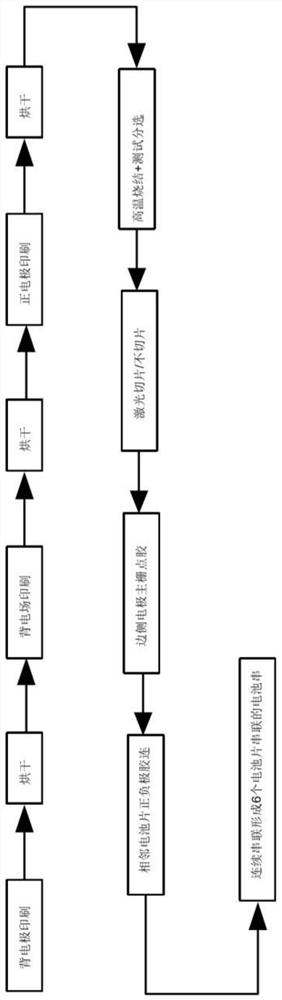

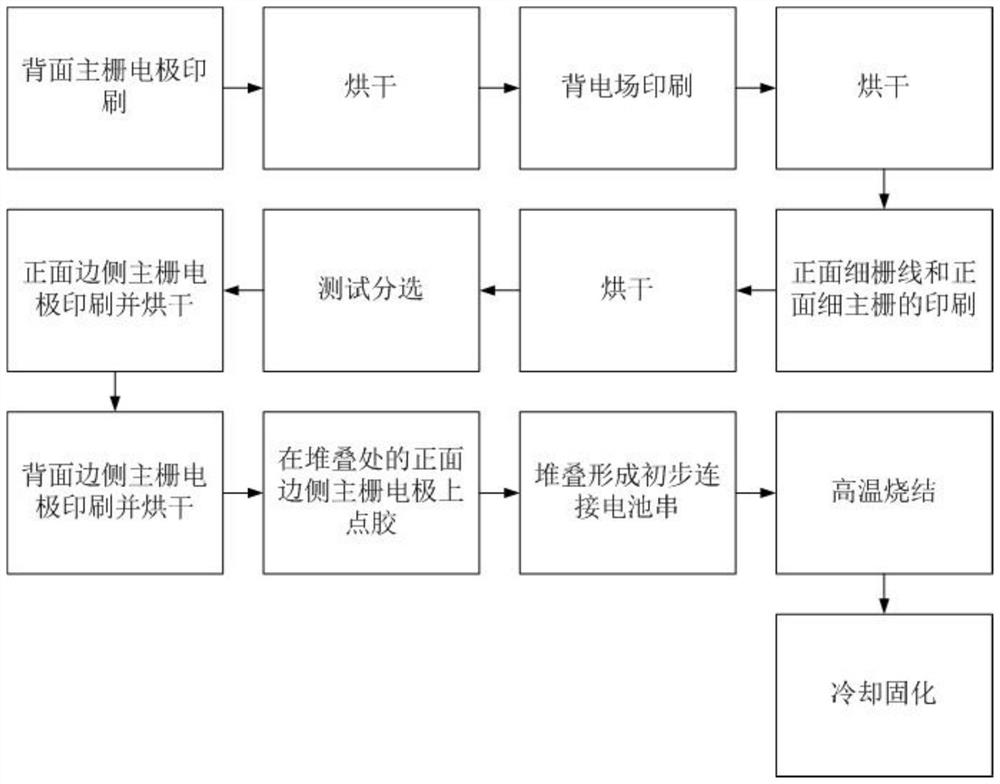

Method used

Image

Examples

Embodiment 1

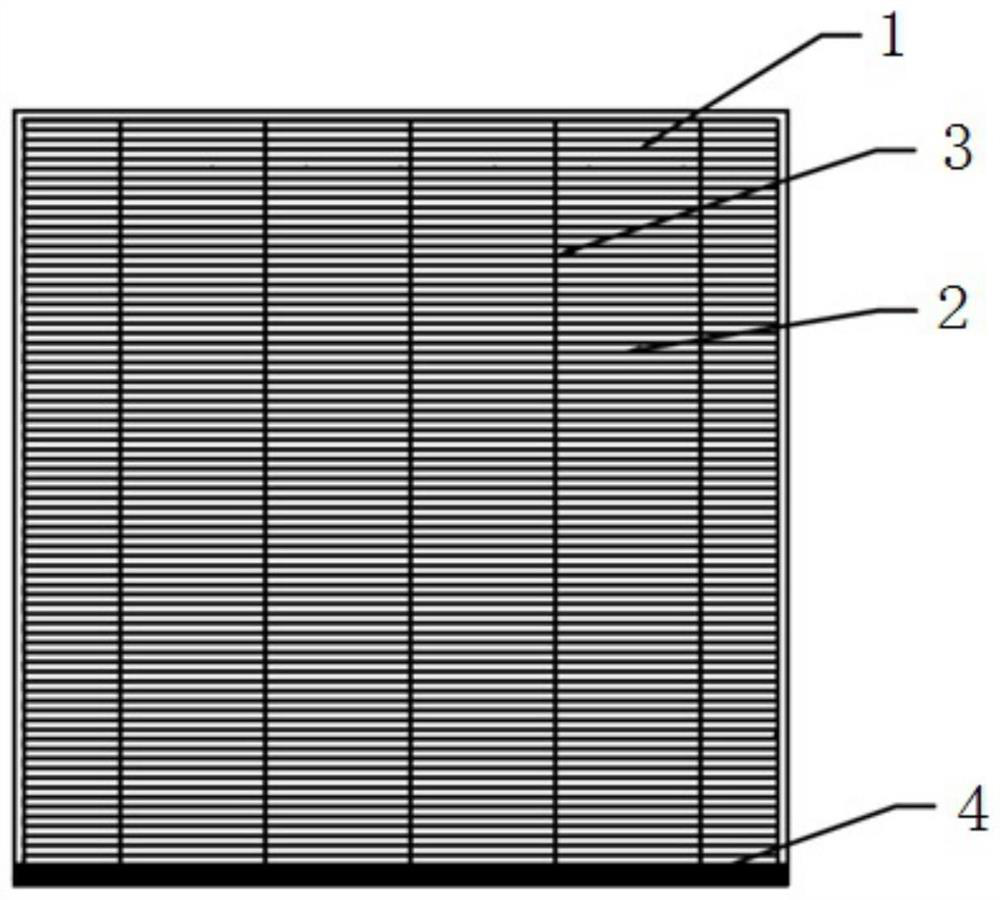

[0052] See Figure 3 to Figure 6 , the shingled photovoltaic module battery string connected in series by metal alloys in the present invention has six battery sheets 1; the front of each battery sheet 1 is provided with a front electrode, and the back of each battery sheet 1 is provided with a back electrode; the front The electrodes include a front fine grid electrode 2, a front main grid electrode 3 and a front side main grid electrode 4, wherein the front fine grid electrode 2 is connected to the front main grid electrode 3, and the front main grid electrode 3 is connected to the front side main grid electrode 4. connection; the back electrode includes the back main grid electrode 5, the back electric field 6 and the back side main grid electrode 7, and the back main grid electrode 5 is connected to the back side main grid electrode 7; The gate electrode 4 and the main gate electrode 7 on the back side of the next cell 1 are partially stacked and connected together by the ...

Embodiment 2

[0076] The components of the slurry for printing the front side busbar electrode 4 in step S8 of the present invention are: 80% ultra-fine silver powder, 3% glass phase, 15% acrylic polymer, 1.5% thickener, and 0.4% thixotropic agent , Defoamer 0.1%. Among them, ultrafine silver powder is used as the conductive functional phase.

[0077] Other technical characteristics are identical with embodiment 1.

Embodiment 3

[0079] In the present invention, before step S9, the back side busbar electrode 7 is not printed, and the front side busbar electrode 4 of the previous cell 1 is partially stacked with the back electrode of the next cell 1 to form a series connection.

[0080] Other technical characteristics are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com