Uniform impedance stub loaded suspended strip line cavity combiner

A technology of uniform impedance and combiner, used in circuits, waveguide devices, electrical components, etc., can solve problems such as increased debugging costs, different two-way debugging methods, and complex processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

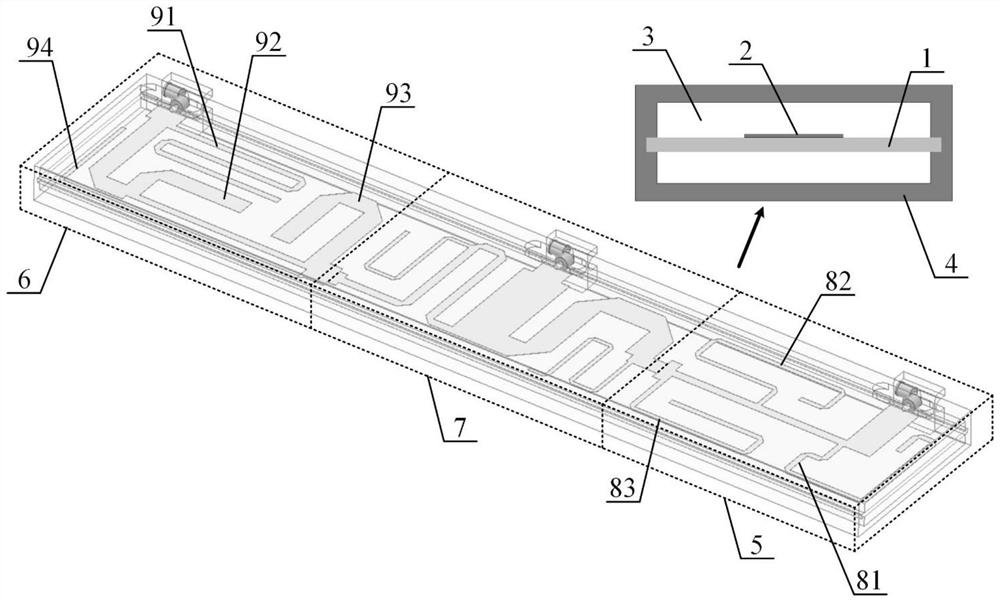

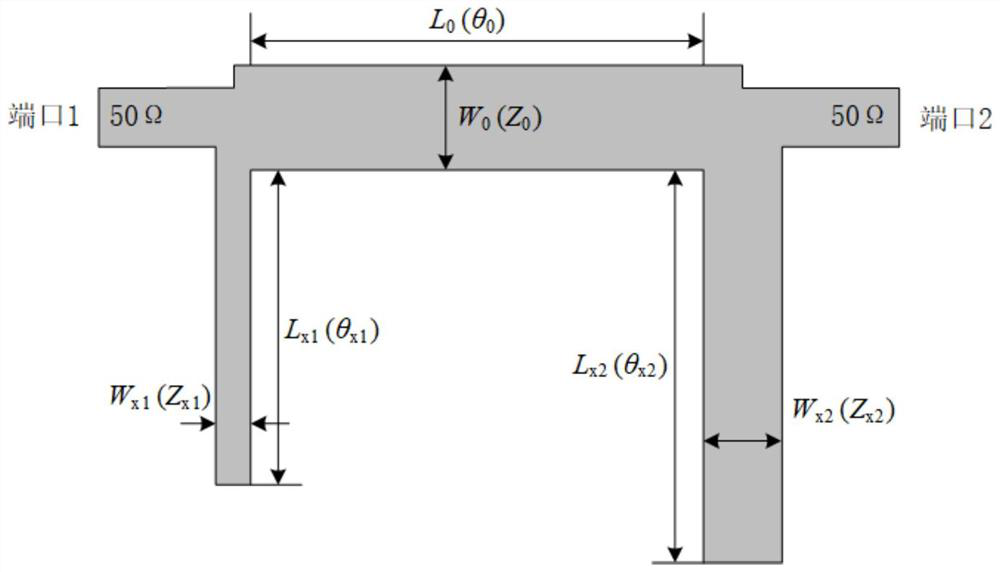

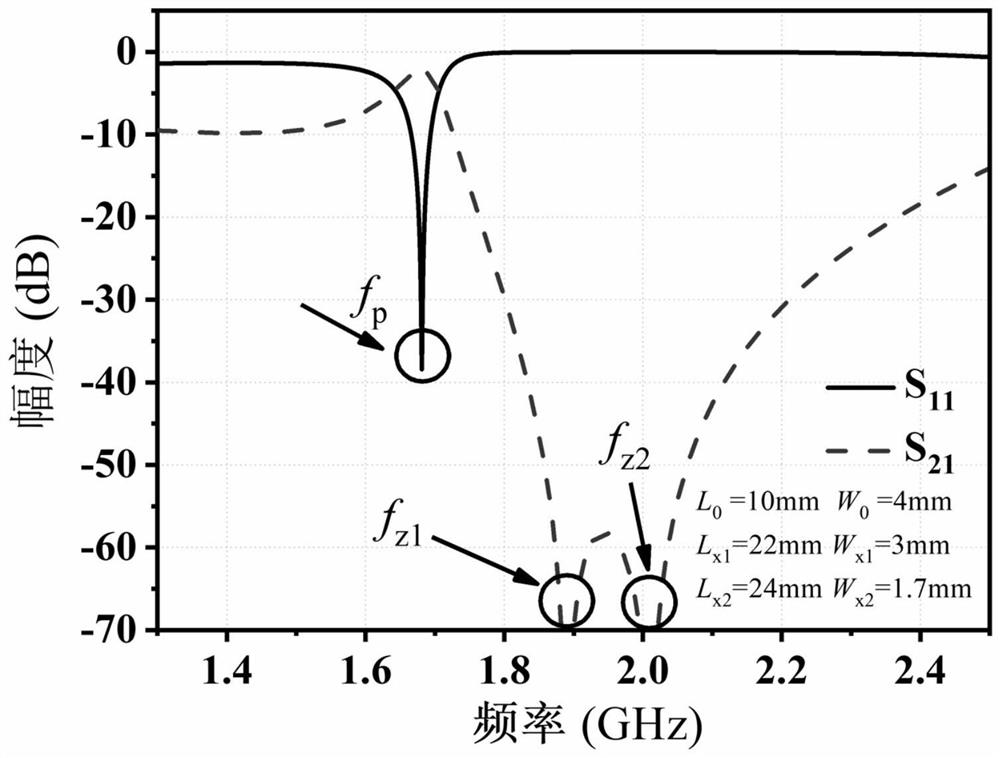

[0036] Such as figure 1 As shown, in this example, a suspended strip line cavity combiner with uniform impedance stub loading, a hollow metal cavity 4, a dielectric substrate 1 suspended and fixed in the metal cavity 4, and a substrate exposed to the air 3 above it The suspended stripline circuit 2, the suspended stripline circuit 2 includes a (7033MHz-798MHz) low-pass filter circuit 5, a (885MHz-960MHz) high-pass filter circuit 6 and a combining circuit 7. The low-pass filter circuit 5 includes a low-frequency input port, a low-frequency output port, a single π1-type structural unit, and a uniform impedance open-circuit stub 83 loaded on the low-frequency transmission line between the π1-type structural unit and the combining circuit 7. The uniform impedance open-circuit stub 83 makes A third zero point is generated in the low frequency band,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com