Few-slot multi-pole permanent magnet synchronous motor with magnetic separation structure

A permanent magnet synchronous motor and magnetic separation technology, which is applied in the direction of magnetic circuit shape/style/structure, magnetic circuit, electrical components, etc., can solve the problem of reducing the magnetic field intensity of coil induction, so as to improve the induction intensity of the coil, improve the efficiency of the motor, Avoid noise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The structural representation of the present invention will be described below in conjunction with the accompanying drawings.

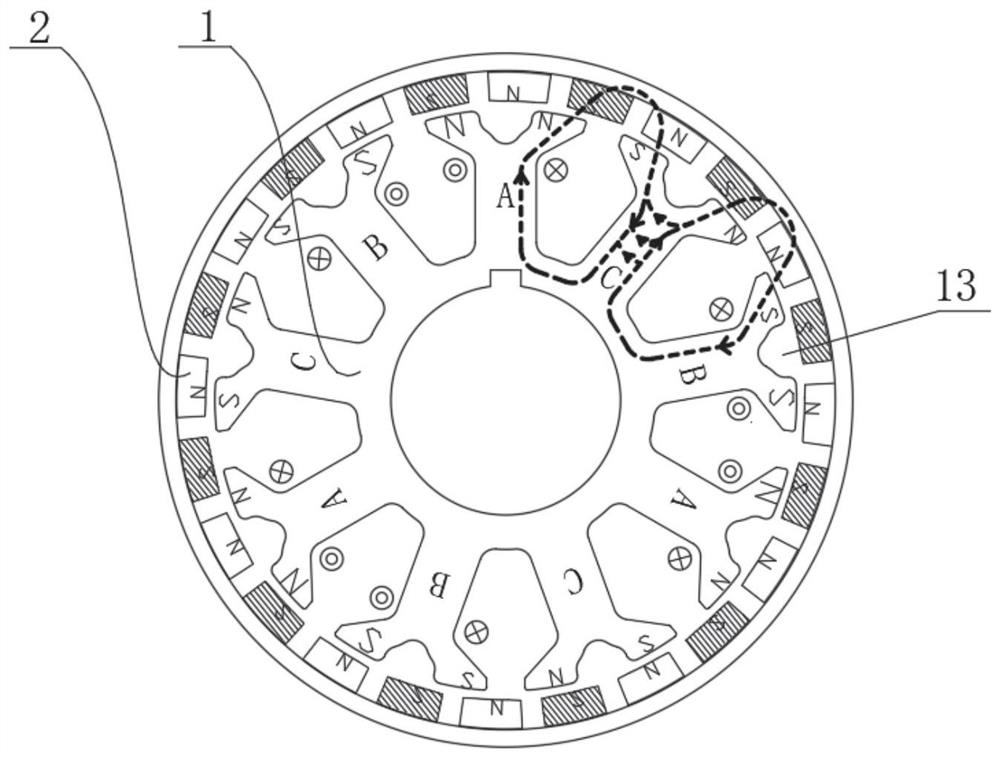

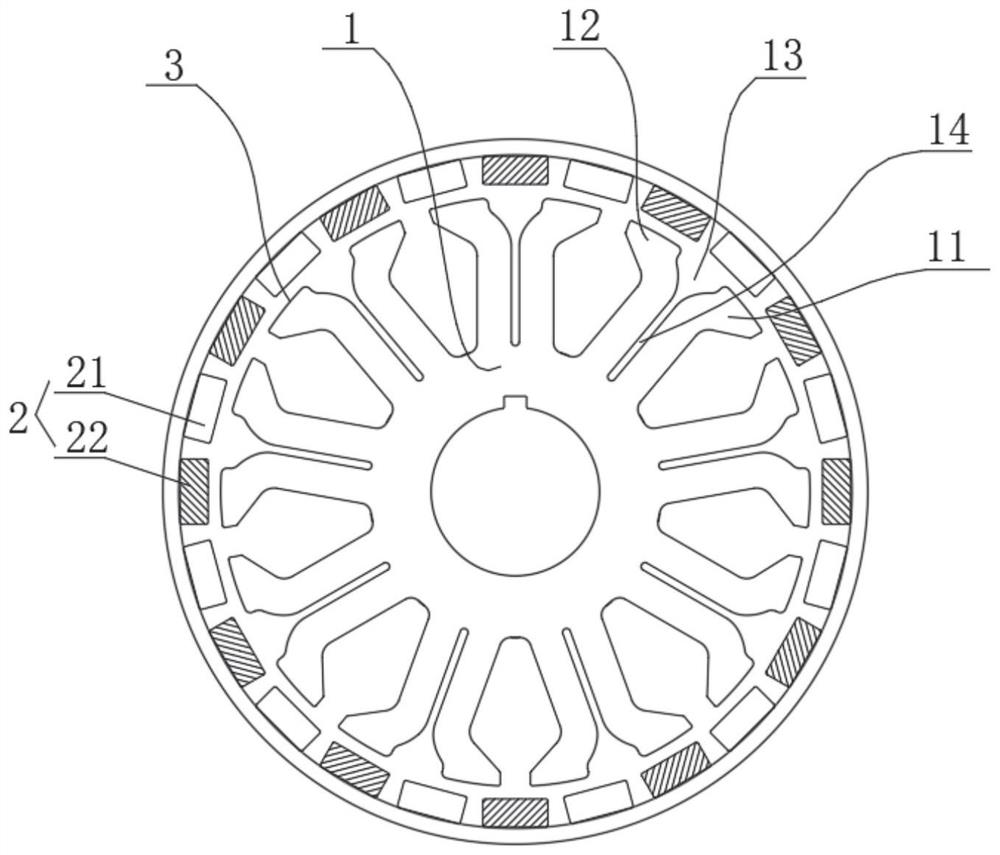

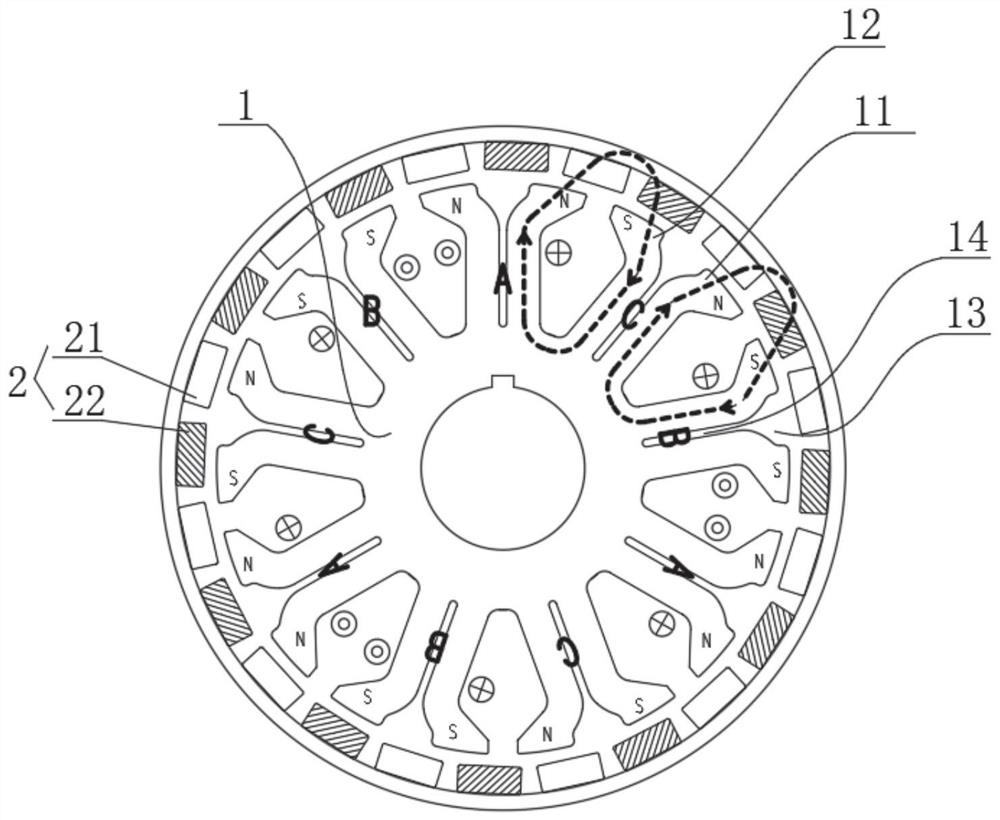

[0028] Such as figure 2 As shown, the few-slot multi-pole permanent magnet synchronous motor of the magnetic separation structure of this embodiment includes a stator core 1 and a rotor 2, the rotor 2 is an inner rotor or an outer rotor, and the rotor 2 includes S magnetic poles 21, N The magnetic pole 22, the top tooth gap 13 is formed at the tooth tip of each stator tooth of the stator core 1, the top tooth gap 13 expands the air gap between the tooth top and the rotor 2, and extends from the bottom of the top tooth gap 13 to the tooth root A root gap 14 is formed, and a top gap 13 and a root gap 14 separate the stator teeth into left unit teeth 12 and right unit teeth 11 , so that the magnetic circuit between the left unit teeth 12 and the right unit teeth 11 is disconnected.

[0029] In the above embodiment, the width of the top tooth gap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com