Feed putting all-in-one machine for livestock breeding

An all-in-one machine and feed technology, applied in animal husbandry, application, poultry industry and other directions, can solve the problems of affecting the appetite of livestock, long feed accumulation time, damage and other problems, and achieve the goal of reducing labor intensity and the number of manual use, and reducing the cost of feeding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

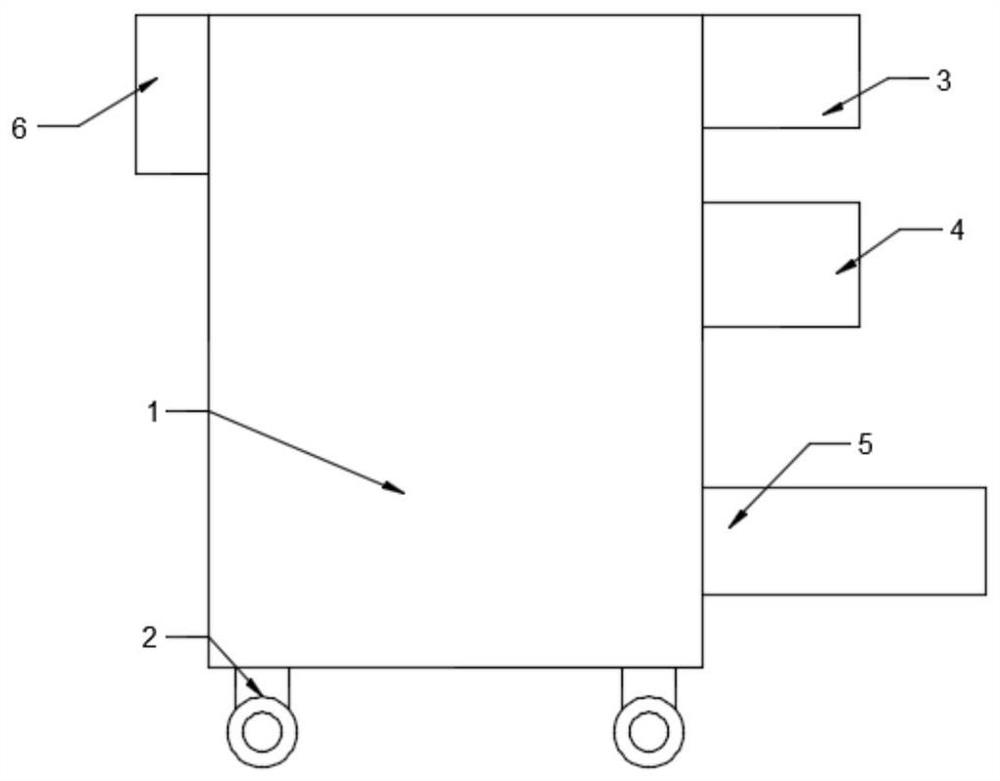

[0027] see Figure 1-7 , in the embodiment of the present invention, a kind of feed all-in-one machine for animal husbandry, comprising: movable chassis 1, universal wheel 2 is installed on the bottom of described movable chassis 1, and the upper side of described movable chassis 1 is provided with control Box 6, the upper part of the other side of the movable cabinet 1 is fixed with a feed mixing mechanism 3, the movable cabinet 1 at the lower part of the feed mixing mechanism 3 is fixed with a feed receiving mechanism 4, and the lower part of the feed receiving mechanism 4 A feed dispersing delivery mechanism 5 is provided.

[0028] In this embodiment, the feed dispersing and feeding mechanism 5 can move up and down on the chassis of the movable cabinet 1, so as to facilitate feed feeding to feed troughs of different heights.

Embodiment 2

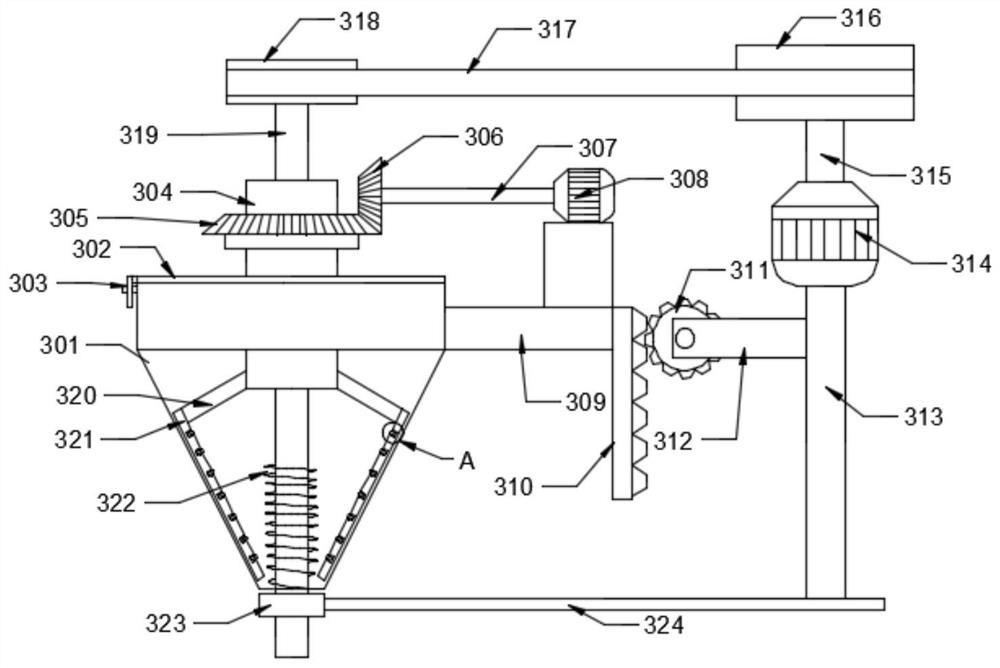

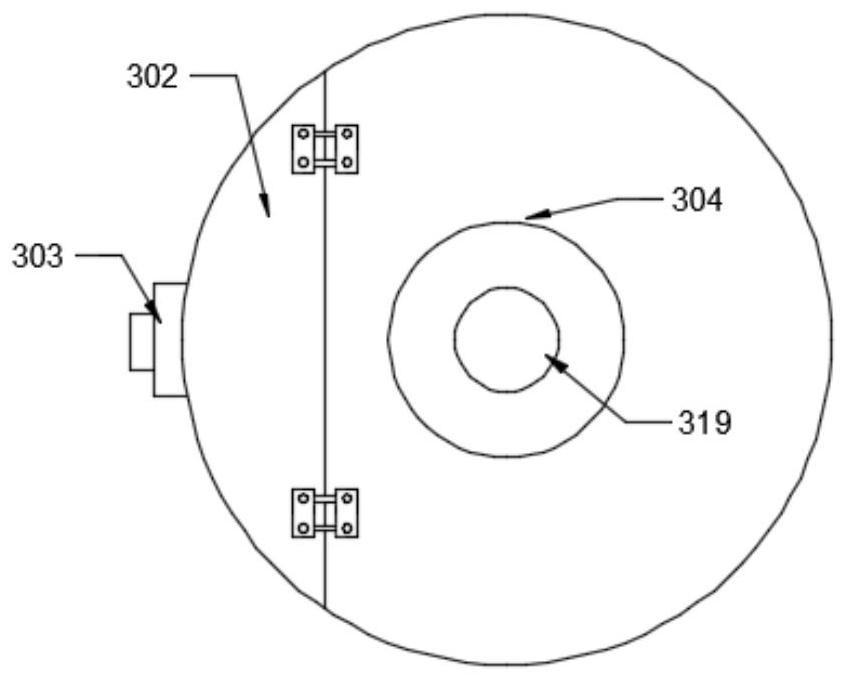

[0030] see Figure 1-7 , in this embodiment, the feed stirring mechanism 3 includes: a stirring tank 301, a cover plate 302 is hinged on the upper part of the stirring tank 301, a lock 303 is fixed on one side of the cover plate 302, and the middle of the upper part of the stirring tank 301 The position is provided with a hollow column 304, a first bevel gear 305 is fixed on the outer middle of the hollow column 304, a second bevel gear 306 is meshed on one side of the first bevel gear 305, and a second bevel gear 306 is installed on the second bevel gear 306. A rotating shaft 307, the other end of the first rotating shaft 307 is connected with a first motor 308; the outer side of the mixing tank 301 is fixedly connected with an extension plate 309, and the end of the extension plate 309 is fixed with a rack 310, so One side of the rack 310 is meshed with a gear 311, and one side of the gear 311 is connected to a first connecting plate 312, and the other end of the first conne...

Embodiment 3

[0034] see Figure 1-7 , in this embodiment, the feed receiving mechanism 4 includes: a fan wheel plate 411, a first fixed block 401 is provided on one side of the fan wheel plate 411, and a first rotating rod 402 runs through the first fixed block 401 , the other end of the first rotating rod 402 is fixed with a hollow block 408, the upper part of the first fixed block 401 is fixed with a connecting pipe 403, and the other end of the connecting pipe 403 is fixed with a second fixed block 404, and the second fixed block 401 is fixed with a connecting pipe 403. A third rotating shaft 405 runs through the block 404, a crank 406 is fixedly connected to the end of the third rotating shaft 405, the other end of the crank 406 is provided with a first rotating pin 407; Rod 409, the first rotating pin 407 is rotatably connected to one end of the long rod 409, the connection between the first rotating pin 407 and the long rod 409 is fixedly connected with a fork plate 410, and the blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com