Lathe capable of automatically controlling workpiece clamping force and working method thereof

A technology of automatic clamping and clamping force, which is applied in the field of lathes to avoid deformation, improve work efficiency, and have wide applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

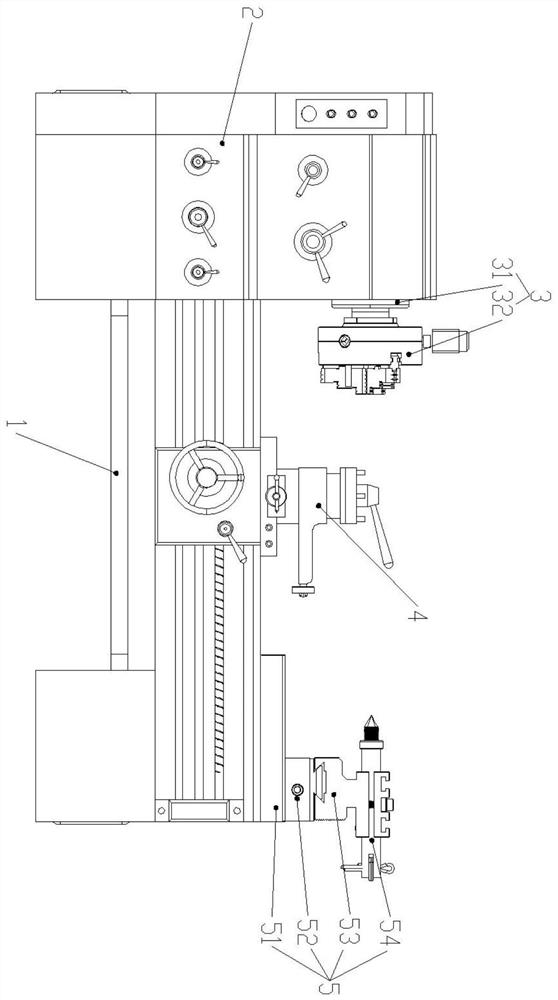

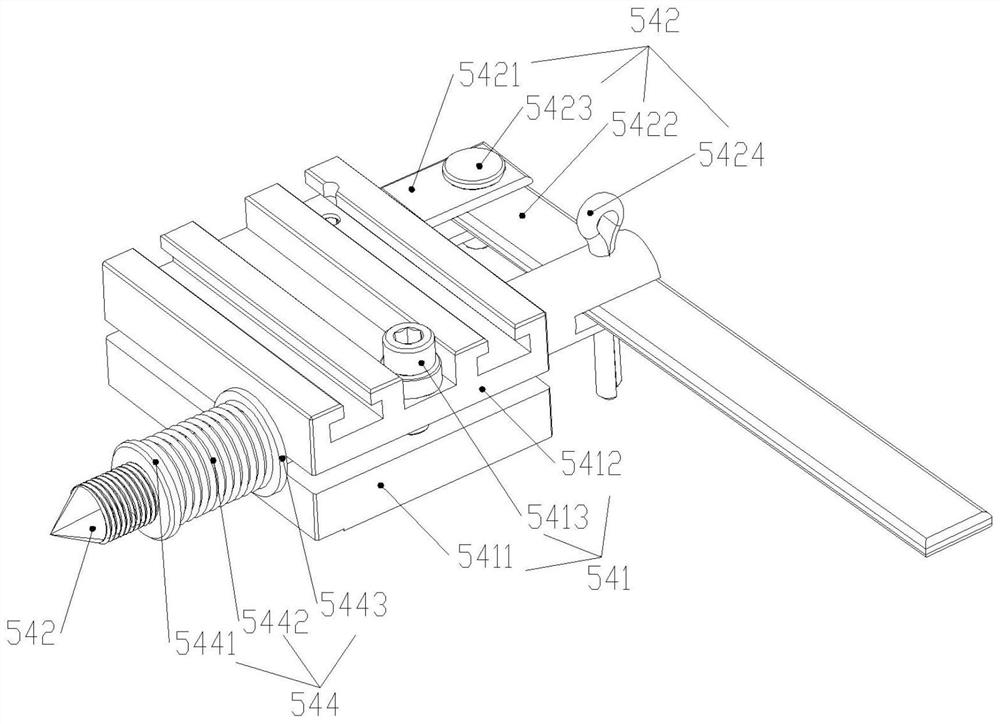

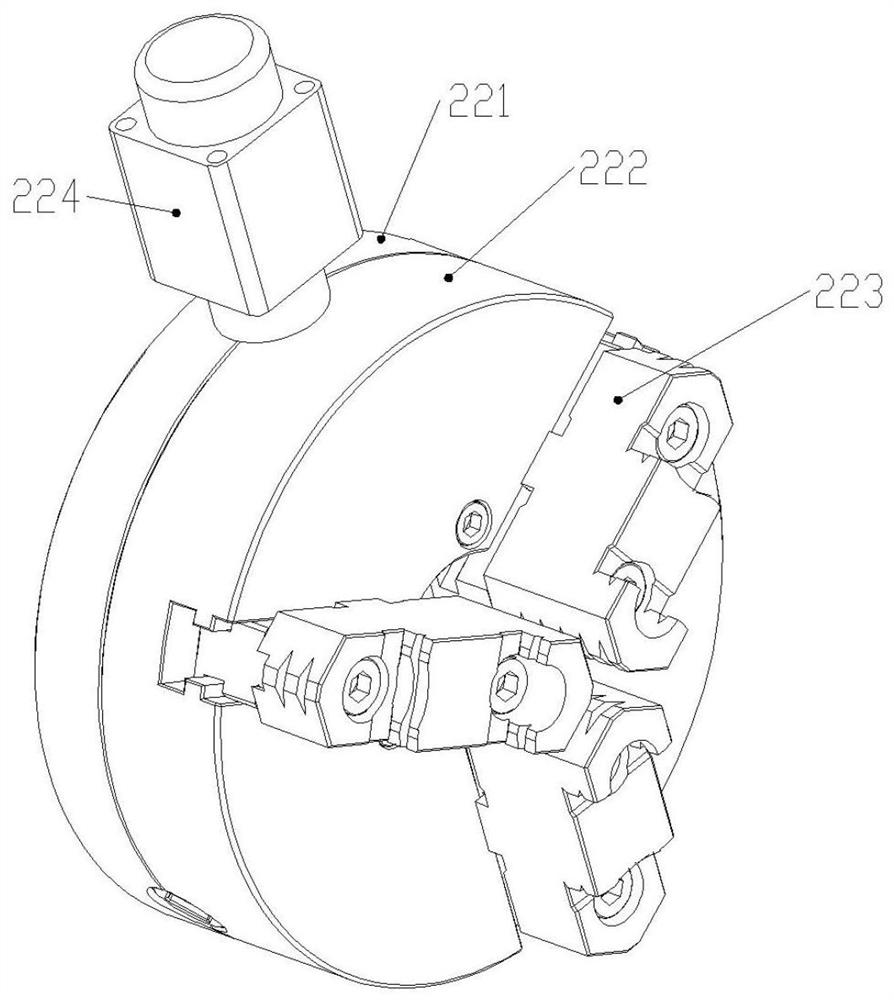

[0036] Such as figure 1 Shown is a front view of the present invention, including a lathe fixing seat 1, an end fixing structure 2, a feed structure 3, a tool rest structure 4, and a tailstock structure 5, and the end fixing structure 2 is arranged at the end of the lathe fixing seat 1 part, the feed structure 3 is arranged on the side of the lathe fixed seat 1, the tool rest structure 4 is arranged on the feed structure 3 above the lathe fixed seat 1, and the tailstock structure 5 is arranged on the lathe fixed seat 1 The other end away from the end fixing structure 2; the end fixing structure 2 includes a main shaft structure 21 and a chuck fixing structure 22, and the chuck fixing structure 22 is arranged at one end of the main shaft structure 21; the tailstock structure 5 includes a tail Seat guiding platform 51, first moving structure 52, second moving structure 53 and tail tightening structure 54, described first moving structure 52 is arranged on the tailstock guiding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com