Drilling machine flat tongs and manufacturing method thereof

A technology of vise and drilling machine, which is applied in the direction of manufacturing tools, components of boring machine/drilling machine, drilling/drilling equipment, etc., can solve the problems of increasing the process requirements of processing, affecting the performance of the vise, increasing the loosening of bolts, etc. High friction, beautiful appearance, and smooth sliding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

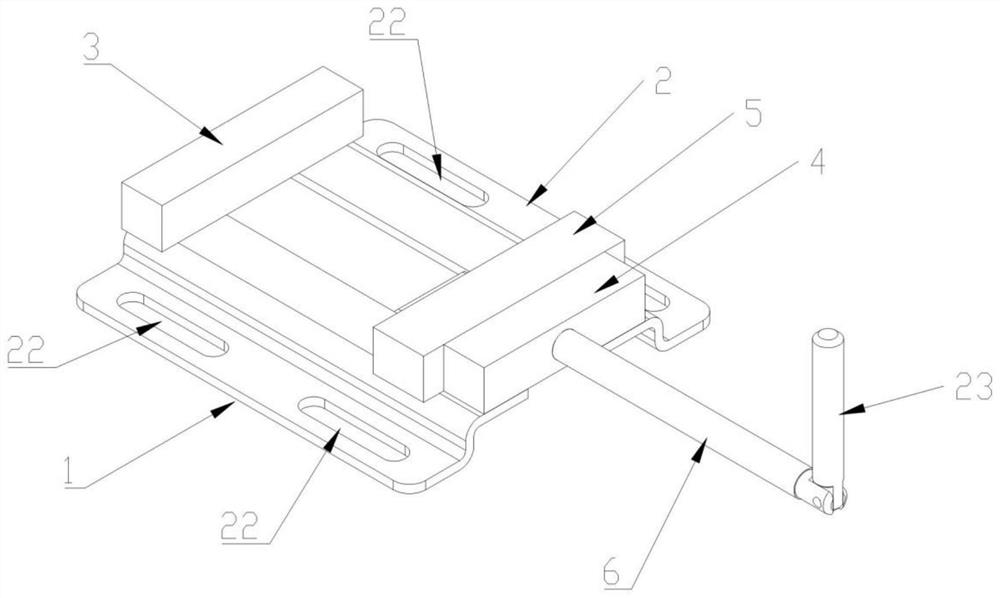

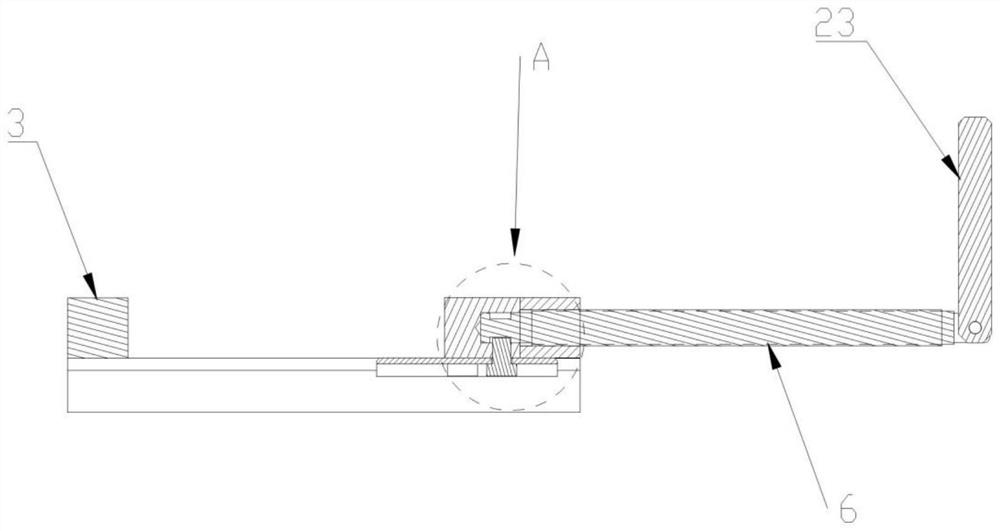

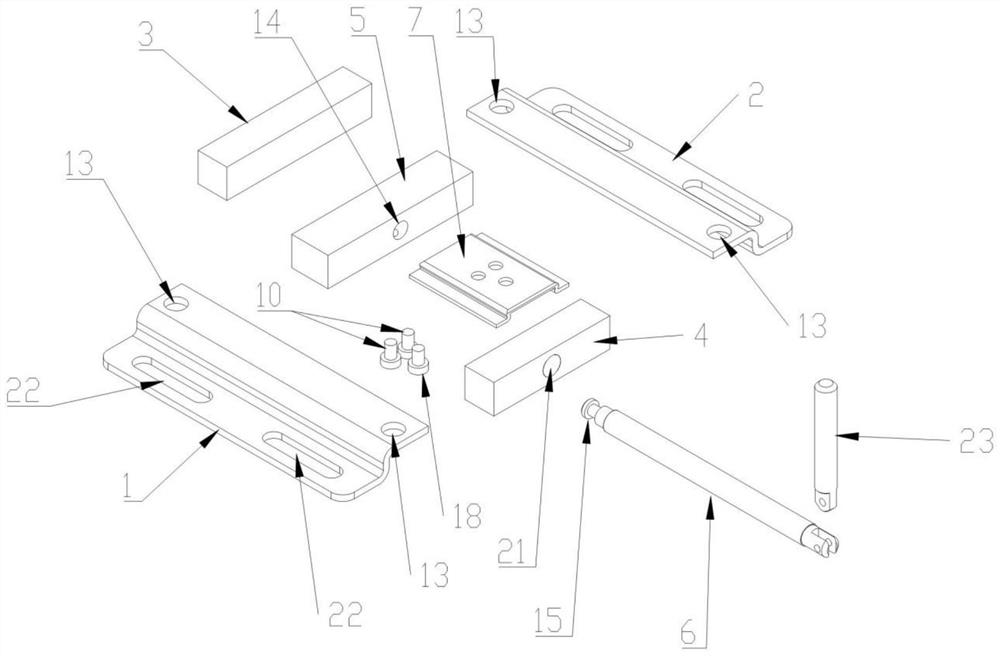

[0067] Such as Figure 1 to Figure 9 As shown, the drilling machine vise and its manufacturing method of the present invention include: a first slide rail 1 and a second slide rail 2 arranged in parallel, the first slide rail 1 and the second slide rail 2 are in opposite directions, and also That is, the first slide rail 1 and the second slide rail 2 are arranged side by side as mirror images; it also includes a fixed jaw 3, which is arranged above one end of the first slide rail 1 and the second slide rail 2, and is aligned with the first slide rail and the second slide rail. The second slide rail is fixedly connected; and comprises nut 4, and described nut 4 is the nut that a profile is cuboid shape in this embodiment, certainly can also be replaced with other shape, also can be replaced with the nut 4 of conventional shape, it Set above the other end of the first slide rail 1 and the second slide rail 2, and fixedly connected with the first slide rail 1 and the second slide...

Embodiment 3

[0082] Such as Figure 7 As shown, another exemplary embodiment of the present invention's drill press vise and its manufacturing method; including the schemes of the above-mentioned embodiment 1 and embodiment 2, on the basis of the implementation of embodiment 1 and embodiment 2, the second embodiment can also be omitted For the second slide plate 11 and the third slide plate 12, the first slide plate 7 is processed into an "Ω" shape at one time, so as to replace the above-mentioned embodiment. At the same time, the key point is to maintain the "Ω" shape, so that there will be no influence between the corners on both sides above it and the first slide rail 1 and the second slide rail 2, so that the sliding connection is more consistent, and at the same time, the advantage is that : It avoids the shortcoming of using the traditional stamping scheme to make the first slide plate 7, which will cause a rounded corner on both sides, and the rounded corner is easy to interfere wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com