Double-station rotary clamp for finish turning of semicircles of brake bases

A rotary fixture and double station technology, applied in the direction of manufacturing tools, clamping, positioning devices, etc., can solve the problems of inability to use mass production, poor flexibility, low work efficiency, etc., to achieve strong versatility, simple installation, improved The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

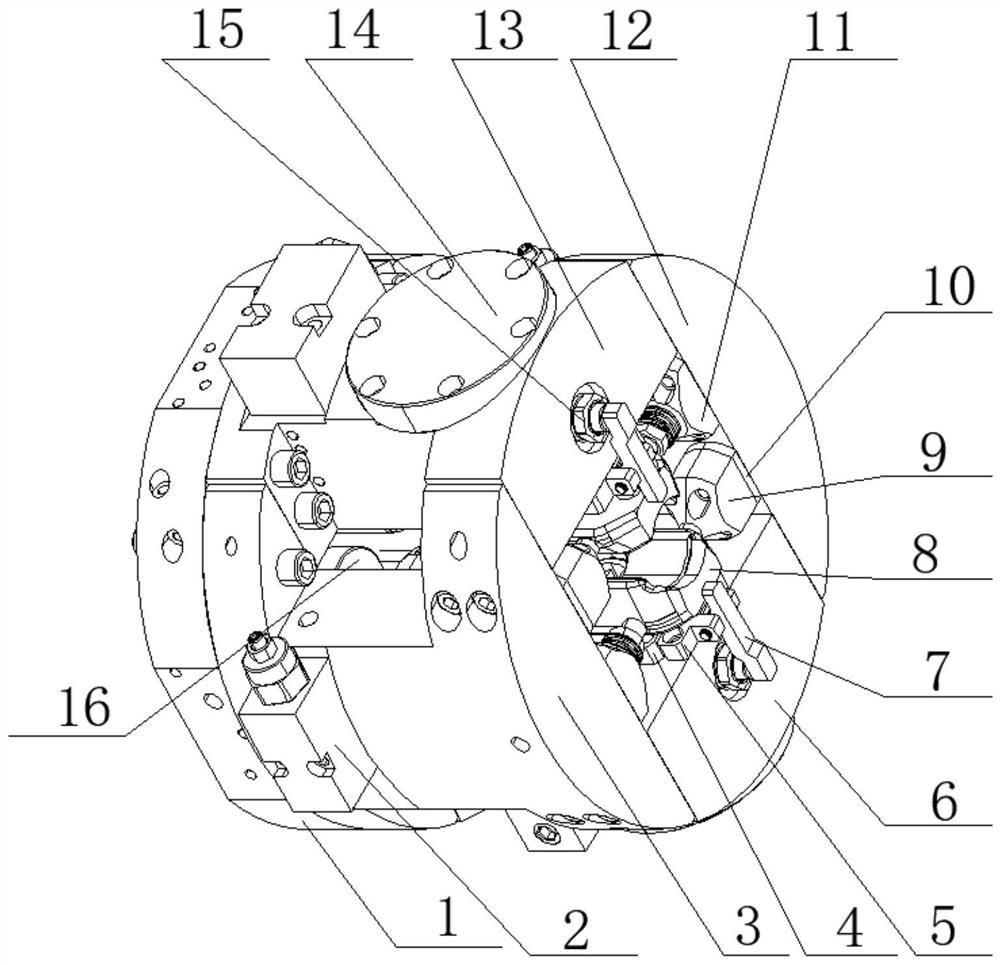

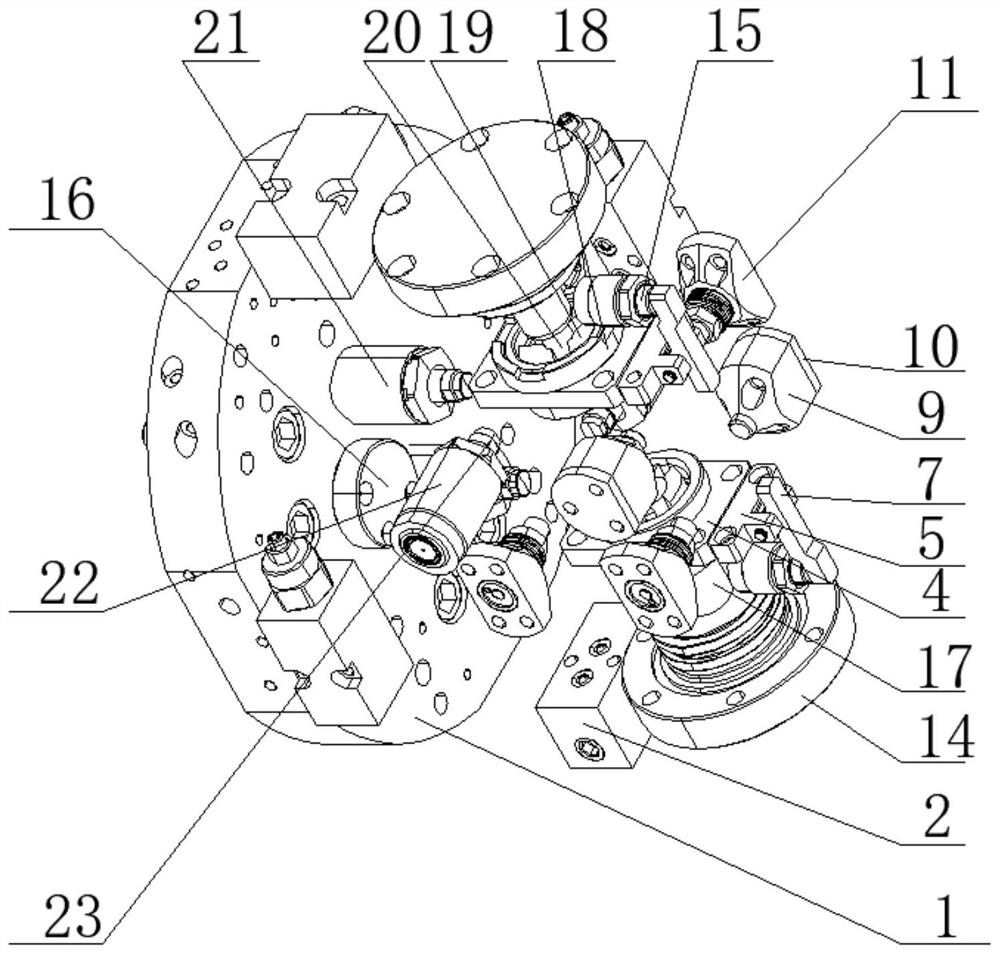

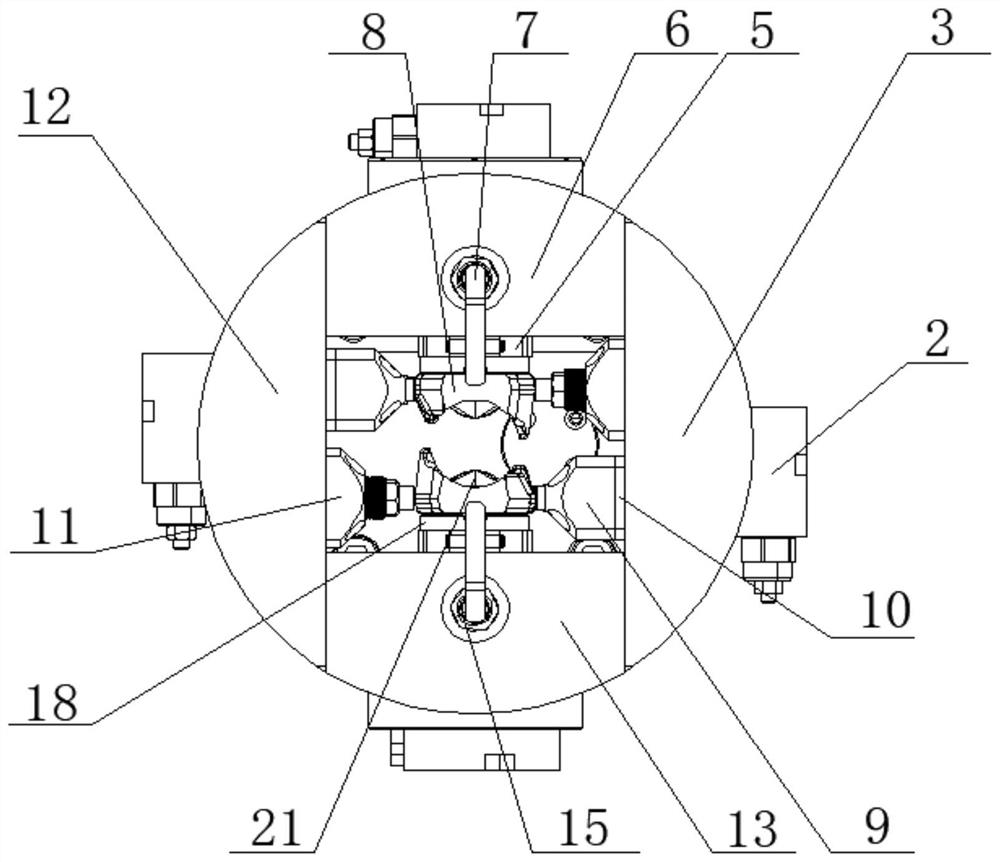

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] Such as Figure 1-4 As shown in the figure, a double-station rotary fixture for semi-circular brake base finishing includes a connecting plate and a disc arranged on the spindle of the machine tool. The connecting plate and the disc 1 are connected by bolts, and the front and rear ends of the disc 1 are provided with a second One oil cylinder seat 3, the second oil cylinder seat 12, the upper and lower ends of the disc 1 are provided with a first positioning seat 6 and a second positioning seat 13, the first oil cylinder seat 3, the second oil cylinder seat 12, the first positioning seat 6 and the second positioning seat 13 are equipped with a horizontal clamping device, the horizontal clamping device includes a pressing plate 7, a support 9, an adjusting gasket 10, a push cylinder seat 11, a pressing cylinder 15, a first horizontal support cylinder 22, a floating su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com