Cloth two-way composite production line and textile fabric composite production line

A textile fabric and production line technology, which is applied in the field of textile fabric composite production line and fabric two-way composite production line, can solve the problems of high cost investment, large production line area, and many divisions of work sections, and achieve high configuration cost and large floor area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

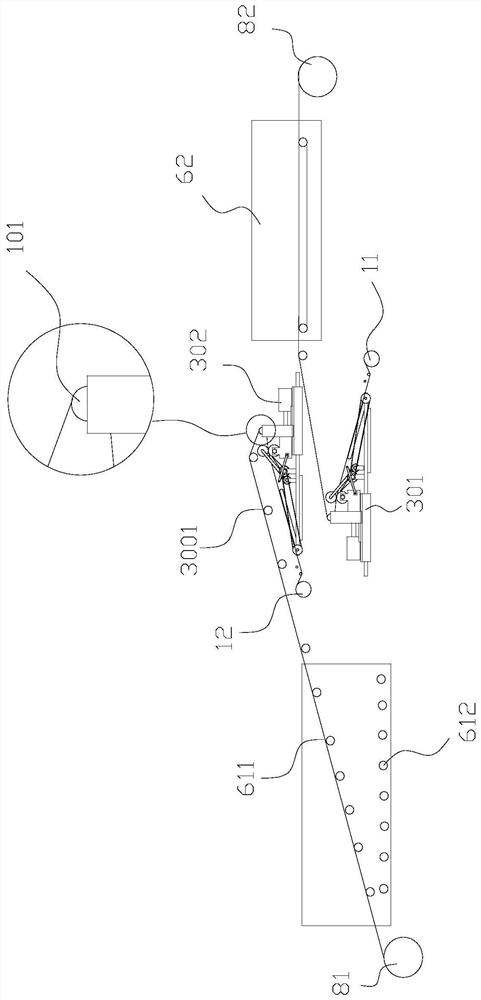

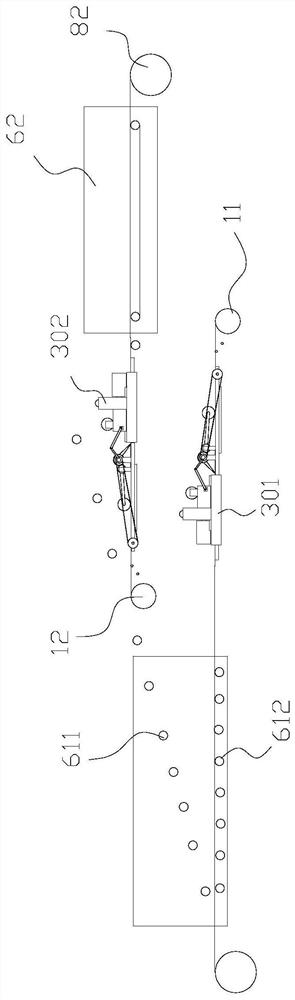

[0065] Such as figure 1 , 2 As shown, this embodiment discloses a two-way composite production line for cloth, including a first composite production line and a second composite production line, and the first composite production line is located below the second composite production line.

[0066] The first composite production line includes the first unwinding device 11 , the first coating machine 301 , the first oven, and the first winding device 81 from front to back according to the sequence of the process flow.

[0067] The second composite production line includes the second unwinding device 12 , the second coating machine 302 , the second oven 62 , and the second winding device 82 from back to front according to the sequence of the process flow.

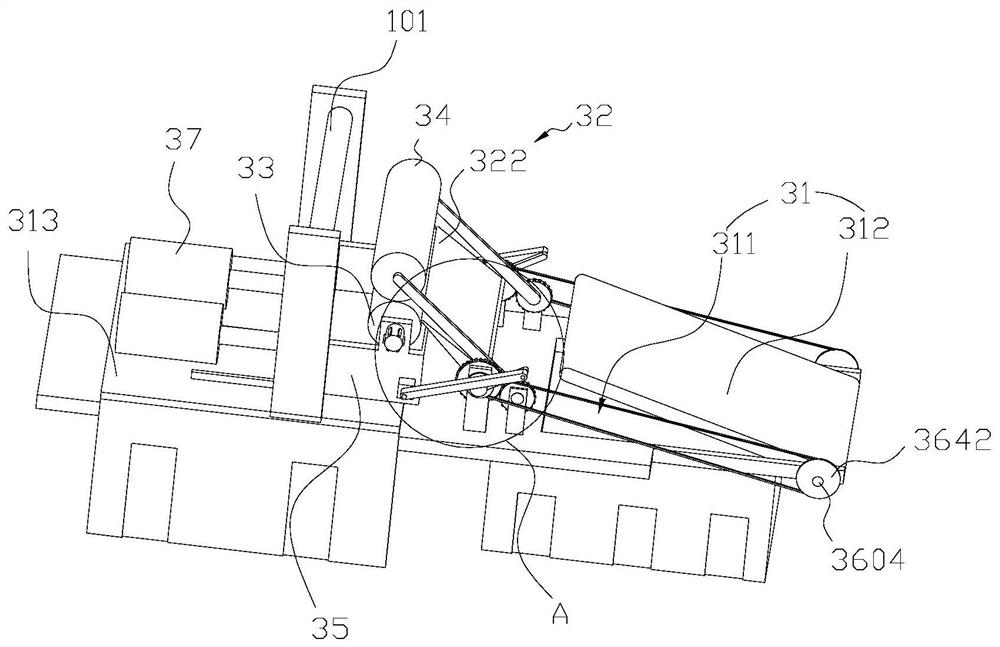

[0068] Such as image 3 , 4 As shown, both the first coater 301 and the second coater 302 include a working platform 31 , a scraper 32 , an upper rubber roller 33 , a back roller 34 , and a trough 35 . In this embodiment, ...

Embodiment 2

[0084] Such as image 3 , 4 , 7, and 8, this embodiment discloses a textile cloth composite device, which includes an unwinding device 1, a coating machine 3, a composite device 4, an oven 6, and a winding device 8 in sequence according to the process flow. The top rubber roller 33 is in rotation with the material chute 35 . The coating machine 3 includes a working platform 31 , a scraper 32 , an upper rubber roller 33 , a back roller 34 , and a trough 35 . The feeding end of the working platform 31 is provided with a guide plate opening slot 311 leading up and down, and the connecting end of the guide plate 312 is rotatably matched with the guide plate opening slot 311 .

[0085] A first guide roller 101 is provided between the composite device 4 and the coating machine 3 , and a second guide roller 102 is provided between the oven 6 and the composite device 4 . The second guide roller 102 can slide up and down in the vertical direction.

[0086] by image 3 The left sid...

Embodiment 3

[0103] Such as image 3 , 4 , 11, the difference between the embodiment and the foregoing embodiment is that an upper platform 313 is also fixed above the discharge end of the working platform 31, and there is a strip-shaped material between the upper platform 313 and the discharge end of the first working platform 31. Delivery channel 314 . The trough 35 is arranged on the upper platform 313 and is slidingly matched with the upper platform 313 .

[0104] The top of the working platform 31 is provided with a first rotating shaft 361, the scraper 32 is fixed on the first rotating shaft 361, and the first rotating shaft 361 is rotatably matched with the scraper frame. Also comprise connecting arm 362, transmission rod 363, one end of connecting arm 362 is fixed on the first rotating shaft 361, the other end of connecting arm 362 is hinged with one end of transmission rod 363, and the other end of transmission rod 363 is hinged with trough 35.

[0105] The guide plate rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com