Flexible connection rotor cabin helicopter

A technology of flexible connection and rotor compartment, which is applied in the directions of rotorcraft, motor vehicles, aircraft, etc., can solve the problems of high transmission power, complex manipulation, and heavy transmission components, and achieve the effect of large load capacity, flexible manipulation and weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

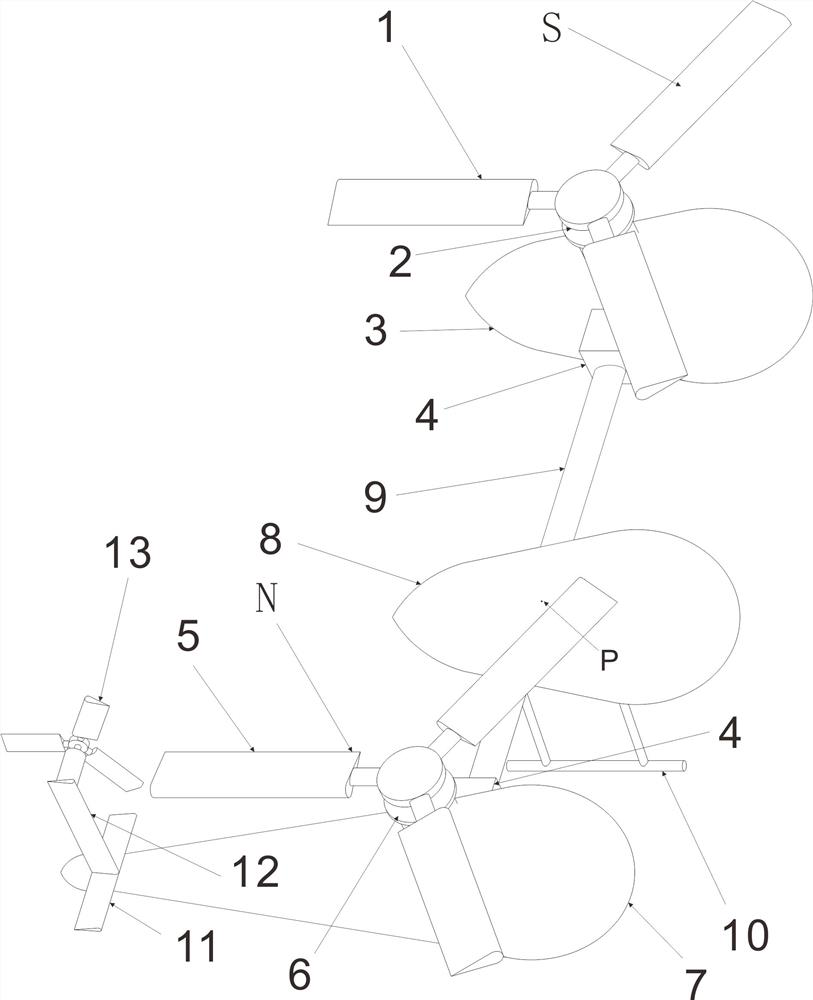

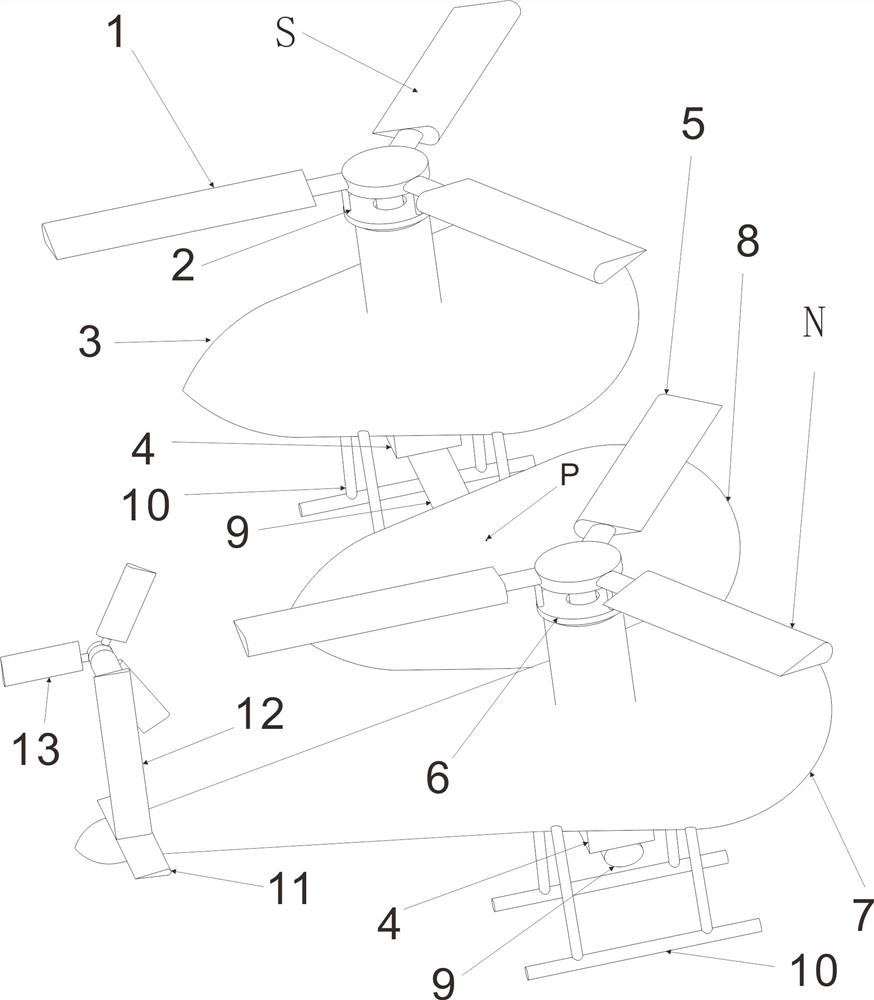

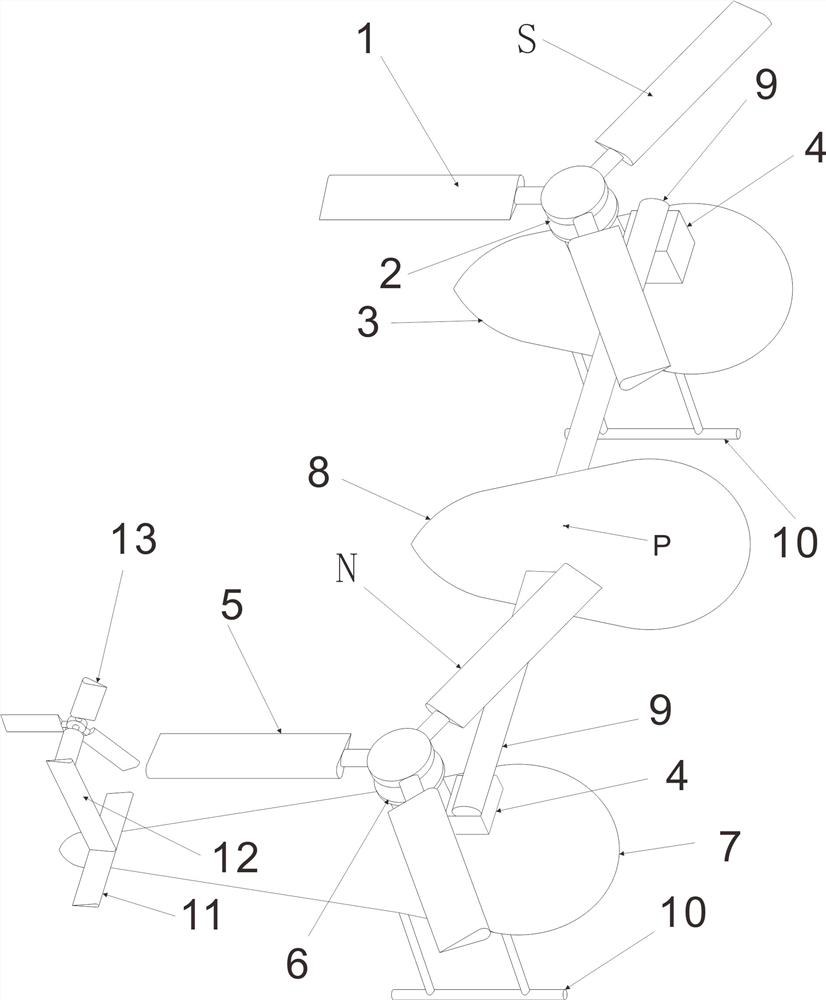

[0069]figure 1 In the illustrated embodiment, the lower portion of the body warehouse 8 is disposed near the center of the body 10, the left side of the body warehouse 8 is connected to the rigid beam 9, the left end of the rigid beam 9 connects the right flexible member 4, the body warehouse 8 On the right, the rigid beam 9 is connected. The right end of the rigid beam 9 is connected to the left flexible member 4 of the tail rotor wing boon 7, and the left-rotor 1 provided on the left rotor wrap 3 is clockwise, and the right side of the tail rotable wing 7 is set. The rotor 5 counterclockwise reverse N, the tail of the tail rotor wing bun 7 is provided with the tail propeller 13 of the rotating surface of the right rotor 5, the horizontal tail 11, and the vertical tail 12, and the tail propeller 13 is connected to the transmission, from the drive rotor Engine or motor simultaneously drivers.

[0070]The rotor warehouse 3 is provided on the left rotor bin 3, the rotary axis is driven, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com