Workpiece transfer device for machining

A transfer device and mechanical processing technology, applied in the direction of conveyor objects, mechanical conveyors, transportation and packaging, etc., can solve problems such as relative displacement of conveyor belts, and achieve the effects of improved transfer efficiency, cost saving, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

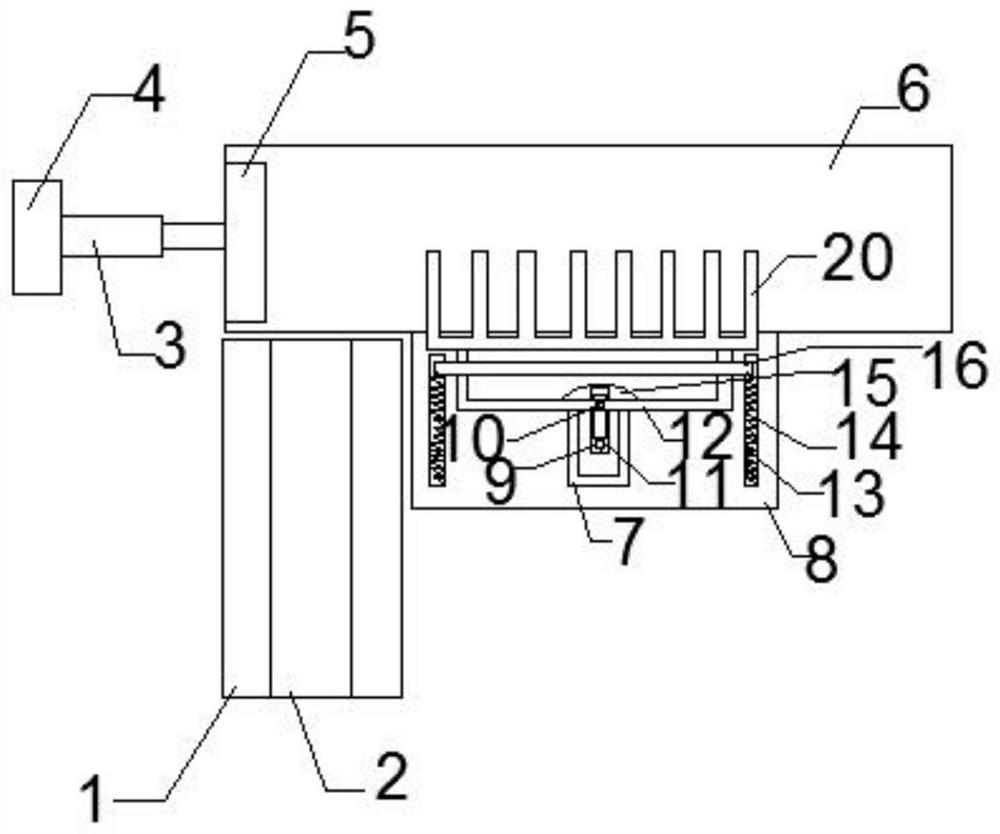

[0033] Such as figure 1 As shown, the transmission device includes a conveyor belt 2. Baffle plates 1 are provided on both sides of the conveyor belt 2. The baffle plate 1 is higher than the conveyor belt 2. One end of the conveyor belt 2 corresponds to the transfer table 6. The transfer device is used to transport the workpiece to the transfer table 6.

[0034] Pushing device comprises: base 4, base 4 top is provided with push rod 3, and the free end of push rod is provided with push block 5. The height of the base 4 is set to match the height of the transfer platform 6 . Pushing device is used for pushing the workpiece of transfer table 6 into the first small "U" shaped frame.

[0035] The transfer device, the transfer device includes: a horizontal plate 8, the horizontal plate 8 is arranged at the bottom of the transfer platform 6, there is a pole 17 supporting the transfer platform 6 at the bottom of the horizontal plate, the first rectangular slide rail 7 is arranged on ...

Embodiment 2

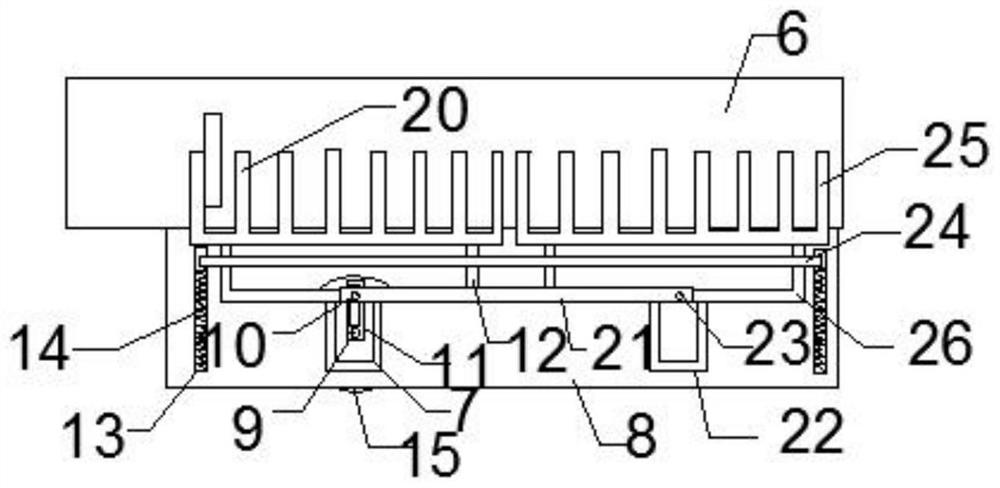

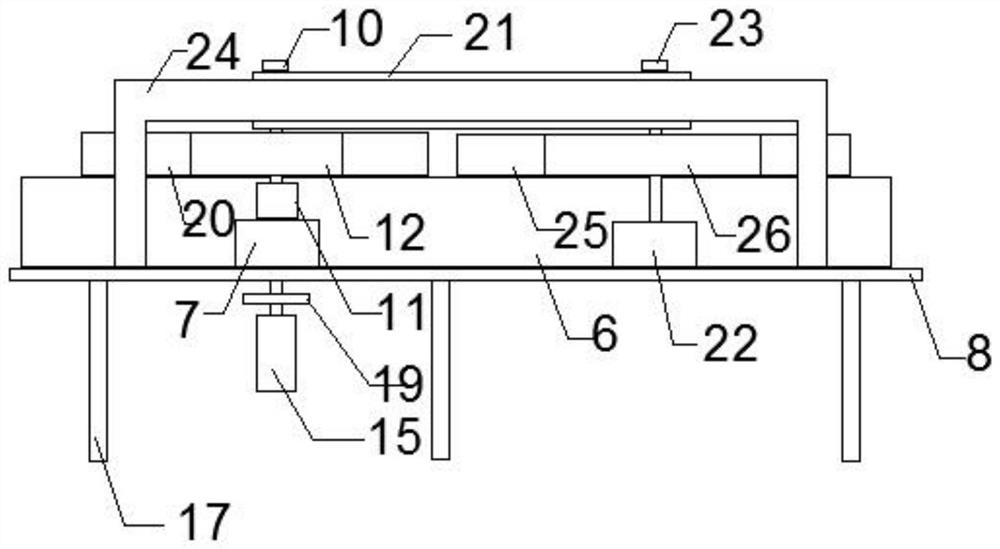

[0037] Such as figure 2 and 3 As shown, on the basis of Embodiment 1, the transfer device also includes a shipping device on the same side of the transfer platform, including: a second rectangular slide rail 22 on which a second slide block 23 is slid A second "U"-shaped frame 25 is arranged above the second slider 23, and a connecting rod 21 is connected between the first slider 10 and the second slider 23. The second "n" type limit rod 24 is slidably arranged on the transfer platform 6 and is located above the first "U" type frame 20 and the second "U" type frame 25.

Embodiment 3

[0039] On the basis of Embodiments 1 and 2, the bottom ends of the first "n" type limit rod 16 and the second "n" type limit rod 24 are provided with "I" type slide rails, and the "I" type slide rails Slide in groove 13, be provided with spring 14 between " I " type slide rail and chute 13 one ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com