Spinning method and spinning device for transverse motion twisting on three-roller ring throstle

A technology of roller ring spindle and spinning frame, which is applied to spinning machines, textiles, papermaking, drafting equipment, etc. It can solve the problems of accidental drafting of rubbing rollers, reduce the deterioration of evenness performance and ensure stability , Enhance the effect of curl cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

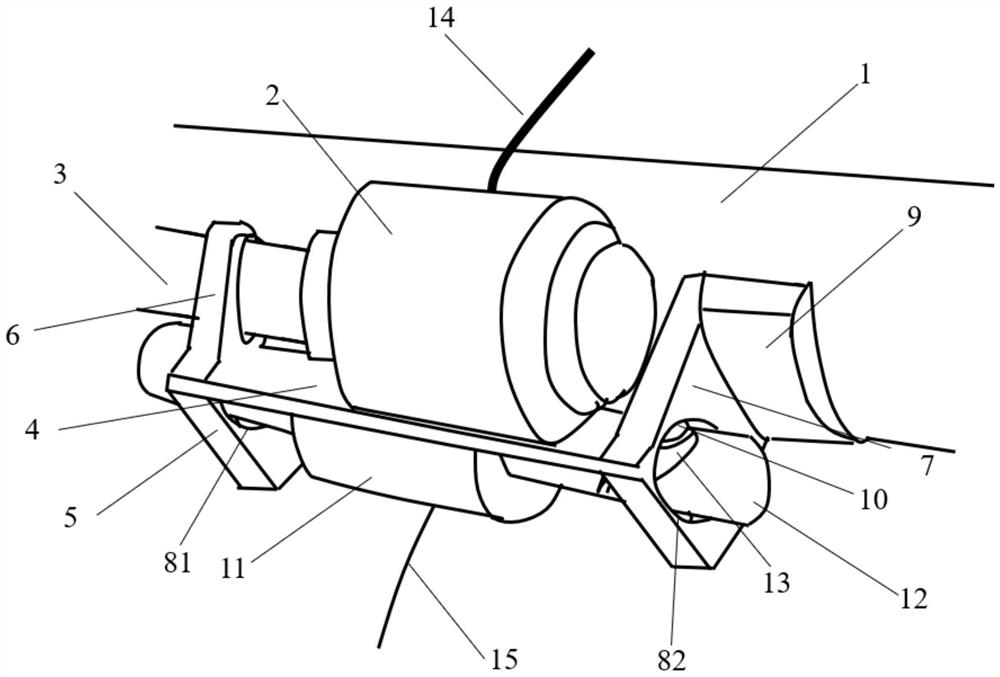

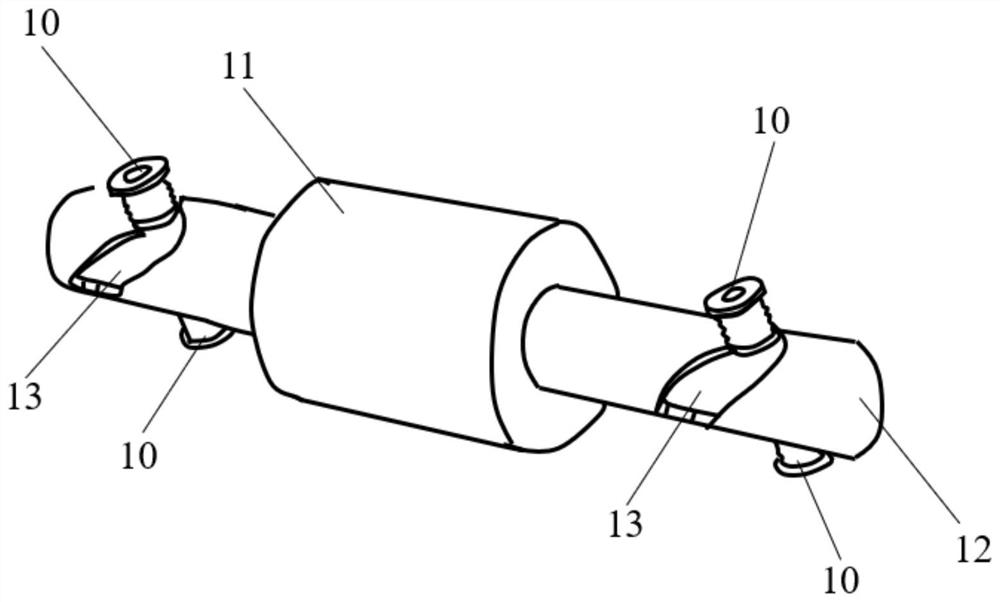

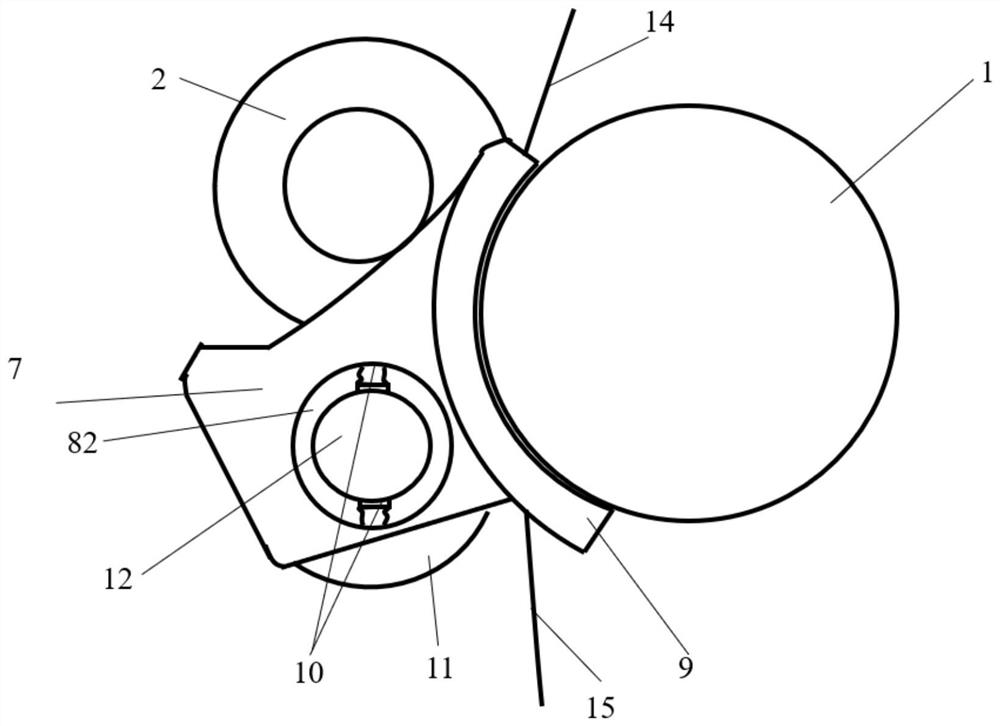

[0032] 800tex pure cotton roving is used to spin 60 British counts of spun yarn. The thickness of the left base frame 5 and the right base frame 7 is 16 mm respectively. The length of the central axis base frame 4 is 150 mm. The central axis base frame 4 and the front roller 1 The gap between them is 3mm, the material of the base frame is plastic, the magnetic adsorption force of the magnetic device 9 is set to 15N, the left circular channel 81 and the right circular channel provided on the left base frame 5 and the right base frame 7 82 has a diameter of 15mm. The reciprocating thread groove 13 at both ends of the reciprocating shaft 12 is a sine wave thread groove. The pitch of the thread groove is about 5mm, the groove depth is 2mm, and the groove width is 3mm. The slider 10 fits inside the reciprocating thread groove and is cylindrical , about 12mm in diameter; cotton fiber strands 14 enter the drafting system of the ring spinning frame, after being drafted by the drafting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com