A method for repairing and strengthening reinforced concrete buildings by sticking steel

A reinforced concrete and construction technology, applied in the field of reinforced concrete, can solve the problems of decreased adhesion tightness, narrow size range, low device usability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

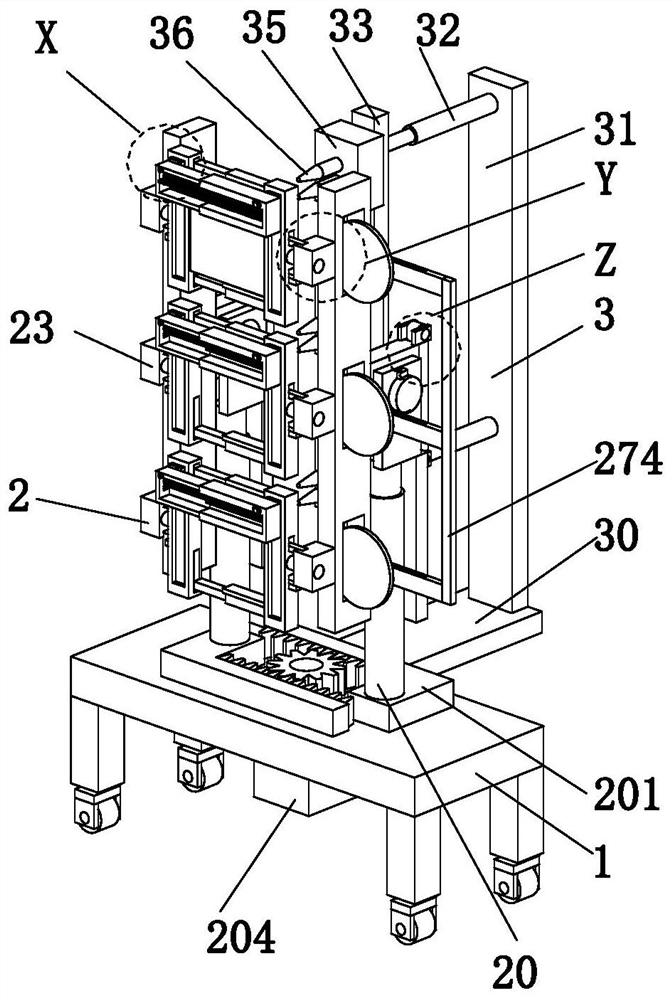

[0042] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention may be implemented in many different ways as predetermined and covered by the claims.

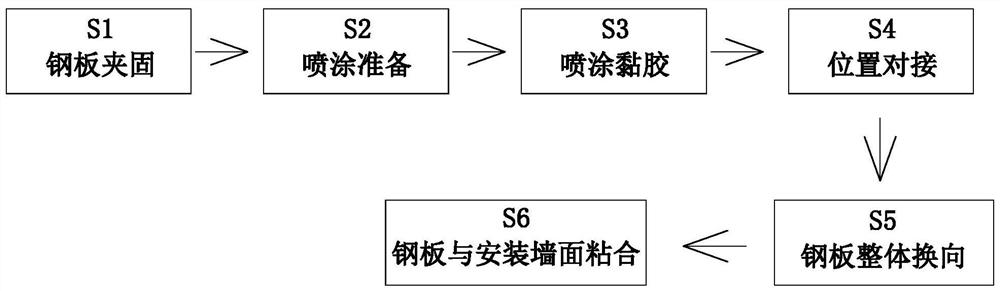

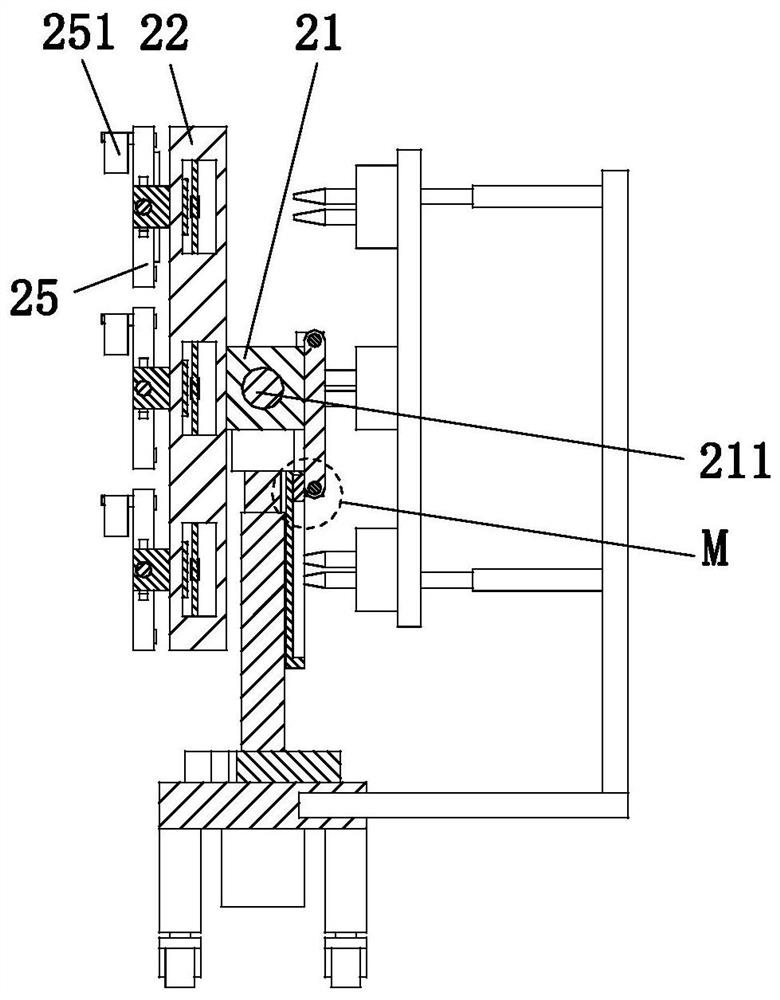

[0043] like Figure 1 to Figure 13 Shown is a reinforced concrete building bonding steel repairing and strengthening method, which uses a reinforced concrete building bonding steel repairing and strengthening device, the reinforced concrete building bonding steel repairing and strengthening device comprises a mobile platform 1, a fixing mechanism 2 and a spraying mechanism 3, using steel bars. The concrete repair and reinforcement method of the concrete building sticky steel repair and reinforcement device is as follows:

[0044] S1. Steel plate clamping: manually place the steel plate between the front and rear vertical plates 25 facing each other, and its glue spraying surface protrudes from the right end face of the vertical plate 25. At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com