Coal mine multifunctional model test mining device and method

A model test, multi-functional technology, applied in driving devices, measuring devices, surface mining and other directions, can solve problems such as difficult monitoring, reduce test reliability, restrict coal mining model test research, etc., to improve mining efficiency, reduce The effect of trial error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

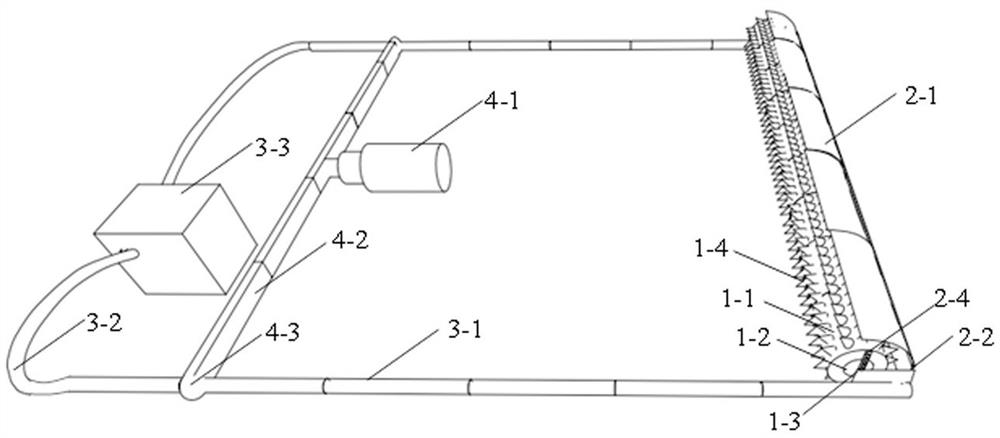

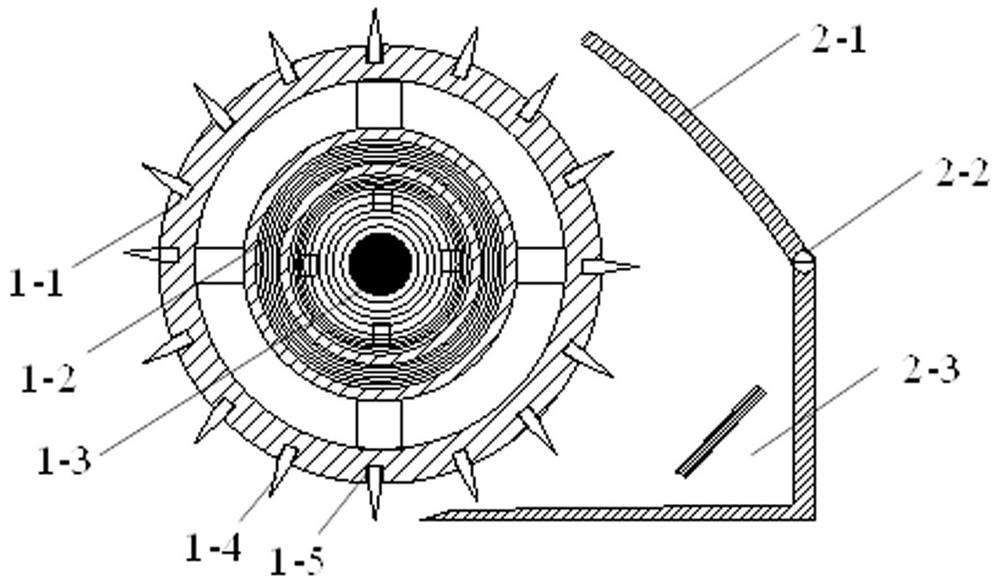

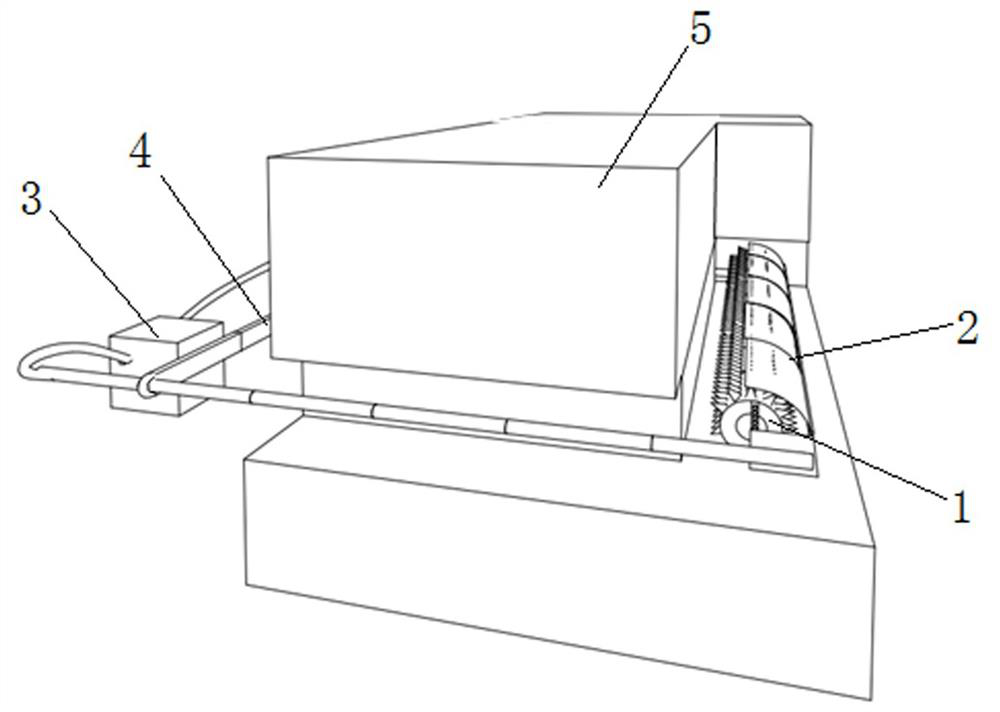

[0041] This embodiment provides a coal mine multifunctional model test mining device, such as figure 1 and Figure 5 As shown, it includes a combined cutting assembly 1, a coal collection protection assembly 2, a powerful coal output assembly 3, a power assembly 4, and a top cutting assembly 6. The combined cutting assembly 1 is installed inside the coal collection protection assembly 2, and the coal collection protection assembly 2 is used for The combined cutting assembly 1 is fixed, and plays the roles of collecting chips and protecting at the same time. The powerful coal output assembly 3 is connected with the coal collection protection assembly 2, and the power assembly 4 is slidingly connected with the powerful coal output assembly 3; the power assembly 4 provides power for the device to ensure that the device can move directionally. When the roof cutting simulation is carried out, the roof cutting assembly 6 is installed on the side of the coal gathering protection ass...

Embodiment 2

[0060] This embodiment provides a multifunctional model test mining method for coal mining, using the mining device described in Embodiment 1, comprising the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com