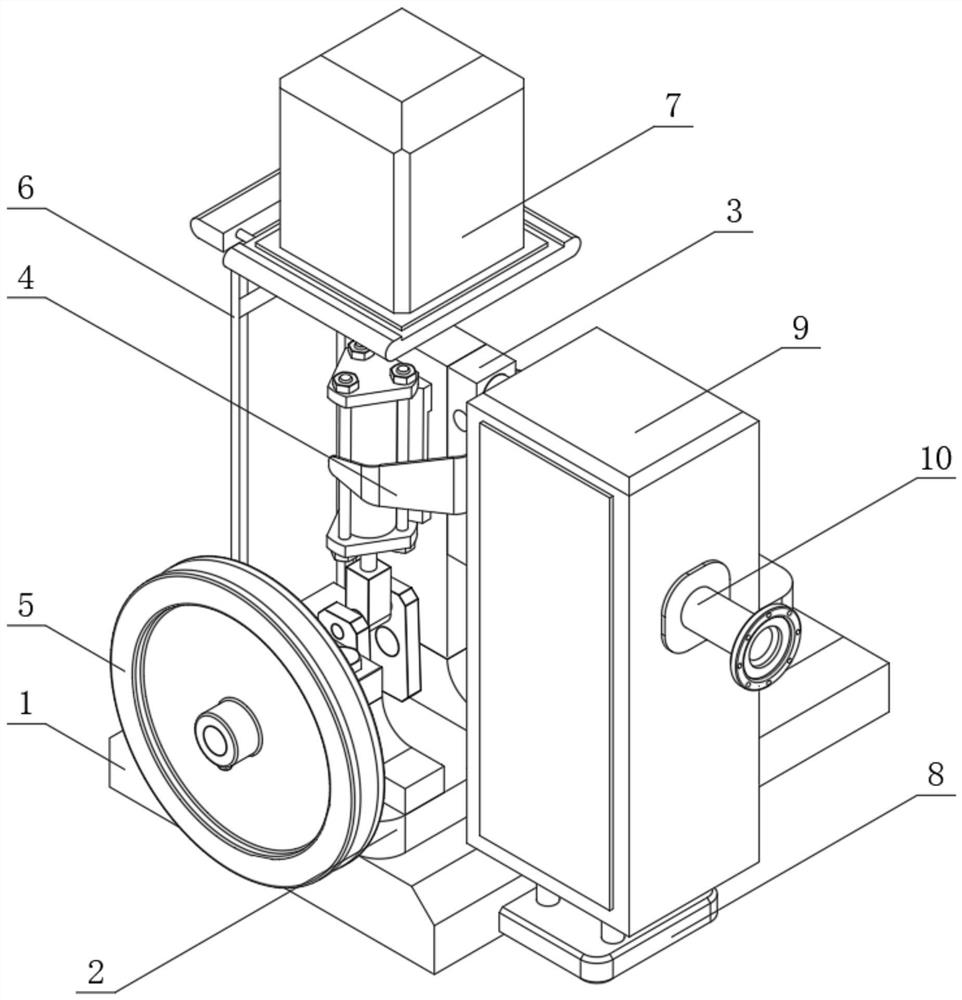

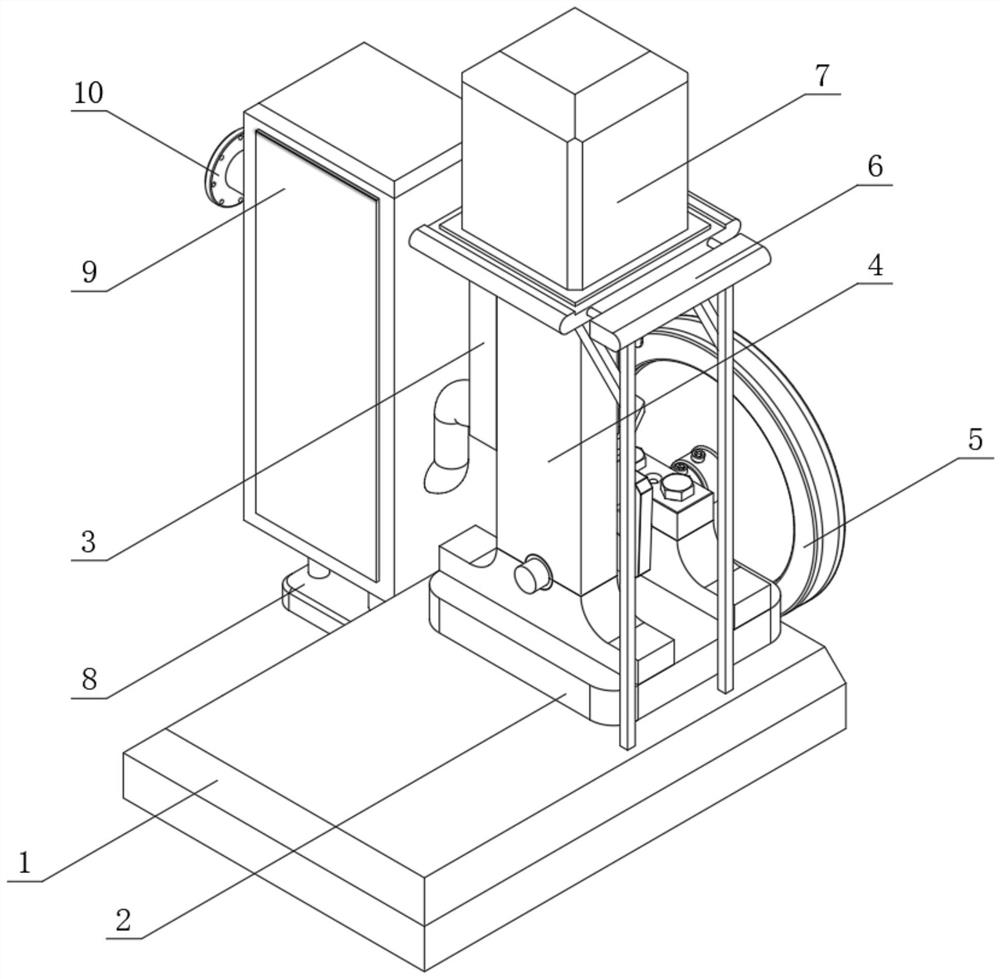

Water drop steam engine

An engine and steam technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems affecting the service life of equipment, high equipment temperature, complex structure, etc., to achieve good heat dissipation effect, improve heat dissipation rate, and good transmission effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

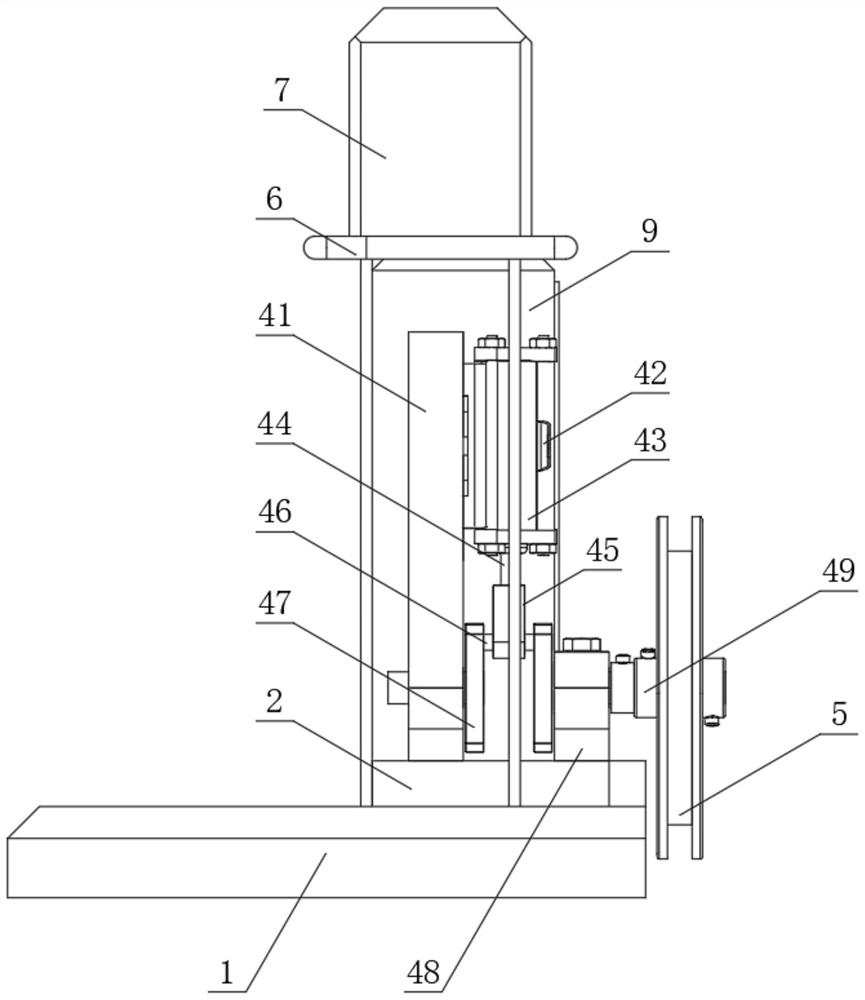

[0022] As an embodiment of the present invention, the supporting assembly 6 includes a supporting top frame 61, a load bearing plate 62, an installation brace 63 and a diagonal brace 64, and the installation brace 63 is fixedly installed on the other side of the top end surface of the anti-skid chassis 1 by welding. On the side, the top end surface of the installation strut 63 is fixedly installed with a support top frame 61 by bolts, and the side end surface of the support top frame 61 is fixedly installed with a load-bearing plate 62, and the bottom end surface of the load-bearing plate 62 is fixedly installed with a diagonal brace 64 by welding. And one end of the bottom of the diagonal brace 64 is fixedly connected with the installation brace 63, and the heat dissipation assembly 7 is installed on the top end surface of the bearing plate 62; at the top of the piston cylinder 43, the top frame can be supported by installing the brace 63 and the diagonal brace 64. 61 and bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com