Dust removal device and mechanism and automatic dust removal method

A technology of automatic dust removal and dust removal device, applied in separation methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems of complicated procedures, waste of raw materials, low work efficiency, etc., achieve compact and portable structure, improve work efficiency, and improve The effect of crystal growth quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

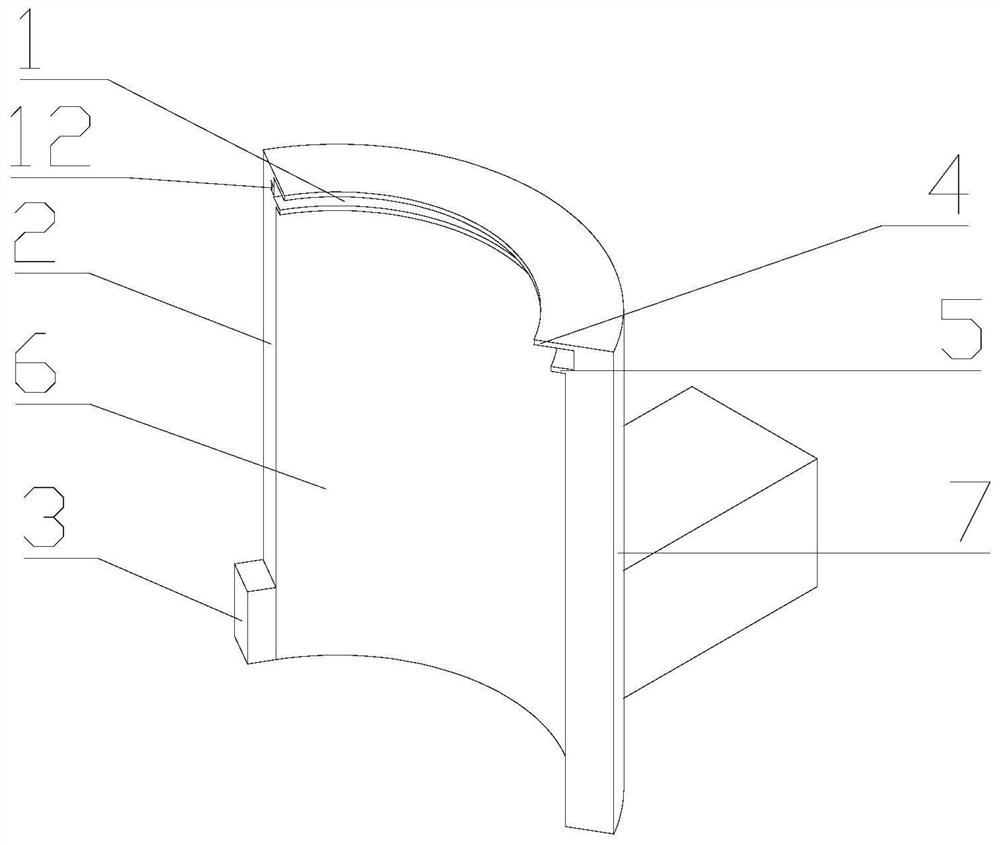

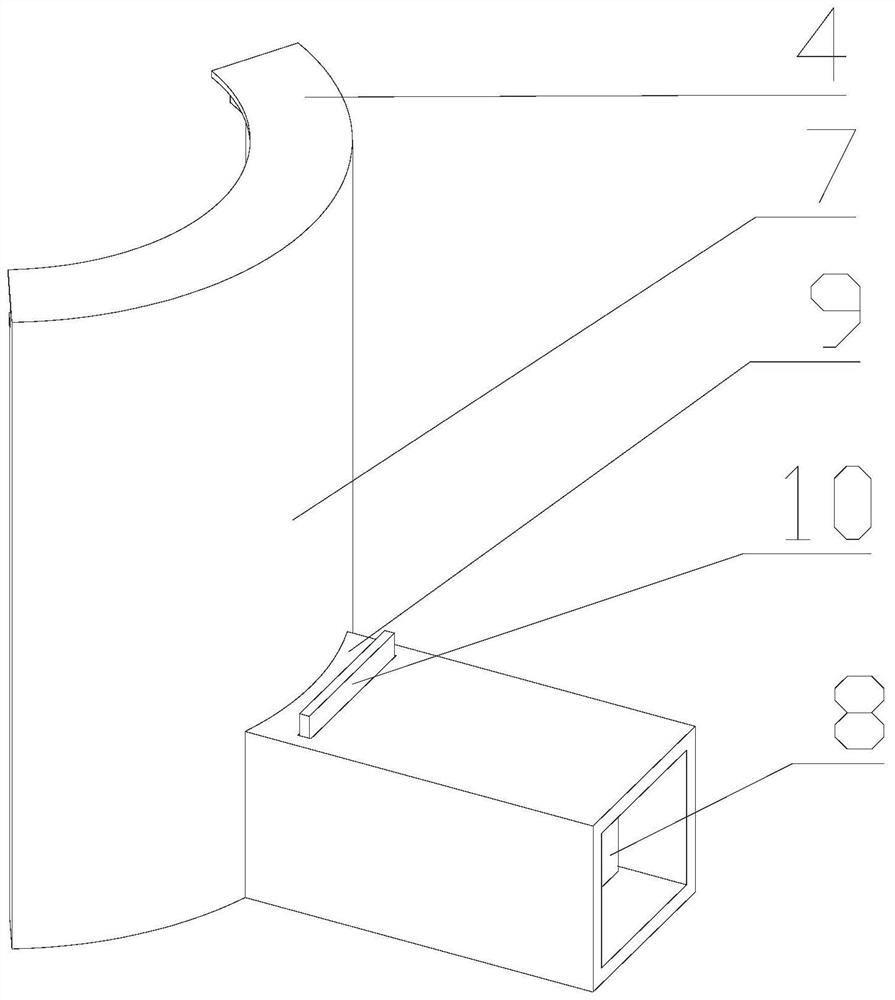

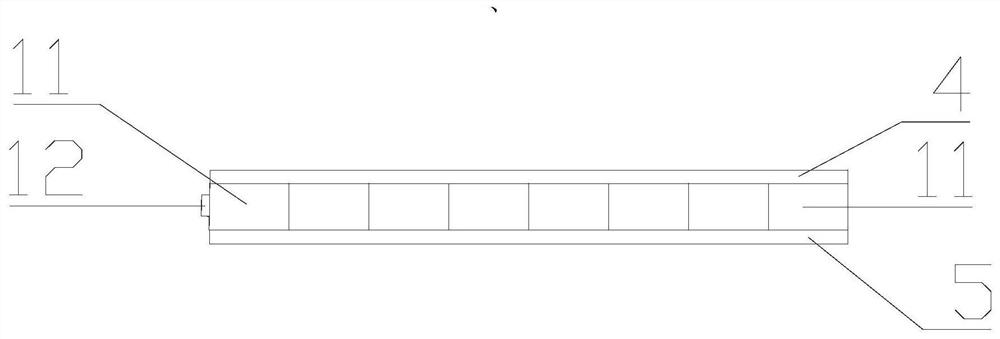

[0055] refer to figure 1 , the embodiment of the present application discloses a dust removal device, the dust removal device includes a housing and an induction unit 3, the housing forms an airflow channel 2 with an air inlet 1, and the airflow channel 2 communicates with the air inlet of the airflow generating unit 8, The part to be dusted is placed in the airflow area formed by the air inlet 1; the sensing unit 3 is connected to the airflow generating unit 8, and the part to be dusted is placed in the sensing area of the sensing unit 3, and the airflow generating unit 8 is activated by the controller to form an airflow along the air inlet 1. , the airflow channel 2, the air inlet and the airflow flowing from the airflow generating unit 8; if the object to be removed is removed from the sensing area of the sensing unit 3, the controller closes the airflow generating unit 8. The air flow generating unit 8 is not a part of the device, it can be connected to the outside of ...

Embodiment 2

[0072] The embodiment of the present application discloses a dust removal method, which includes the following steps: providing powder, a crucible, a housing, an induction unit 3 and an airflow generating unit 8, the housing forms an airflow channel 2 with an air inlet 1, and the airflow Channel 2 communicates with the air inlet of airflow generating unit 8; when the crucible is placed in the sensing area of induction unit 3, the output signal of induction unit 3 controls the start of airflow generating unit 8, forming a Add powder to the crucible to start dust removal; stop adding powder to the crucible, move the crucible out of the sensing area of the sensing unit 3, and the sensing unit 3 outputs a signal to control the airflow generating unit 8 Close, the dust removal is finished.

[0073] This method is realized by using the dust removal device and mechanism of Embodiment 1. The crucible is placed about 5 mm away from the front side wall of the housing. At this time, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com