Backlight semi-finished product assembling jig

A technology for assembling jigs and semi-finished products, applied in optics, nonlinear optics, instruments, etc., can solve the problems of low yield, increased production energy loss, and inability to limit positions exactly the same, so as to improve product yield and reduce capacity loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments provided by the present invention will be specifically described according to the accompanying drawings.

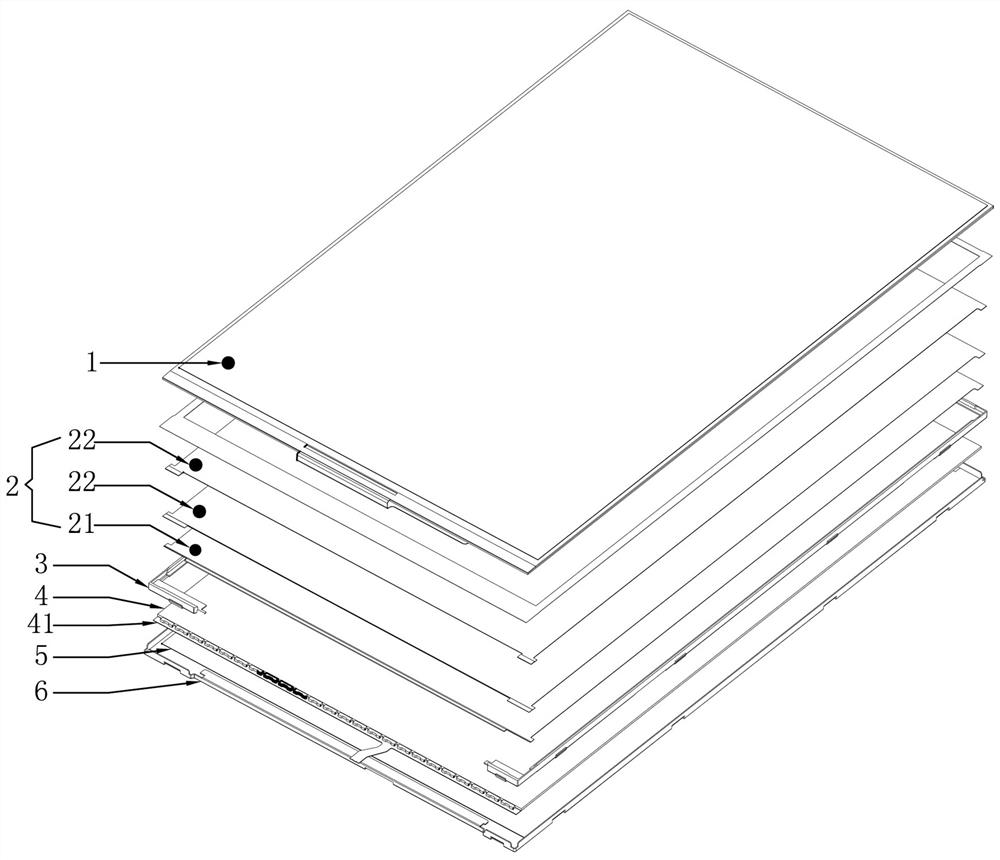

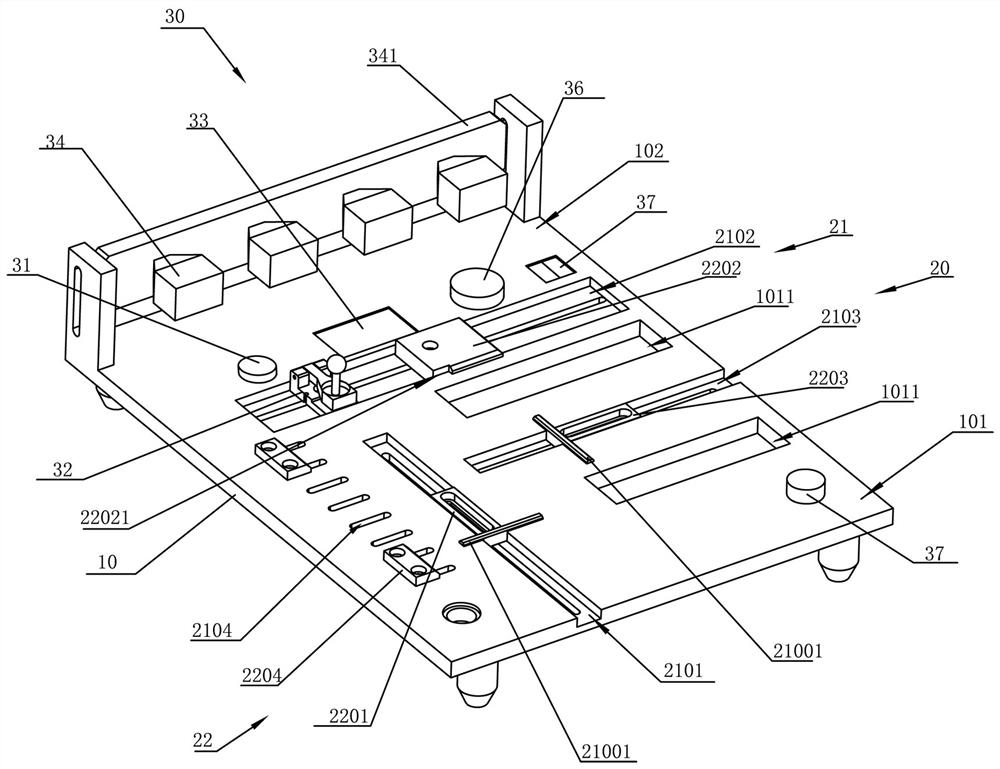

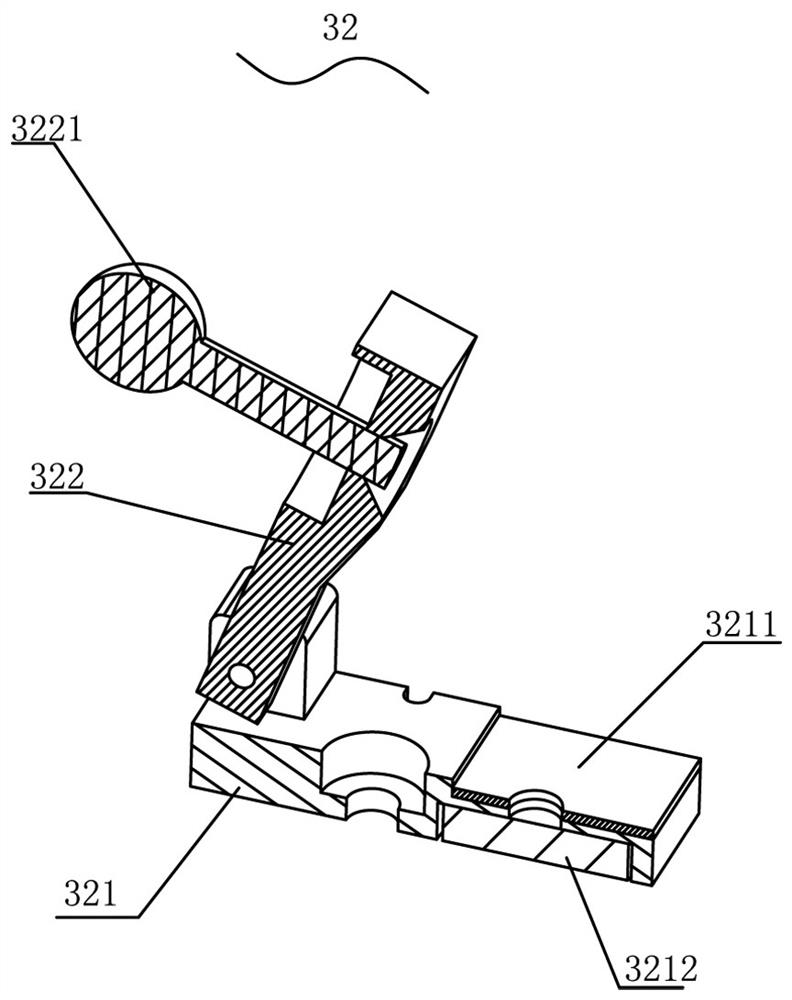

[0021] Figure 2 to Figure 4 , which is a preferred embodiment of a backlight semi-finished assembly jig provided by the present invention. Such as Figure 2 to Figure 4 As shown, the backlight semi-finished assembly fixture includes a fixture seat 10, which is divided into a workbench area 101 and a detection area 102. The workbench area 101 is provided with a positioning assembly 20 for positioning the backlight semi-finished workpiece. The positioning assembly 20 includes a chute 21 arranged in the jig seat, and a sliding seat 22 for positioning the side of the workpiece is matched in the chute; a detection assembly 30 is arranged in the detection area 102, and the detection assembly 30 includes a backlight electrically connected to the workpiece The power supply connection seat 32 and at least one detection lamp 34 that is electrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com