Cpk-based oil refining and chemical engineering device control stability test method

A technology of refining chemical industry and inspection method, which is applied in the field of inspection of the stability of production control parameters in refining and chemical industry, can solve the problems of different, inability to make clear judgments on operation stability, and inability to quantify and stabilize, so as to eliminate the influence of human factors, True and comprehensive reliability and stability, eliminating the effect of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

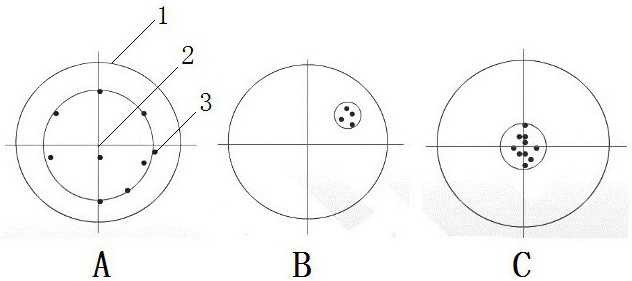

[0030] The invention discloses a Cpk-based method for testing the control stability of a refinery and chemical plant, comprising the following steps:

[0031] Step 1: Determine several key operating indicators of the process, set as xi; where i≥1 and is an integer;

[0032] Step 2: Assume that there are n teams or time periods for process operations, where n≥1 and an integer; randomly extract operation data from different teams or time periods, and extract at least 25 operation data for each key operation indicator; (the more the better , DCS system or real-time database to automatically collect data is the best);

[0033] Step 3: Record the operating data of these key control indicators respectively, denoted as xi, j, n; where i≥1 and is an integer; j=1, 2, 3,...k; k≥25 and is an integer; n ≥1 and an integer;

[0034] Step 4: Perform a normality test on the operating data of each key indicator. If the data obeys the normal distribution, go directly to the fifth step; otherw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com