Fine powder resource evaluation method, device and equipment and storage medium

A technology of resource evaluation and refined powder, which is applied in the field of mineral quality management, can solve problems such as the complexity of the calculation process, and achieve the effect of simplifying the evaluation process and reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

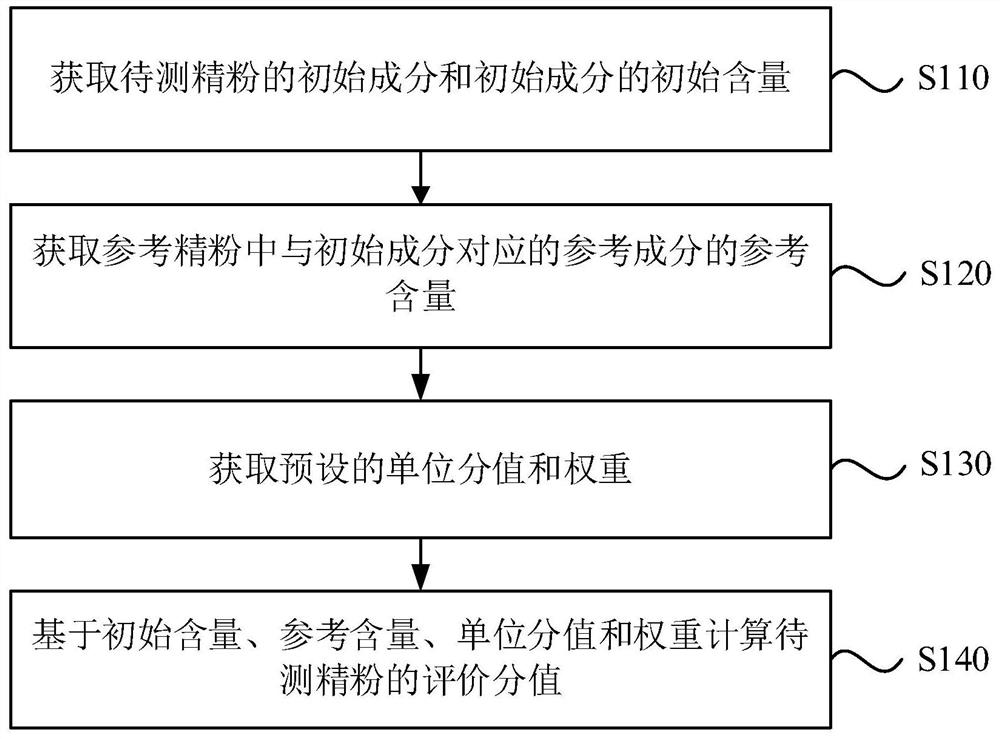

[0056] figure 1 It is a flow chart of the resource evaluation method for fine powder resources provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation of comprehensive quality evaluation of mineral fine powder resources. This method can be executed by a device for evaluating mineral fine powder resources. The device can Realized by software and / or hardware, it can be configured in computer equipment with relatively scarce resources. The computer equipment can be mobile terminals such as mobile phones, tablet computers, wearable devices (such as smart watches, smart glasses, etc.), or, The computer device may be a non-mobile terminal such as a smart TV. The method specifically includes the following steps:

[0057] Step 110, obtaining the initial components of the fine powder to be tested and the initial content of the initial components.

[0058] In the embodiment of the present invention, the ore powder obtained through crushing, gr...

Embodiment 2

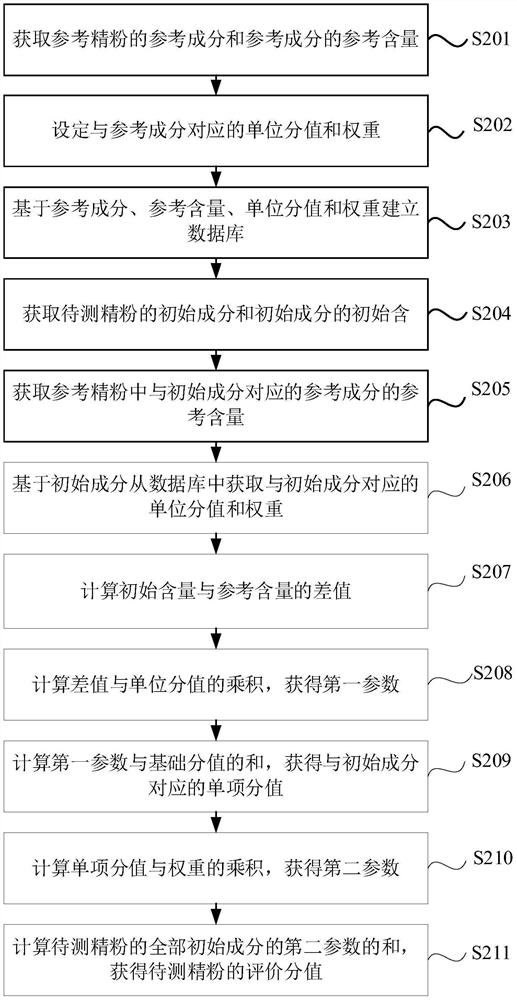

[0070] figure 2 It is a flow chart of a fine powder resource evaluation method provided by Embodiment 2 of the present invention. This embodiment further refines the fine powder evaluation and calculation process on the basis of the foregoing embodiments. The method specifically includes the following steps:

[0071] Step 201. Obtain the reference components of the reference fine powder and the reference content of the reference components.

[0072] In the specific implementation process, it is necessary to select the reference fine powder as the reference object, and determine the reference composition of the reference fine powder and the reference content corresponding to the reference composition. Among them, the reference content of the reference ingredient mainly refers to the mass fraction proportion of the reference ingredient in the unit weight of fine powder, that is, the ratio of the mass of a single ingredient in the reference ingredient to the total mass.

[007...

Embodiment 3

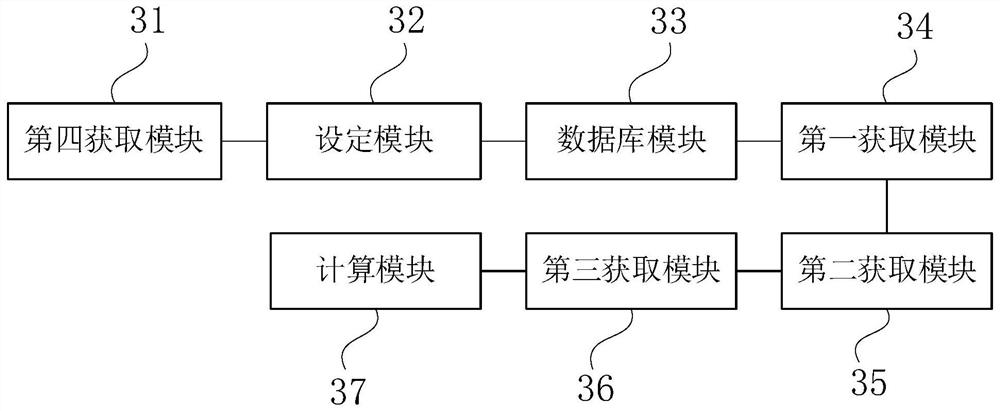

[0122] image 3 It is a schematic structural diagram of a fine powder resource evaluation device provided in Embodiment 3 of the present invention, and the device may specifically include a fourth acquisition module 31, a setting module 32, a database module 33, a first acquisition module 34, and a second acquisition module 35 , a third acquisition module 36 and a calculation module 37 .

[0123] The fourth obtaining module 31 is used to obtain the reference composition of the reference fine powder and the reference content of the reference composition;

[0124] Setting module 32, for setting the unit score and weight corresponding to the reference component;

[0125] The database module 33 is used for establishing a database based on reference components, reference contents, unit scores and weights.

[0126] The first obtaining module 34 is used to obtain the initial composition of the fine powder to be tested and the initial content of the initial composition;

[0127] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com