Shifting fork magnetic assembly

A technology of magnetic components and magnets, applied in the direction of magnetic objects, magnets, permanent magnets, etc., can solve problems such as affecting the overall operation, affecting the stability of magnet clamping, and inaccurate magnetic field signals, reducing the probability of demagnetization and improving connection stability. Sex, the effect of reducing the overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

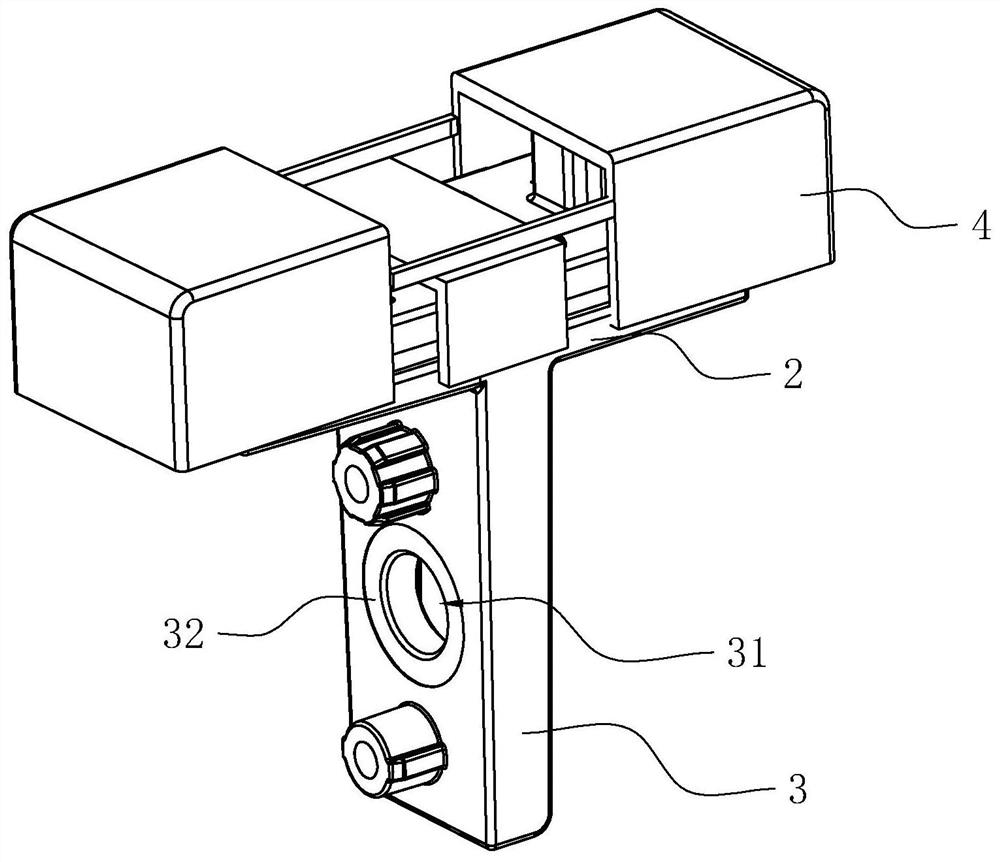

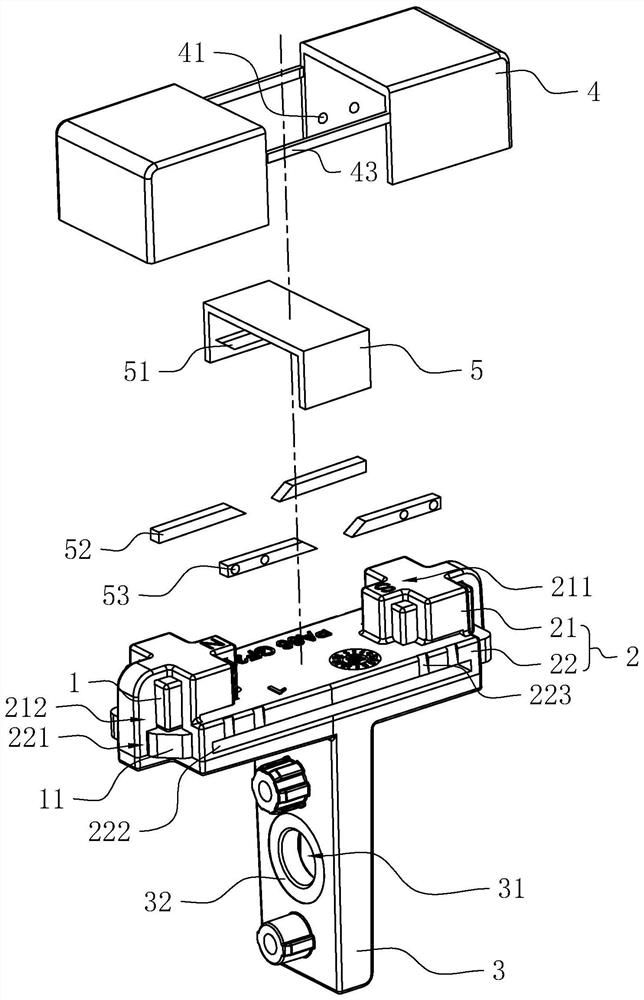

[0041] refer to figure 1 and figure 2 , the shift fork magnetic assembly includes a base body and a magnet 1, and the roughly T-shaped base body includes a plastic coating part 2 and a mounting part 3, and the plastic coating part 2 and the mounting part 3 are integrally formed, all of which can be made of nylon, but not limited to Nylon material; the overmolding part 2 includes two first overmolding bodies 21 and a second overmolding body 22, the first overmolding body 21 is located on the side of the second overmolding body 22 away from the mounting part 3, each first A magnet 1 is overmolded in the overmolding body 21 , and a heat-conducting yoke plate 11 is overmolded in the second overmolding body 22 , and one side of the supporting heat-conducting yoke plate 11 abuts against one side of the magnet 1 .

[0042] The overmolding part 2 is provided with two marking areas 211 marked with cathode and anode respectively, and the two marking areas 211 correspond to two magnets...

Embodiment 2

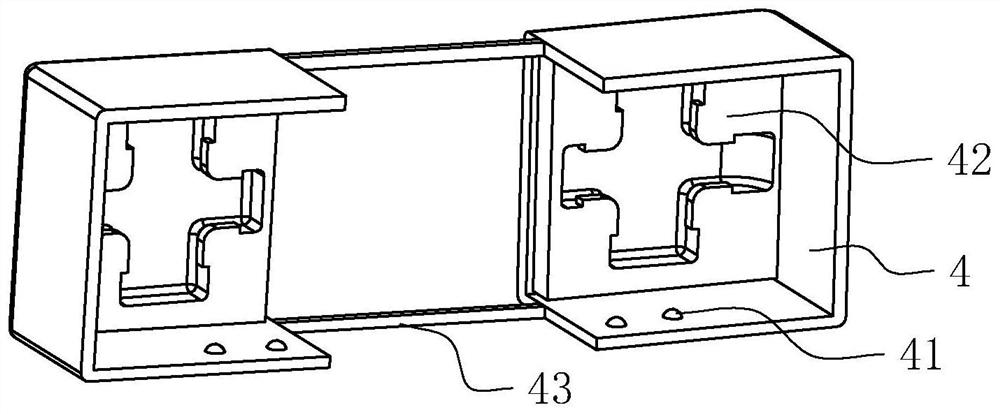

[0054] refer to Figure 4 The difference between this embodiment and Embodiment 1 is that the reserved positioning groove 212 left due to the positioning of the magnet 1 in the mold is located on the periphery of the first overmolding body 21, and the first overmolding body 21 is in the shape of X-shaped cross-wrapped plastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com