Dust removal device for factory automation system

A technology of factory automation and dust removal device, which is applied in combination devices, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of reduced dust removal effect of dust removal equipment, reduced filter effect of filter screen, etc. longevity, wear reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

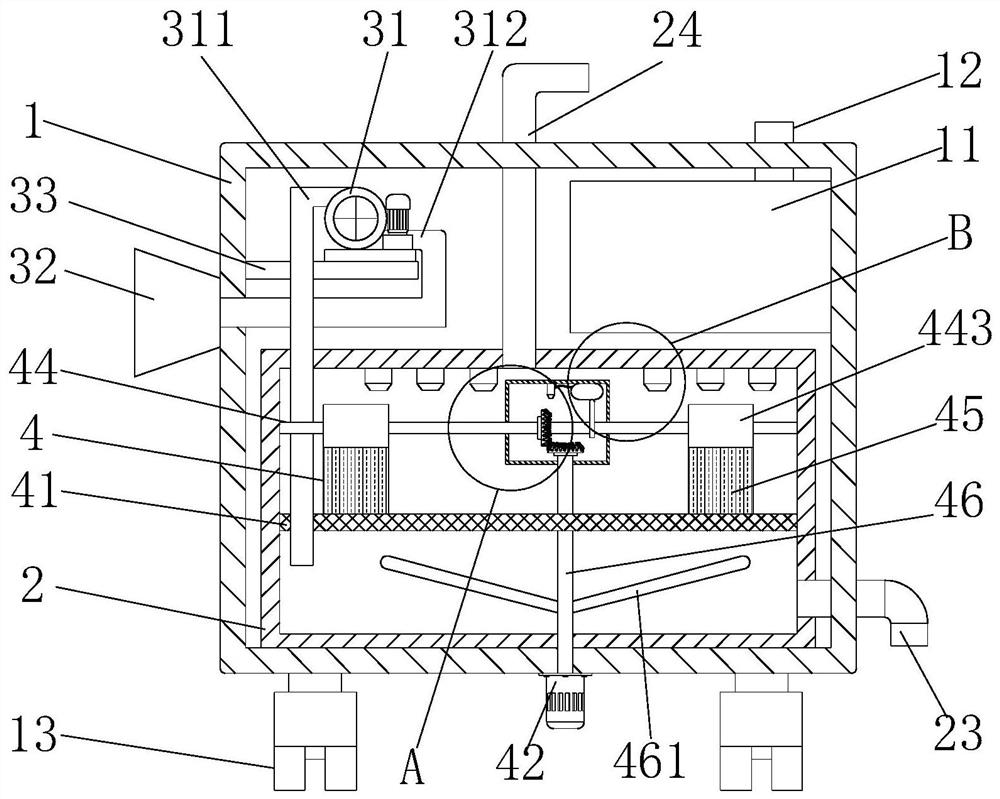

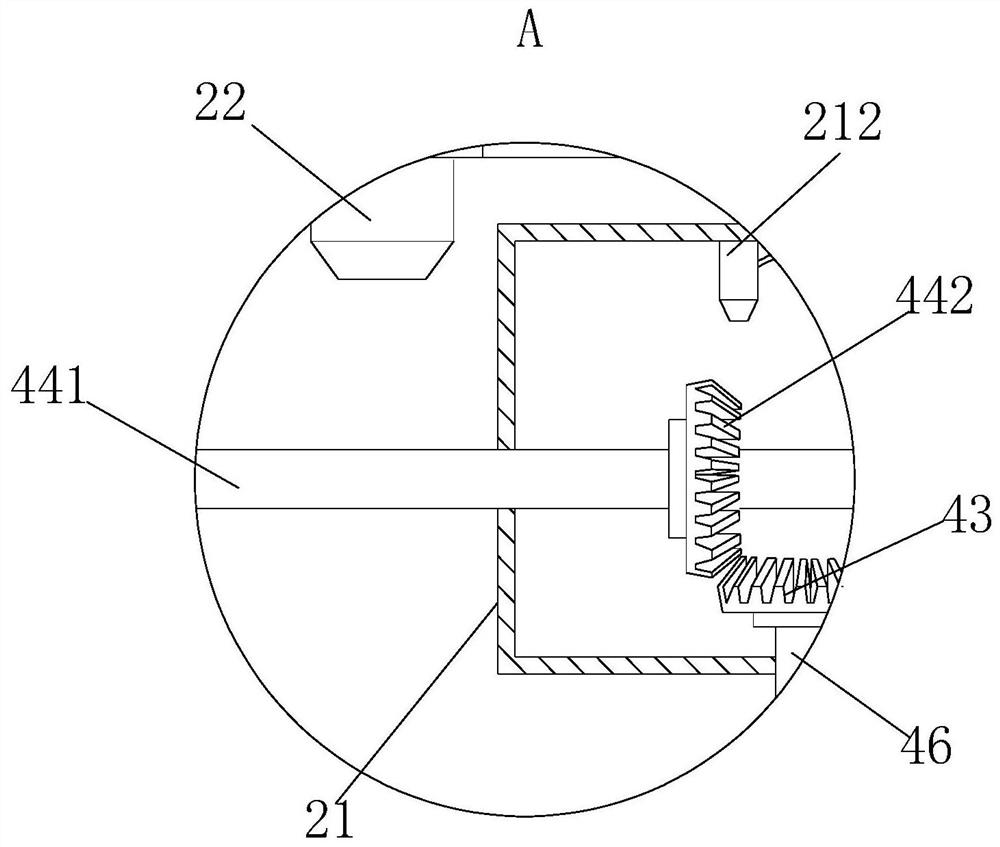

[0022]As an embodiment of the present invention, the transmission mechanism 44 includes a screw rod 441 and a second bevel gear 442; the screw rod 441 is rotatably connected to the inner wall of the dust removal box 2, and a pair of sliders are sleeved on the outer wall thereof 443; the slider 443 and the screw rod 441 are connected by a ball screw nut pair; the cleaning brush 45 is affixed to the bottom of the slider 443; the second bevel gear 442 is affixed to the outer wall of the screw rod 441, and The first bevel gear 43 meshes; during work, when the filter screen 41 is cleaned, the motor 42 is started, and the motor 42 drives the rotating shaft 46 and the first bevel gear 43 to rotate, and the first bevel gear 43 meshes with the second bevel gear 442 , thereby driving the second bevel gear 442 and the screw rod 441 to rotate, a pair of sliders 443 are set on the outer wall of the screw rod 441, and the threads on the outer wall of the screw rod 441 are symmetrical threads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com