Bone wax mixing device for hemostasis in neurosurgery operation

A technology of neurosurgery and mixing devices, which is applied to mixers with rotating stirring devices, mixers, transportation and packaging, etc., which can solve the problems of reduced operation volume, large operation volume, uneven application of beeswax and Vaseline, etc., and achieve increased The effect of kneading mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

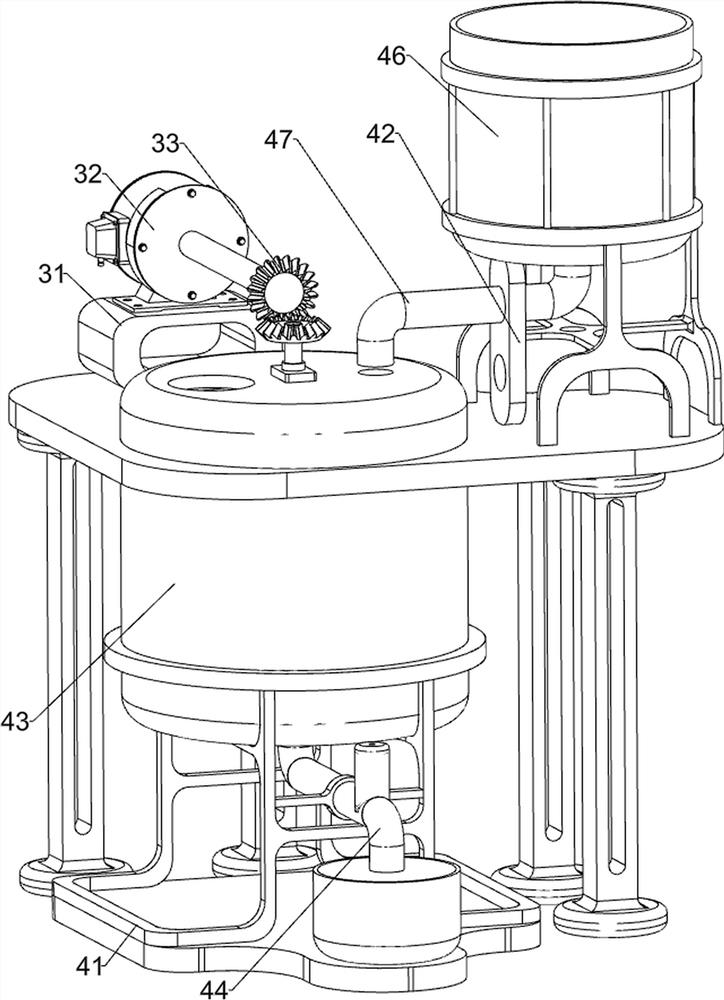

[0049] A bone wax mixing device for hemostasis in neurosurgery, such as figure 1 As shown, it includes a bottom plate 1, a mounting frame 2, a mixing mechanism 3 and a raw material placement mechanism 4, the top of the bottom plate 1 is connected with a mounting frame 2, the rear side of the top of the mounting frame 2 is provided with a mixing mechanism 3, and the mounting frame 2 is provided with Raw material placement mechanism4.

[0050] The staff can place the vaseline and beeswax in the raw material placement mechanism 4, start the raw material placement mechanism 4 to heat the vaseline and beeswax, and start the mixing and stirring mechanism 3 to stir the heated raw materials. After all the stirring is completed, stop the mixing and stirring mechanism 3 operation.

Embodiment 2

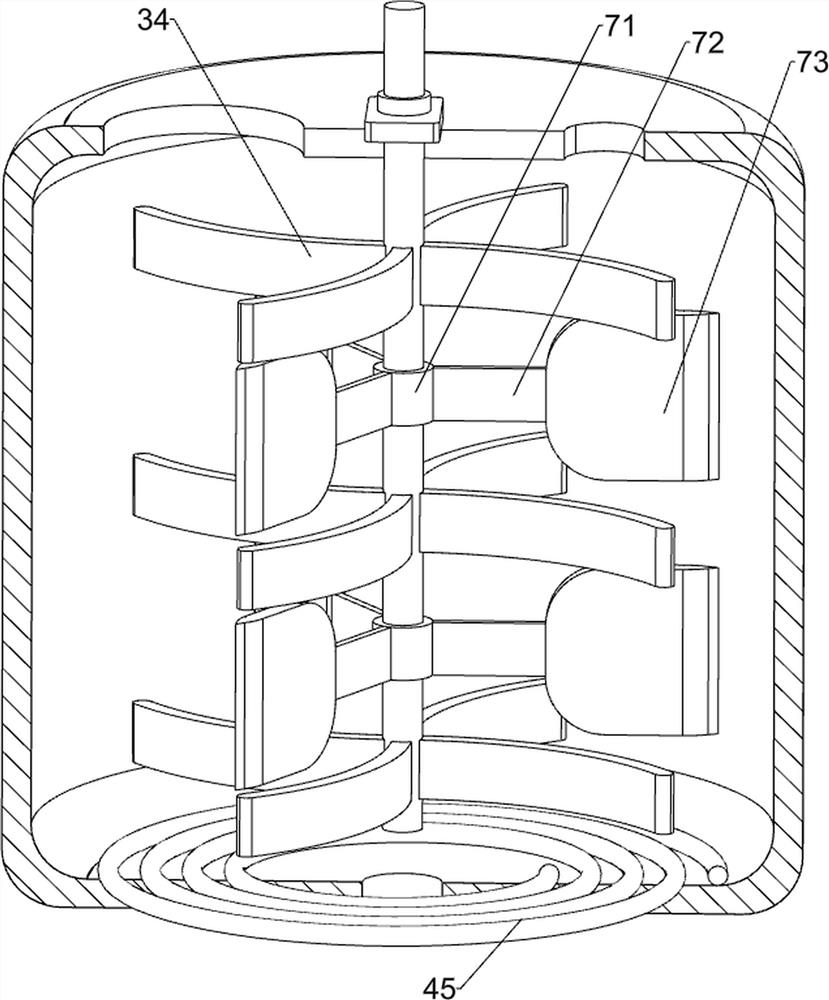

[0052] On the basis of Example 1, such as figure 2 and Figure 7 As shown, the raw material placement mechanism 4 includes a placement frame 41, a support frame 42, a stirring chamber 43, a finished product outflow pipeline 44, a raw material heating pipe 45, a beeswax placement tank 46, a beeswax outflow pipeline 47 and a beeswax heating pipe 48. There is a placement rack 41, and the placement rack 41 is provided with a stirring chamber 43, the stirring chamber 43 passes through the mounting frame 2, the bottom of the inner wall of the stirring chamber 43 is provided with a raw material heating pipe 45, the bottom of the stirring chamber 43 is connected with a finished product outflow pipeline 44, and the mounting frame 2 The right side of the top is provided with a support frame 42, the support frame 42 is provided with a beeswax placement tank 46, the bottom of the beeswax placement tank 46 is connected with a beeswax outflow pipeline 47, and the beeswax outflow pipeline 4...

Embodiment 3

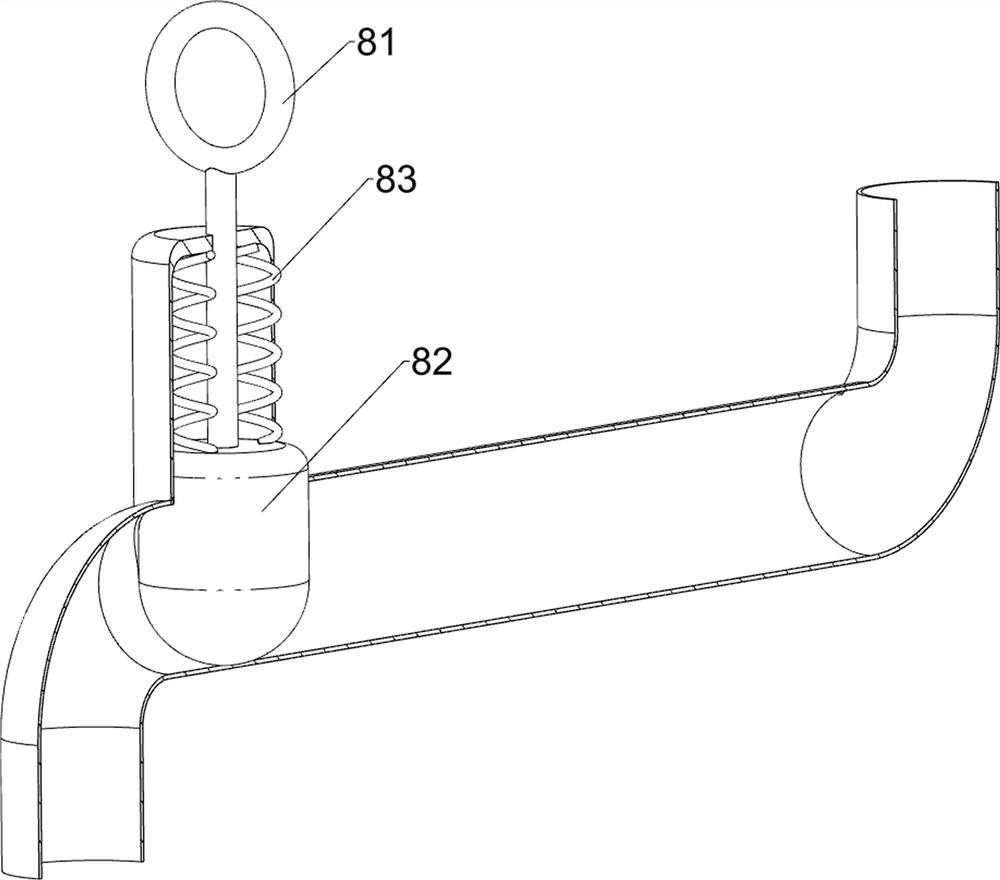

[0056] On the basis of Example 2, such as Figure 3 to Figure 8 As shown, beeswax stirring mechanism 5 is also included, and beeswax stirring mechanism 5 includes support bracket 51, belt pulley assembly 52, second bevel gear set 53, beeswax stirring blade 54, beeswax filter screen 55 and anti-beeswax clogging stirring rod 56, supporting The top of the frame 42 is connected with a support bracket 51, and the beeswax storage tank 46 bottom inner wall is connected with a beeswax filter screen 55, and the beeswax filter screen 55 is connected with an anti-beeswax clogging stirring rod 56, and the anti-beeswax clogging stirring rod 56 is on the top of the rotating shaft. A plurality of beeswax stirring blades 54 are connected, and a second bevel gear set 53 is connected between the top of the rotating shaft of the anti-beeswax clogging stirring rod 56 and the top of the support bracket 51, and the rear side rotating shaft of the second bevel gear set 53 is connected to the servomot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com