Magnetic powder mixing device

A material mixing device and magnetic powder technology, applied in mixers, transportation and packaging, shaking/oscillating/vibrating mixers, etc., can solve the problems of easy accumulation in the material tank, affecting the mixing effect, and inconvenient cleaning of the material tank, etc., to achieve Improve the use effect, improve the stirring effect, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

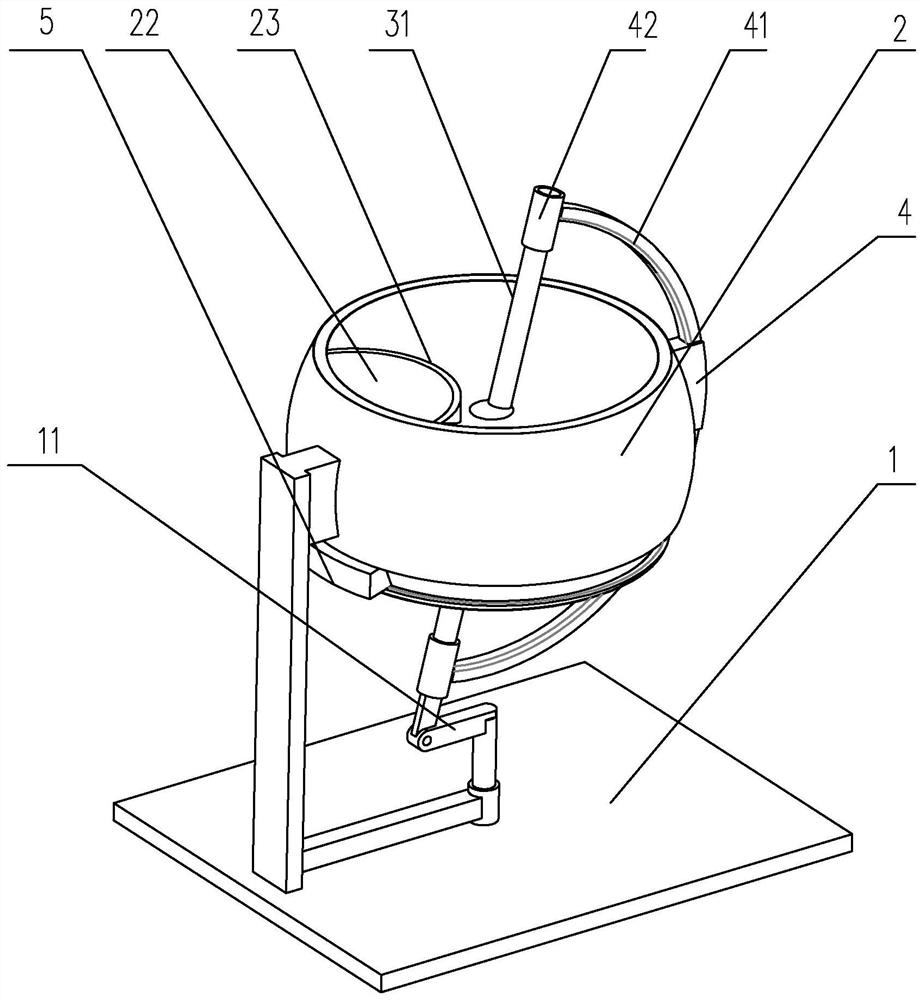

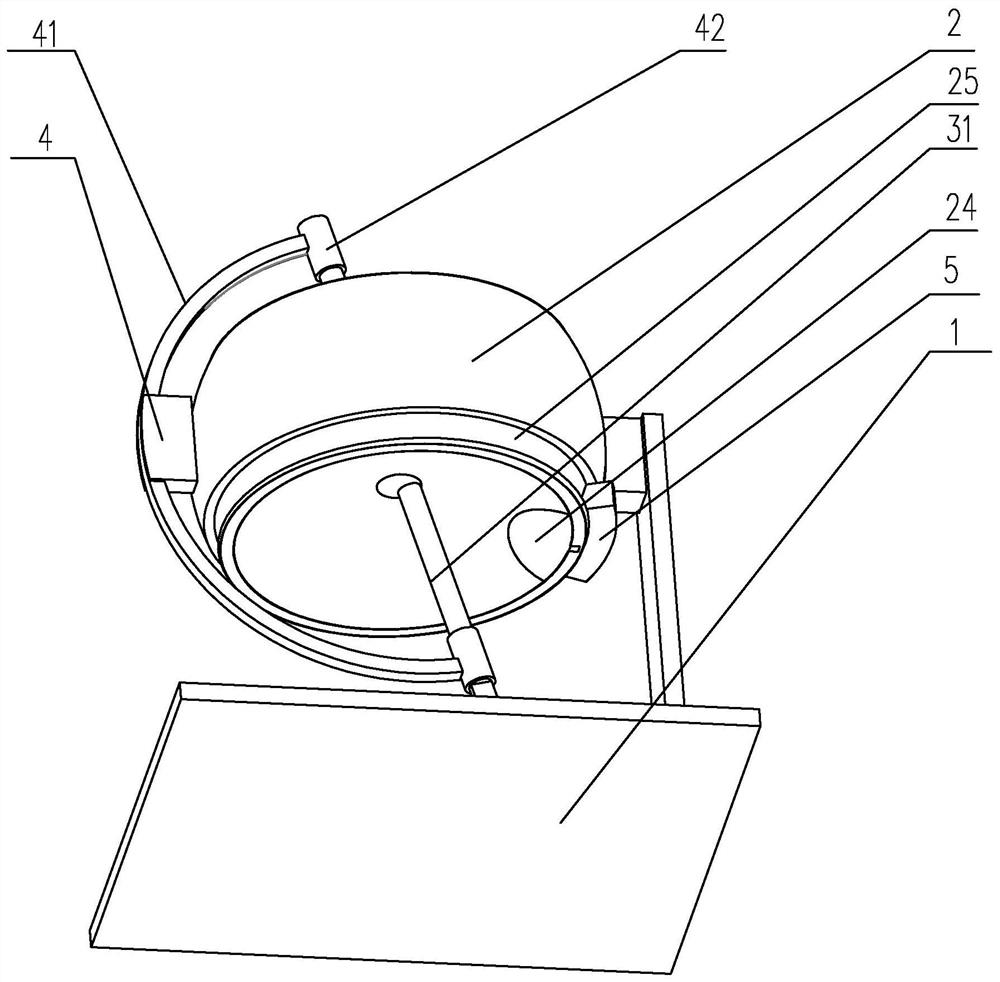

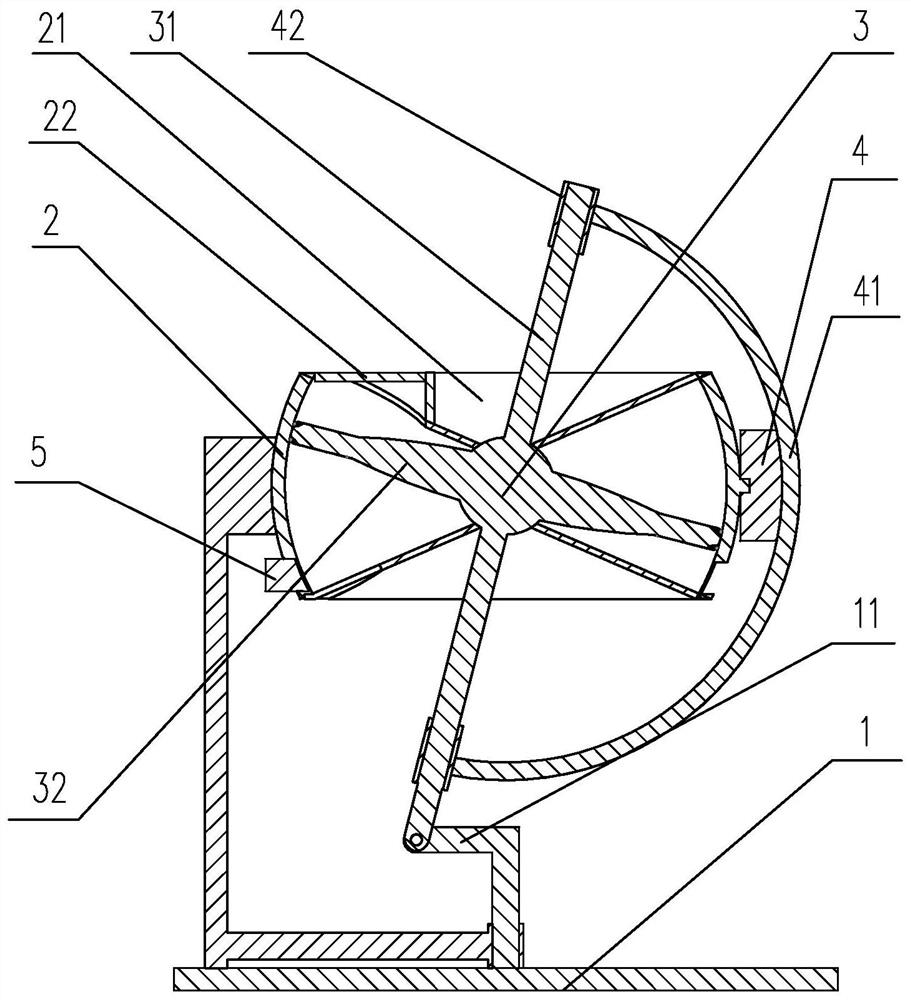

[0024] Examples of the magnetic powder mixing device of the present invention are Figure 1 to Figure 4 Shown: includes a frame body 1, the frame body 1 is provided with a stirring tank 2, the upper and lower ends of the stirring tank 2 are respectively formed with arc-shaped concave cavities 21, and the stirring tank 2 is located between the two arc-shaped concave cavities 21 There is a connection ball 3 between them, and the connection ball 3 is respectively connected to the two arc-shaped concave cavities 21. The connection ball 3 is partially exposed outside the stirring tank 2, and the connection ball 3 is exposed to the stirring tank. 2, a transmission rod 31 is extended on the outer part, and the transmission rod 31 is arranged obliquely. The frame body 1 is provided with a swing rod 11 and a driving member for driving the swing rod 11 to rotate. One end of the swing rod 11 is connected to the drive The output end of the piece is connected, and the other end is rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com