Coating tanks for lost foam casting

A technology of lost foam casting and coating tank, which is applied in casting molding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of inconvenient operation of coating stirring, equalization, and can not guarantee coating concentration, and achieves good cleaning effect, uniform concentration, The effect of accelerated flushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

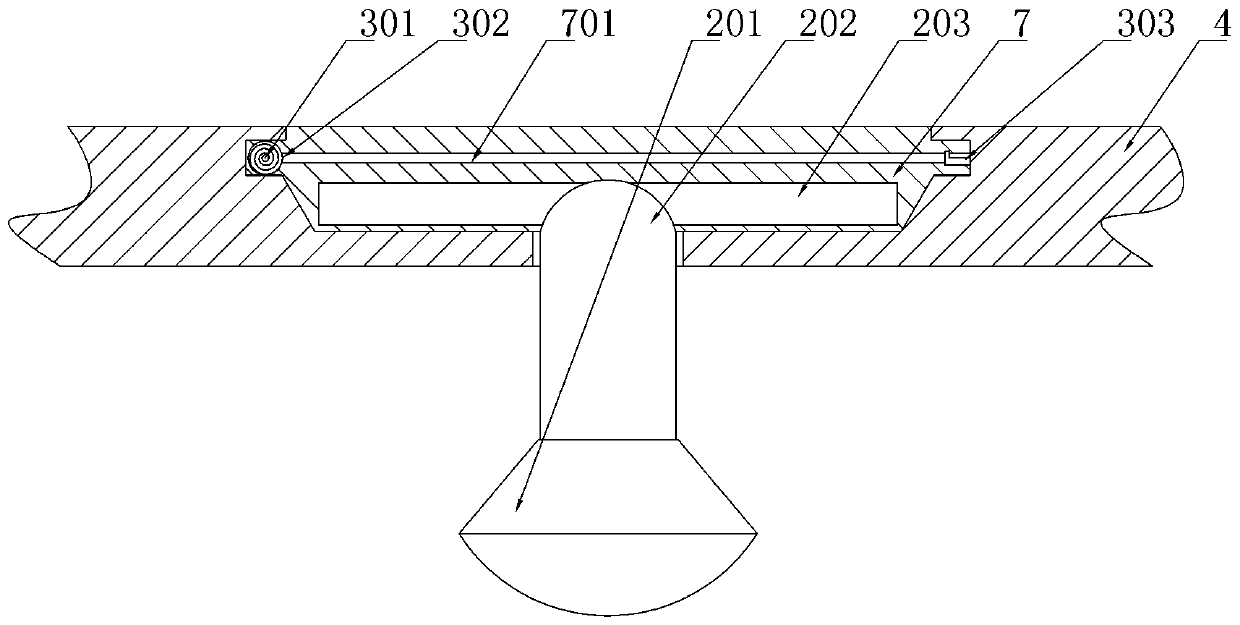

[0012] The reference signs in the drawings of the description include: bottom plate 4 , counterbore 7 , stirring motor 201 , stirring shaft 202 , stirring paddle 203 , movable door 301 , reel 302 , and slideway 701 .

[0013] as attached figure 1 Shown: the coating tank used for lost foam casting, the coating tank is a cuboid structure, the bottom of the four corners is provided with feet, the inside of the coating tank is provided with a bottom plate 4, and the center of the bottom plate 4 is provided with a partition for blocking the sink hole 7 The lower part of the partition device is equipped with a stirring device; the upper part of the outer tank wall of the paint tank is symmetrically provided with a chute, and the chute is slidably connected with a fence. The fence is used for the temporary placement of the pattern. When the pattern is painted in the paint tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com