Artificial intelligence sand screening device achieving automatic adjustment

An artificial intelligence and automatic adjustment technology, applied in the direction of sieve, solid separation, electromagnetic audible signal, etc., can solve the problems of increasing the work intensity of the staff, unable to control the vibration frequency of the sieve plate, affecting the sand screening efficiency, etc. The effect of dividing efficiency, reducing energy consumption and preventing a large amount of accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Example 1

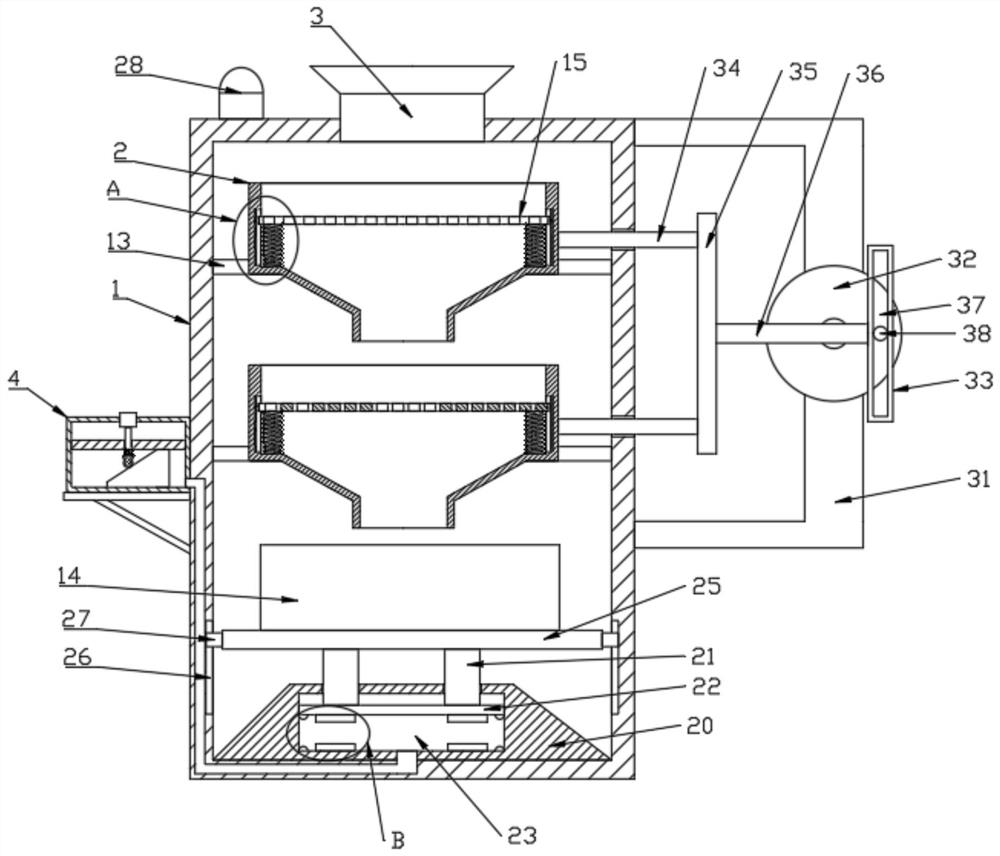

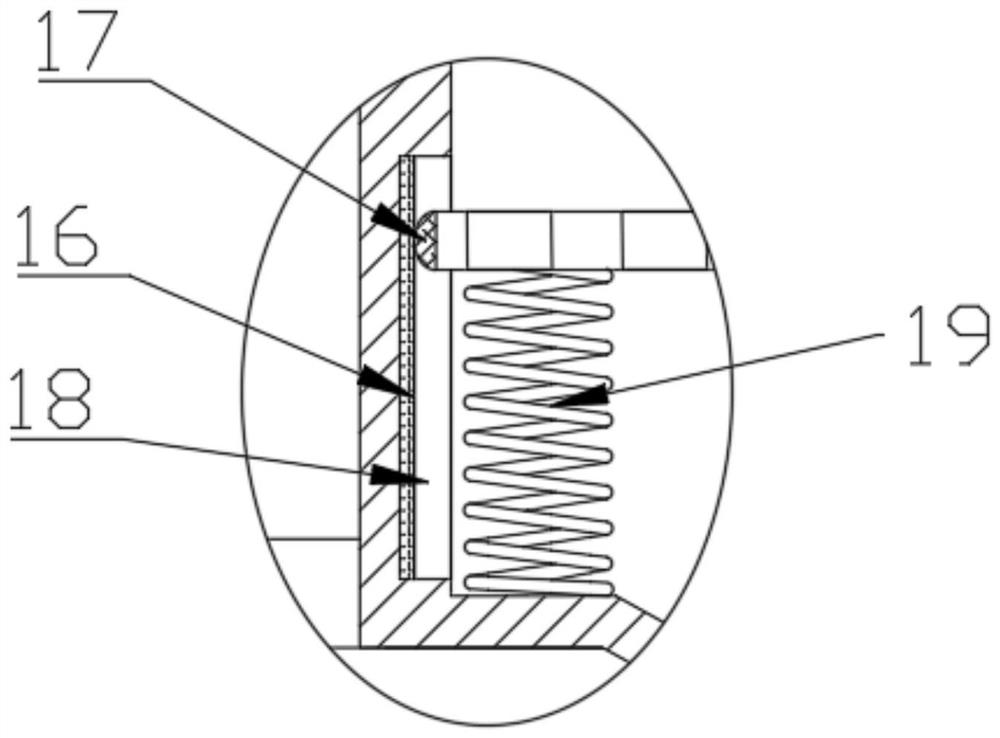

[0026] see Figure 1-6 , a self-adjusting sand screening device for artificial intelligence, including a box 1, two sieve boxes 2 and a drive mechanism for driving the two sieve boxes 2 to and fro, the top surface of the box 1 is provided with a feed Passage 3, the outer wall of the box body 1 is fixed with a bracket, the bracket is fixed with a casing 4, and the casing 4 is provided with a control switch 5 electrically connected to the driving mechanism, and the two sieve boxes 2 One-to-one corresponding sliding connection in the two-layer chute 13, and an induction mechanism for controlling the operation speed of the drive mechanism is provided in the screen box 2. The induction mechanism includes a sieve plate 15, a variable resistance sheet 16 and a conductive block 17. Both sides of the inner wall of the sieve box 2 are symmetrically provided with a first limiting groove 18, the variable resistor 16 is fixed in the first limiting groove 18, and the sie...

Example Embodiment

[0029] Example 2

[0030] This embodiment expands the functions on the basis of Embodiment 1, specifically:

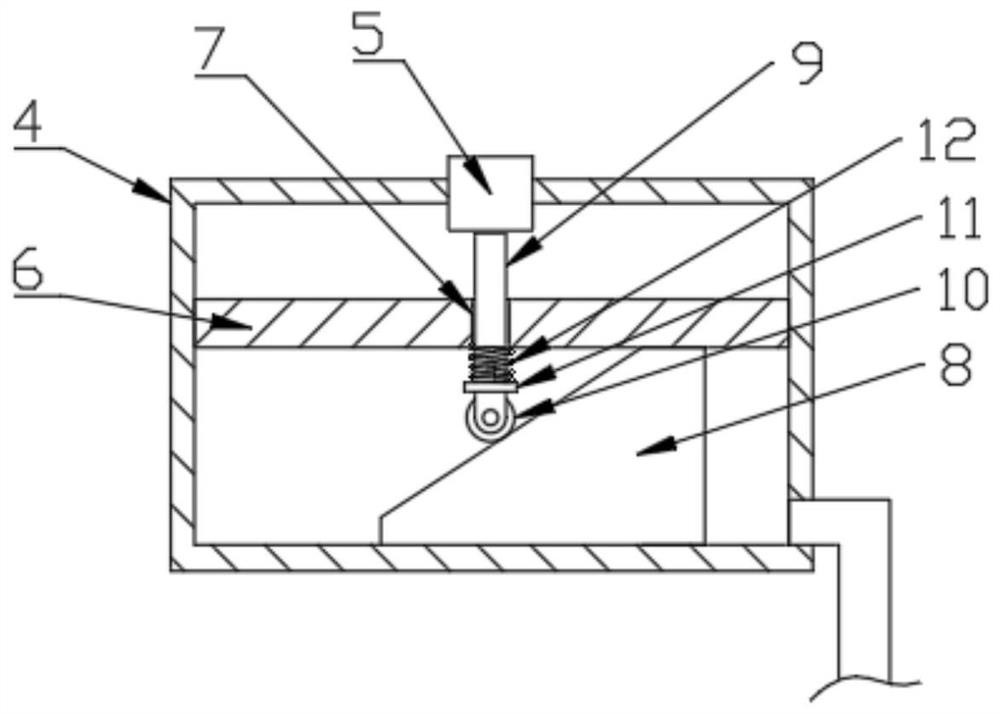

[0031] The housing 4 is provided with a partition 6 arranged horizontally, and the partition 6 is provided with a through hole 7 below the control switch 5, and a slider 8 is provided under the partition 6, and a sliding block 8 is arranged in the through hole 7. There is a lifting rod 9, the bottom of the lifting rod 9 is rotatably connected with a roller 10, and the lifting rod 9 is fixedly provided with a stopper 11 on the rod body above the roller 10, and the lifting rod 9 is positioned between the stopper 11 and the dividing plate 6 The first spring 12 is sheathed on the rod body between them. The slider 8 is sealed and slidably connected between the partition plate 6 and the housing 4, and the top surface of the slider 8 is an inclined plane, and the bottom surface of the roller 10 and the bottom surface of the slider 8 The slopes are in contact, and the inner wal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap