Soil turning device

A body and seat technology, applied in the field of soil pollution remediation, can solve the problems of large piles of soil, the inability of the soil turning device to break up effectively, and insufficient practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

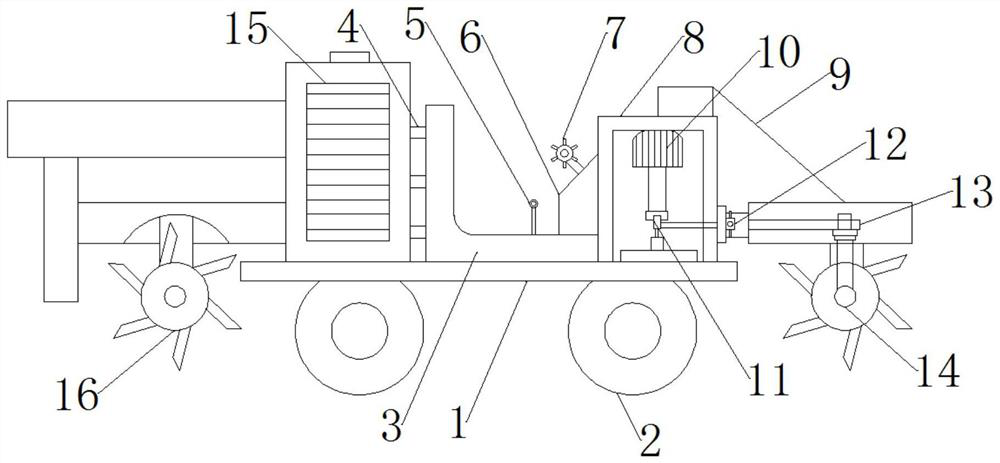

[0022] Example: Figure 1-3 As shown, a turbine device includes a body 1, a wheel 2 and a seat 3, and a wheel 2 is provided at the lower end of the body 1, and the upper end of the body 1 is fixedly connected to the seat 3;

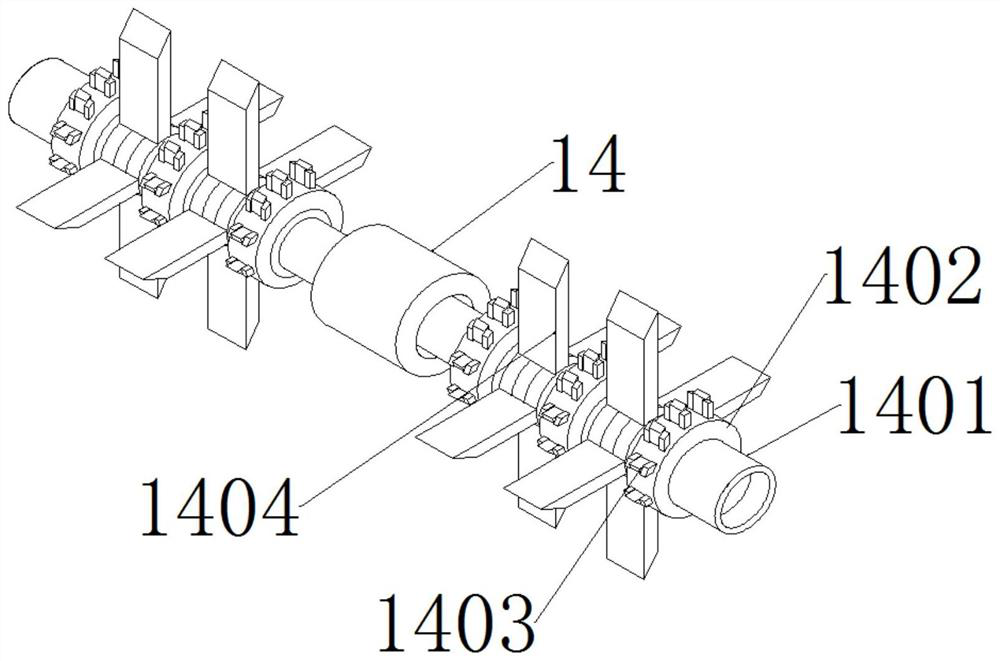

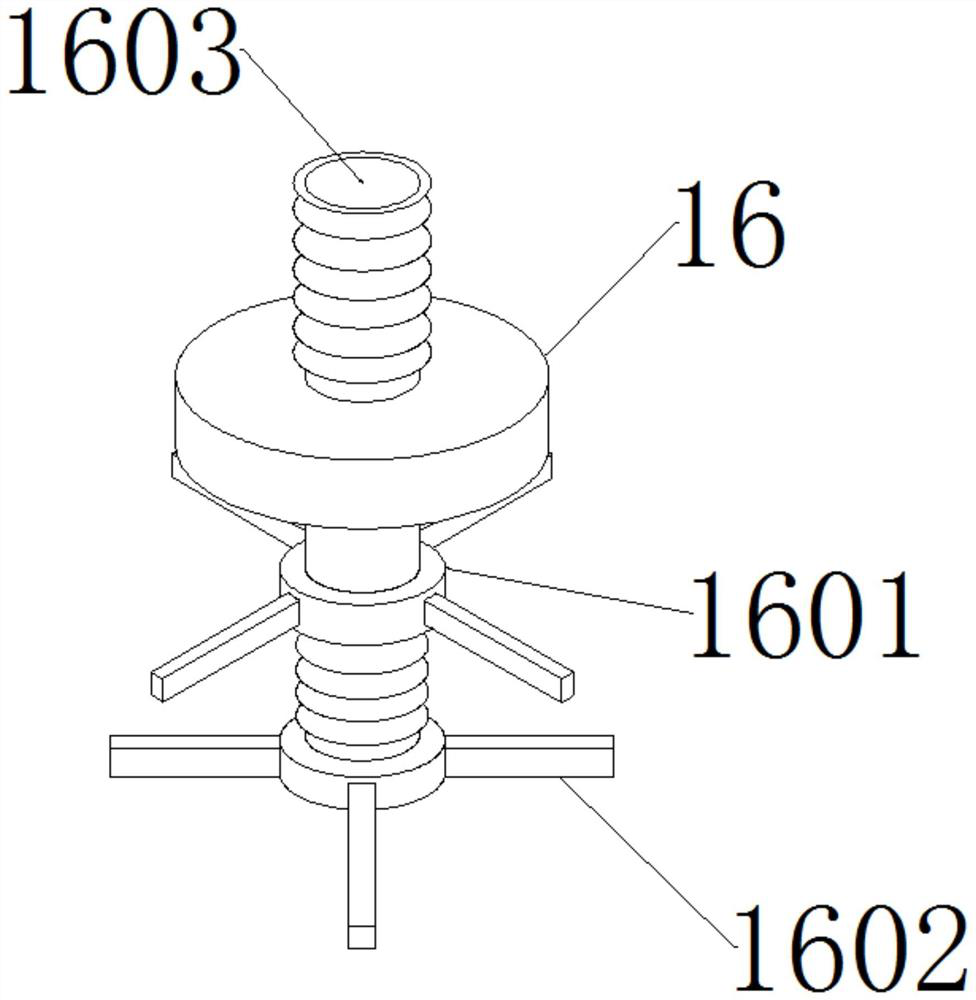

[0023] The rear end of the seat 3 is fixedly connected to the connecting block 4, and the seat 3 is active to be connected to the control rod 5. The front end of the seat 3 is fixedly connected to the European control box 6, and the upper end of the control box 6 is fixedly connected to the steering wheel 7, the control box 6 end The transfer case 8 is fixedly connected, and the front end of the transmission case 8 is fixedly connected to the front baffle 9, and the inner side of the transmission box 8 is fixedly connected to the transmitter 10, the lower end activity of the transmission 10 is connected to the first transmission unit 11, and the first transmission unit 11 is fixed. Connecting an actuator 12, the active device 12 side active is attached to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com