Method for rapidly forming GH4720Li high-temperature alloy forge piece

A technology for superalloys and forgings is applied in the field of rapid prototyping of GH4720Li superalloy forgings, which can solve the problems of long preparation process and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

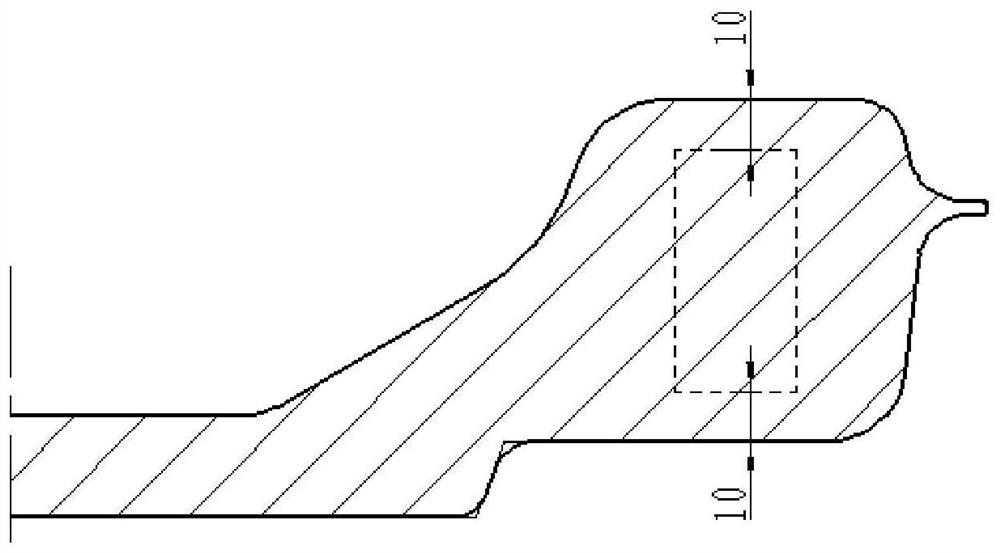

[0065] According to a GH4720LI disc character, select a single-sided 10mm forgings design margin, design simplicity figure 1 Indicated;

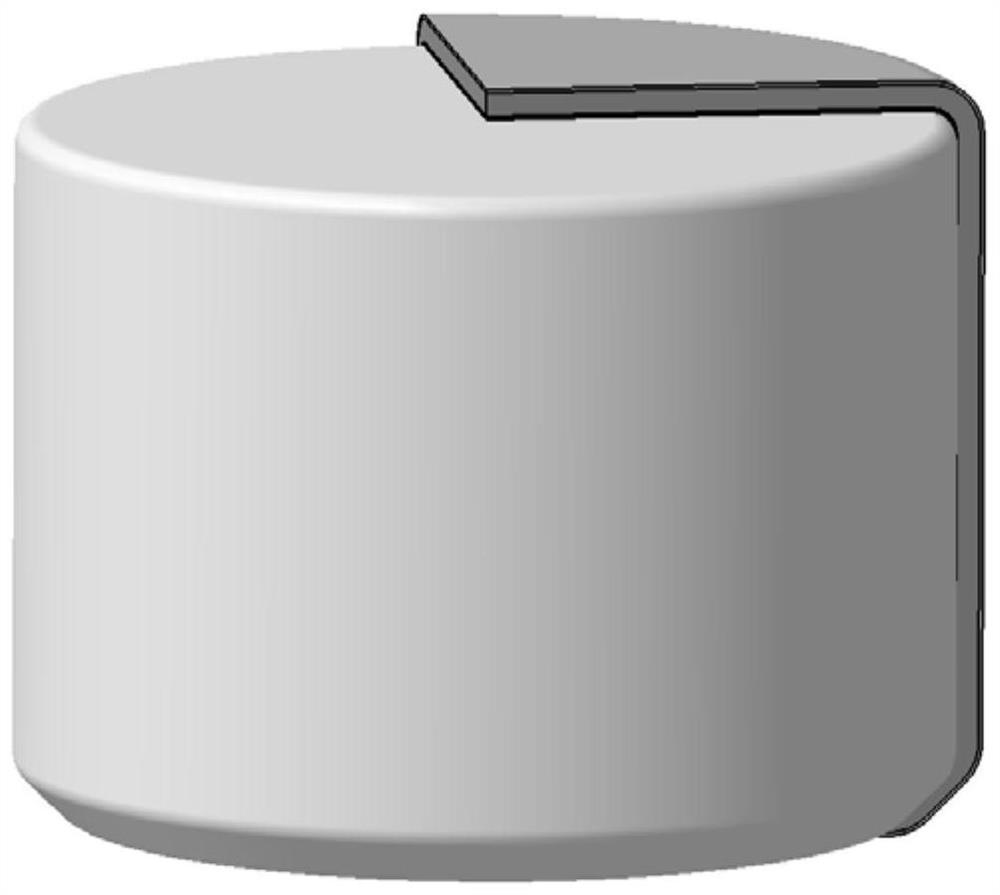

[0066] According to the weight and formation law of GH4720Li disc, the minimum deformation of the bar material in the mold cell during one die forging is selected from 50%, and the amount of the part body deformation is 60% and above. Where the deformation amount is calculated according to the DEFORM software simulated deformation amount x, then according to E x -1 calculates the deformation distribution figure 2 Indicated.

[0067] GH4720LI disc stick material uses composite package, such as image 3 , Figure 4 As shown, first, the base is wrapped in a normal temperature state, and the fiber cloth of 0.2 mm thick graphite is applied, and the thickness of the thickness of 0.3 mm, and then wraps a thickness of 5 mm, a thickness of 5 mm, and then wrapped in the outer surface of the fiber. Cotton, and finally in the outer surface with a 0.8 mm thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com