Drilling device for mechanical intelligent manufacturing

A drilling device and mechanical intelligence technology, applied in positioning devices, manufacturing tools, boring/drilling, etc., can solve the problems of simultaneous processing of multiple holes, high labor intensity, cumbersome operation, etc., and achieve compact structure, The effect of low labor intensity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

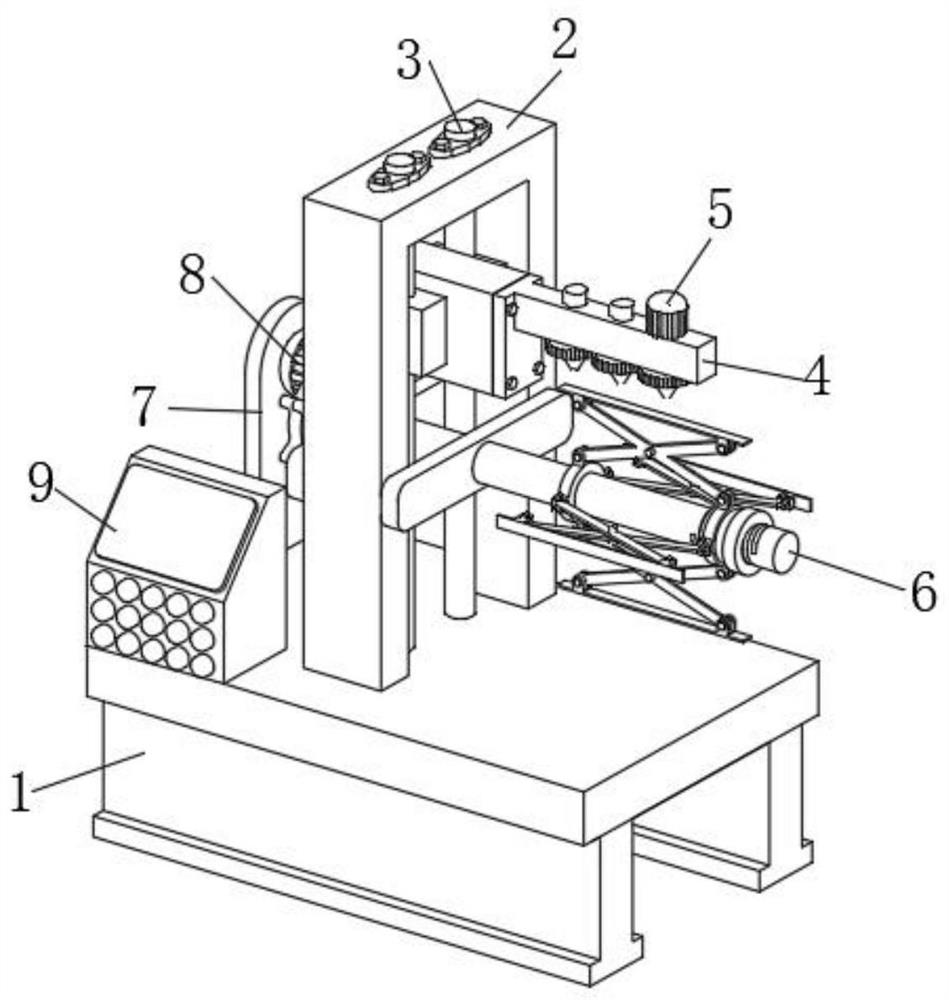

[0033] A drilling device for mechanical intelligent manufacturing, such as Figure 1-2 As shown, including the console 1, the middle part of the upper end of the console 1 is fixedly equipped with a fixed frame 2, the fixed frame 2 is a U-shaped structure, and a fixed rod 3 is interspersed and connected to the left and right sides of the upper end of the fixed frame 2, and two The lower end of the fixed rod 3 is fixedly installed with the upper end of the console 1, and a lifting mechanism 4 is jointly slidably connected between the two fixed rods 3, and a drilling mechanism 5 is interspersed in the front part of the upper end of the lifting mechanism 4, and the drilling mechanism 5 is movably connected with the lifting mechanism 4 through bearings, and a turning mechanism 6 is interspersed in the middle part of the front end of the fixed frame 2, and is located below the lifting mechanism 4. A driving mechanism 8 is fixedly installed in the front end of the front end, and the...

Embodiment 2

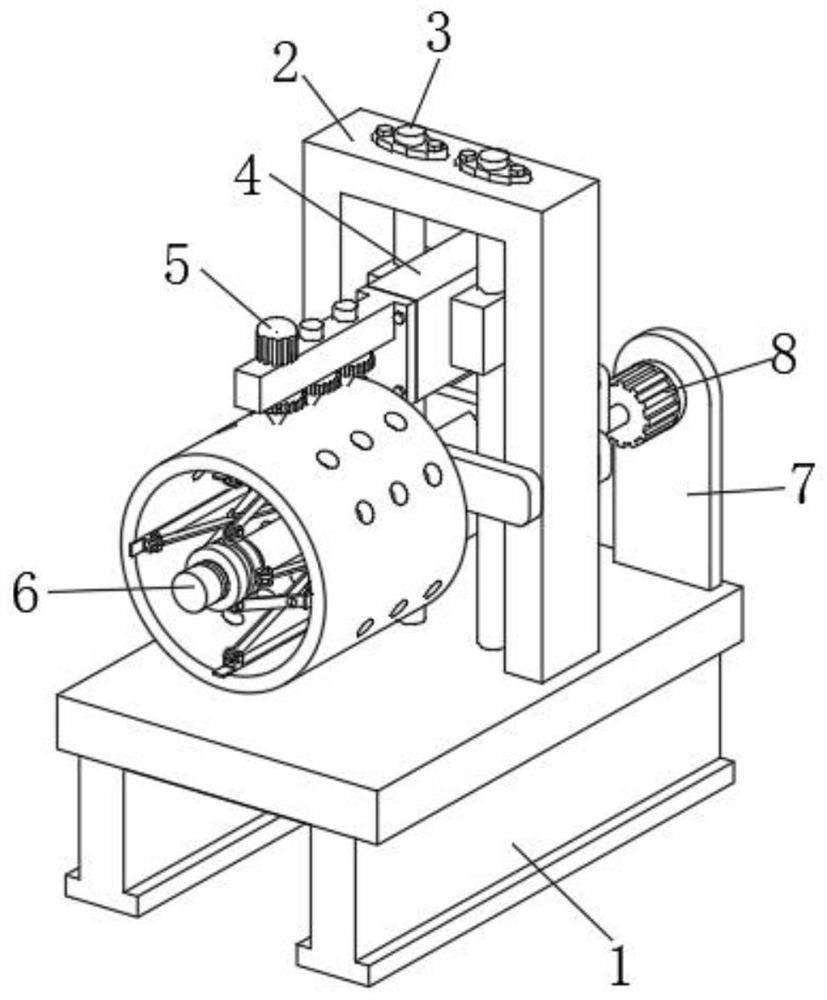

[0036] On the basis of Example 1, as Figure 3-4 As shown, a drilling device for mechanical intelligent manufacturing includes a console 1, a fixed frame 2 is fixedly installed in the middle of the upper end of the console 1, the fixed frame 2 is a U-shaped structure, and the left and right sides of the upper end of the fixed frame 2 are interspersed A fixed rod 3 is connected, and the lower ends of the two fixed rods 3 are fixedly installed with the upper end of the console 1, and a lifting mechanism 4 is jointly slidably connected between the two fixed rods 3, and the front part of the upper end of the lifting mechanism 4 is connected with a A drilling mechanism 5, and the drilling mechanism 5 is movably connected with the lifting mechanism 4 through bearings, a turning mechanism 6 is interspersed in the middle part of the front end of the fixed frame 2, and is located below the lifting mechanism 4, and the upper end of the console 1 is fixed at the rear A fixed plate 7 is i...

Embodiment 3

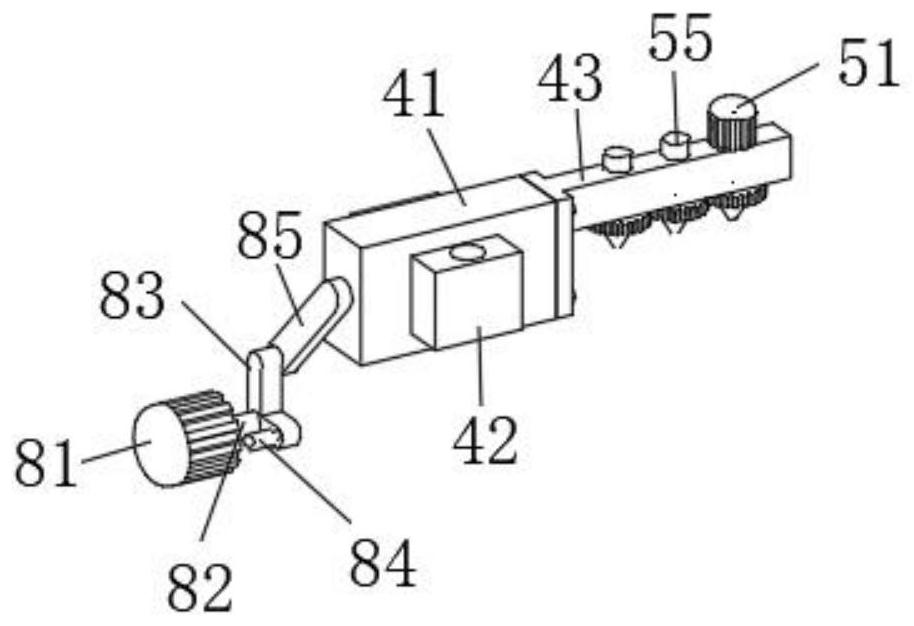

[0039] On the basis of Example 1, as Figure 5-8 As shown, a drilling device for mechanical intelligent manufacturing includes a console 1, a fixed frame 2 is fixedly installed in the middle of the upper end of the console 1, the fixed frame 2 is a U-shaped structure, and the left and right sides of the upper end of the fixed frame 2 are interspersed A fixed rod 3 is connected, and the lower ends of the two fixed rods 3 are fixedly installed with the upper end of the console 1, and a lifting mechanism 4 is jointly slidably connected between the two fixed rods 3, and the front part of the upper end of the lifting mechanism 4 is connected with a A drilling mechanism 5, and the drilling mechanism 5 is movably connected with the lifting mechanism 4 through bearings, a turning mechanism 6 is interspersed in the middle part of the front end of the fixed frame 2, and is located below the lifting mechanism 4, and the upper end of the console 1 is fixed at the rear A fixed plate 7 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com