Aluminum pipe cutting machine

A technology for cutting machines and aluminum tubes, applied in the direction of pipe shearing devices, shearing devices, and accessories of shearing machines, etc., can solve the problem of large tape consumption, achieve the effect of saving tapes and increasing work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

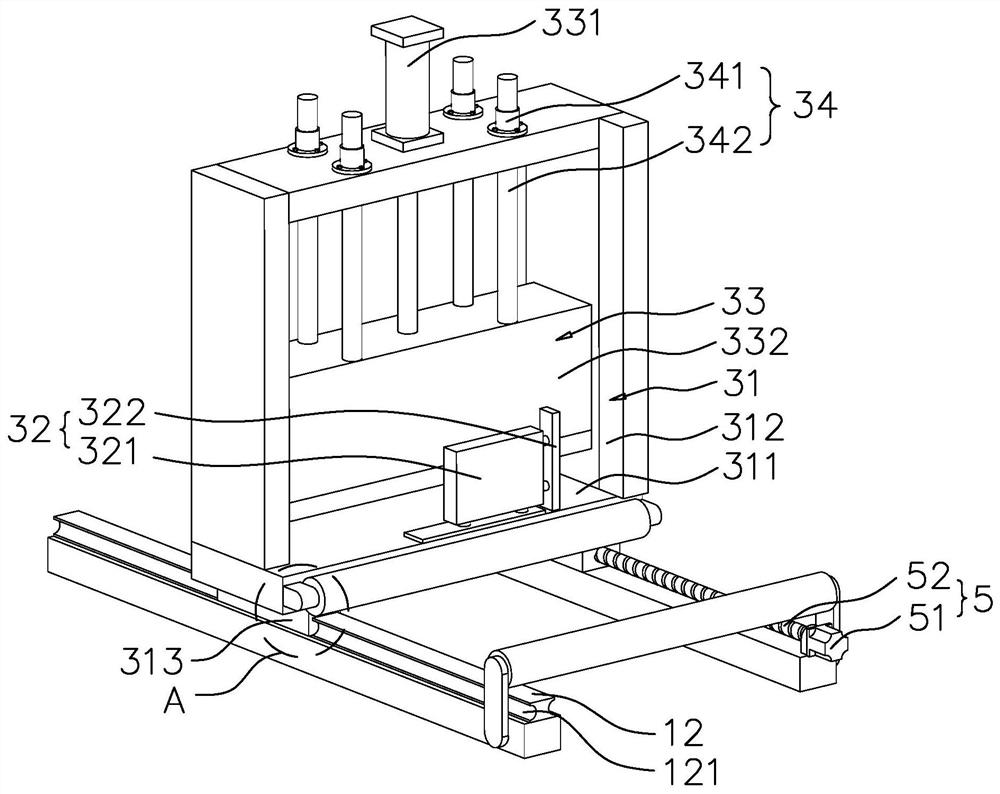

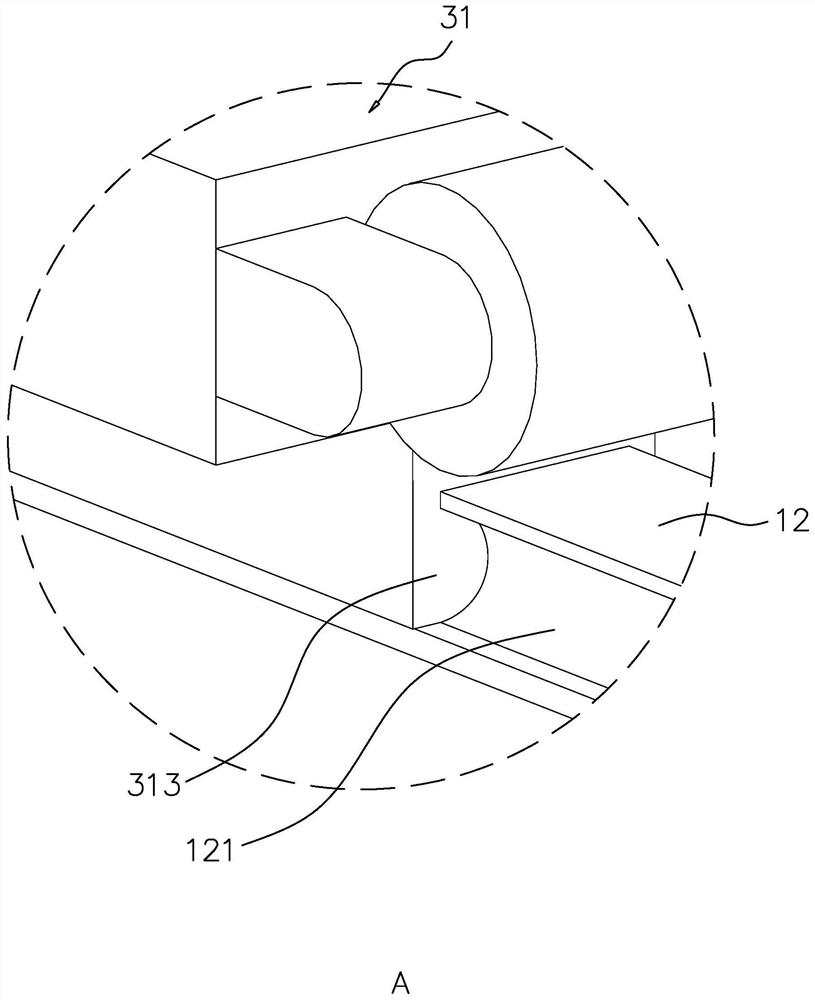

[0037] The following is attached Figure 1-6 The application is described in further detail.

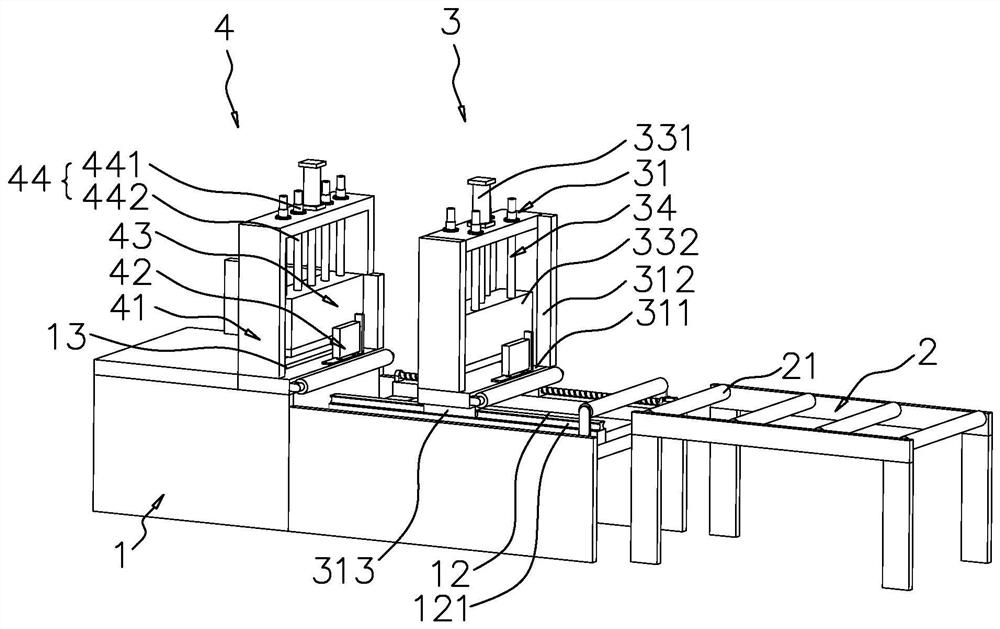

[0038] The embodiment of the present application discloses an aluminum pipe cutting machine. refer to figure 1 , the aluminum pipe cutting machine includes a support frame 1, a conveying assembly 2 and a cutting knife (not shown in the figure), the conveying assembly 2 is located on one side in the length direction of the support frame 1, and the conveying assembly 2 includes a frame body and several conveying rollers 21 , several conveying rollers 21 are installed on the frame body, the conveying rollers 21 are cylindrical, several conveying rollers 21 are arranged along the length direction of the support frame 1, and the conveying rollers 21 are rotatably connected with the frame body. In this embodiment, the conveying There are four rollers 21 . Therefore, placing the aluminum tube on the conveying roller 21 enables the aluminum pipe to be transported through the conveying rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com