Brazing connection method for aluminum alloy and magnesium alloy

A connection method and technology of aluminum alloys, applied in welding medium, welding equipment, welding/welding/cutting items, etc., can solve the problems of ineffectiveness, cracks and pores, poor weldability of fusion welding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

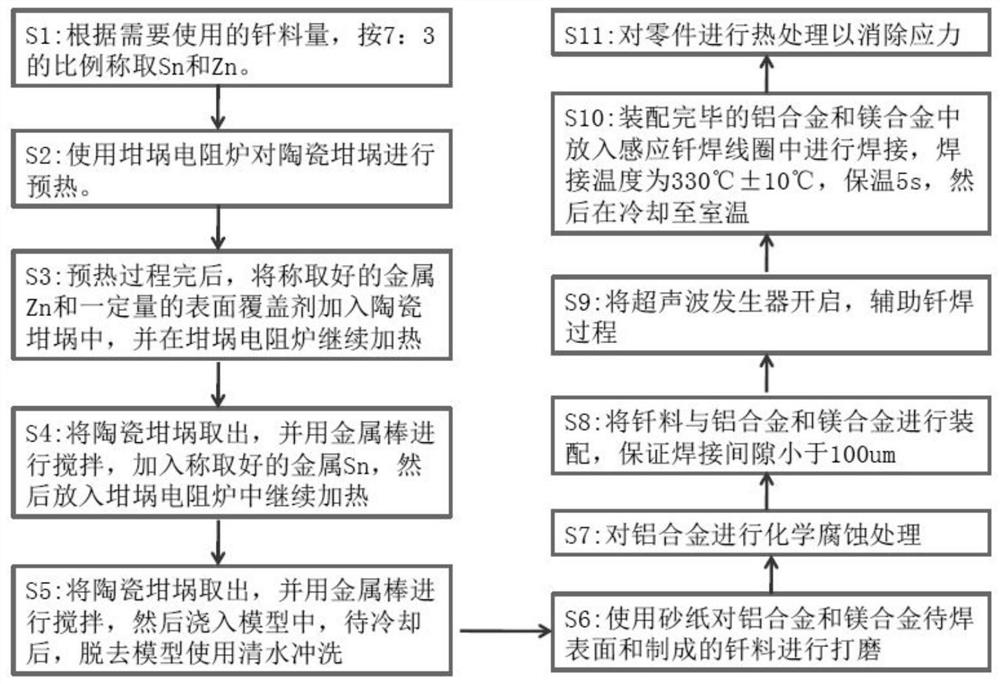

[0029] combine figure 1 , a brazing connection method of an aluminum alloy and a magnesium alloy of the present invention, comprising the following steps:

[0030] S1: Accurately weigh the metal Sn and metal Zn according to the ratio of 7:3 according to the amount of brazing material to be used, and the weighing is accurate to 0.01g;

[0031] S2: Preheat the ceramic crucible with a crucible resistance furnace, and the preheating temperature of the crucible resistance furnace is 300°C±10°C;

[0032] S3: After the preheating process, add the eutectic mixture of metal Zn and a certain amount of surface covering agent KCl / LiCl weighed in step S1 into the ceramic crucible. The amount of surface covering agent used depends on whether Zn is completely covered. without exposure to air. And continue heating in the crucible resistance furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap