Rapid aluminum-titanium alloy polishing equipment for high-end manufacturing

An aluminum-titanium alloy, fast technology, applied in the direction of grinding/polishing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient operation, high radiation intensity, weak radiation intensity, etc., and achieve the effect of scraping dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A high-end manufacturing aluminum-titanium alloy rapid polishing equipment, such as figure 1 As shown, it includes base plate 1, workbench 2, primary material guide mechanism 3 and primary polishing mechanism 4, base plate 1 is provided with workbench 2, workbench 2 is provided with primary material guide mechanism 3, and the top of workbench 2 Primary polishing mechanism4.

[0071] When people want to polish aluminum-titanium alloys, they can use this high-end aluminum-titanium alloy rapid polishing equipment for manufacturing. First, the user starts the primary material guide mechanism 3 to feed the aluminum-titanium alloy from the inlet of the primary material guide mechanism 3. Putting in, the aluminum-titanium alloy enters the primary polishing mechanism 4 through the primary material guide mechanism 3, and the primary polishing mechanism 4 polishes the aluminum-titanium alloy. After the aluminum-titanium alloy is polished, the primary material guide mechanism 3 is...

Embodiment 2

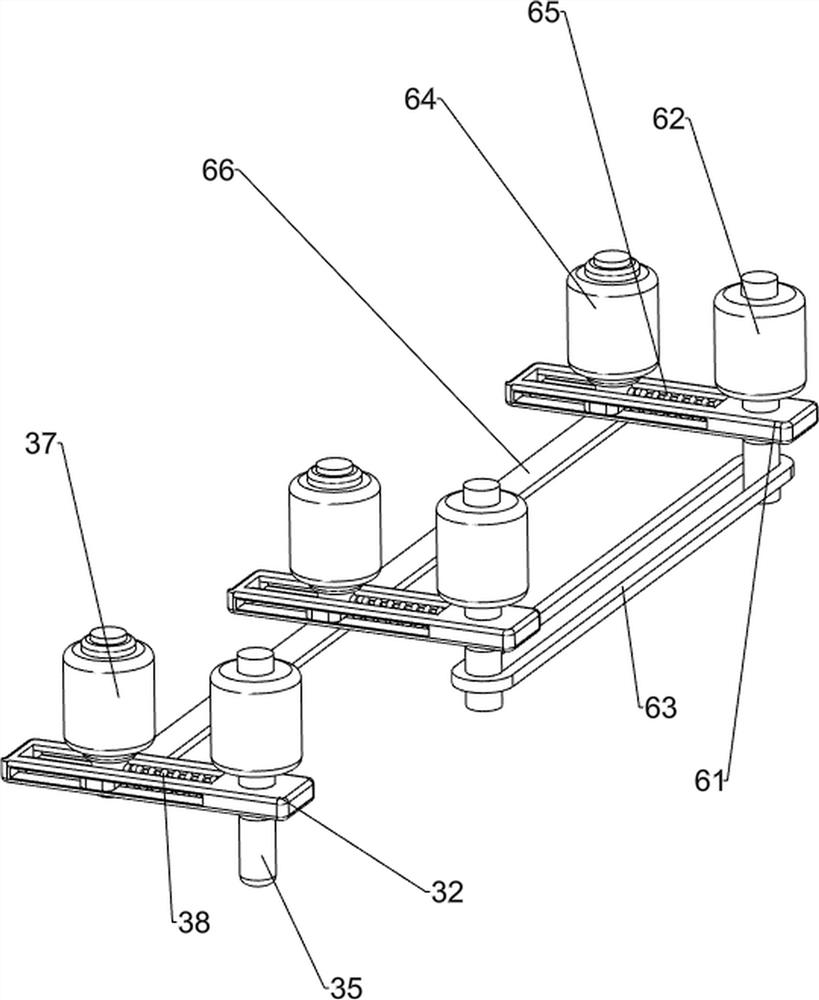

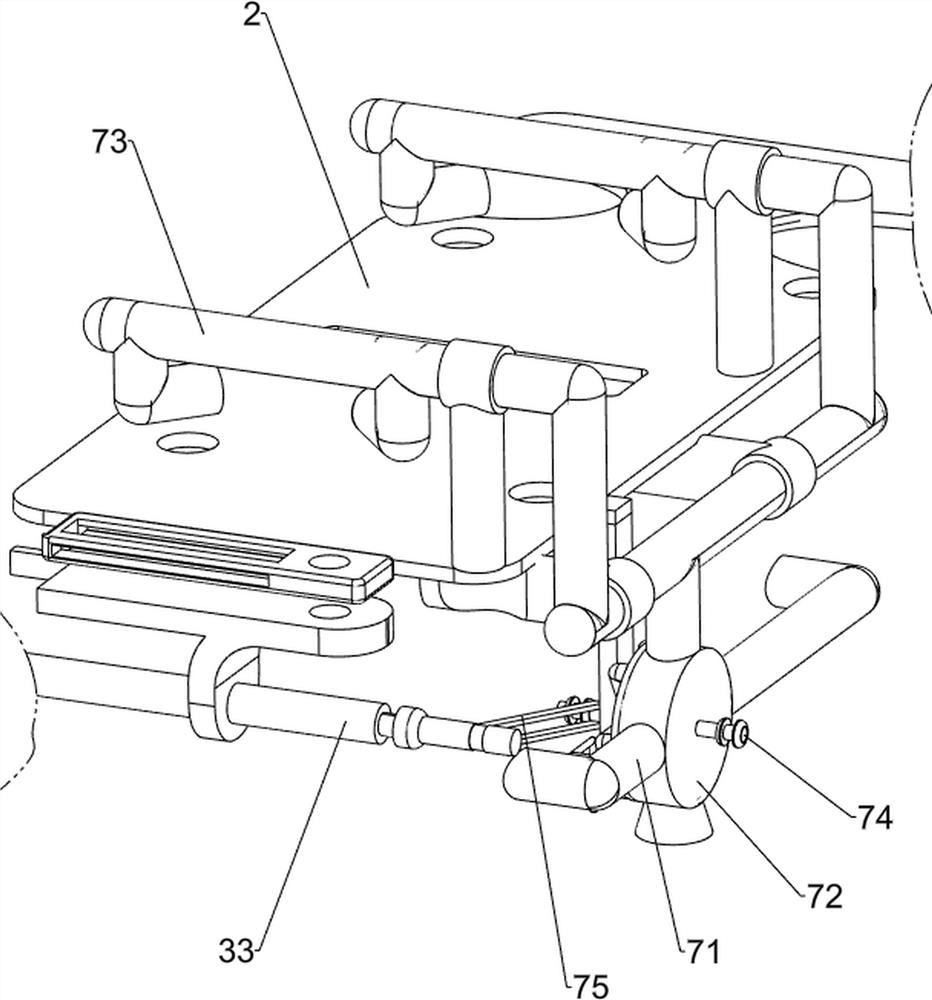

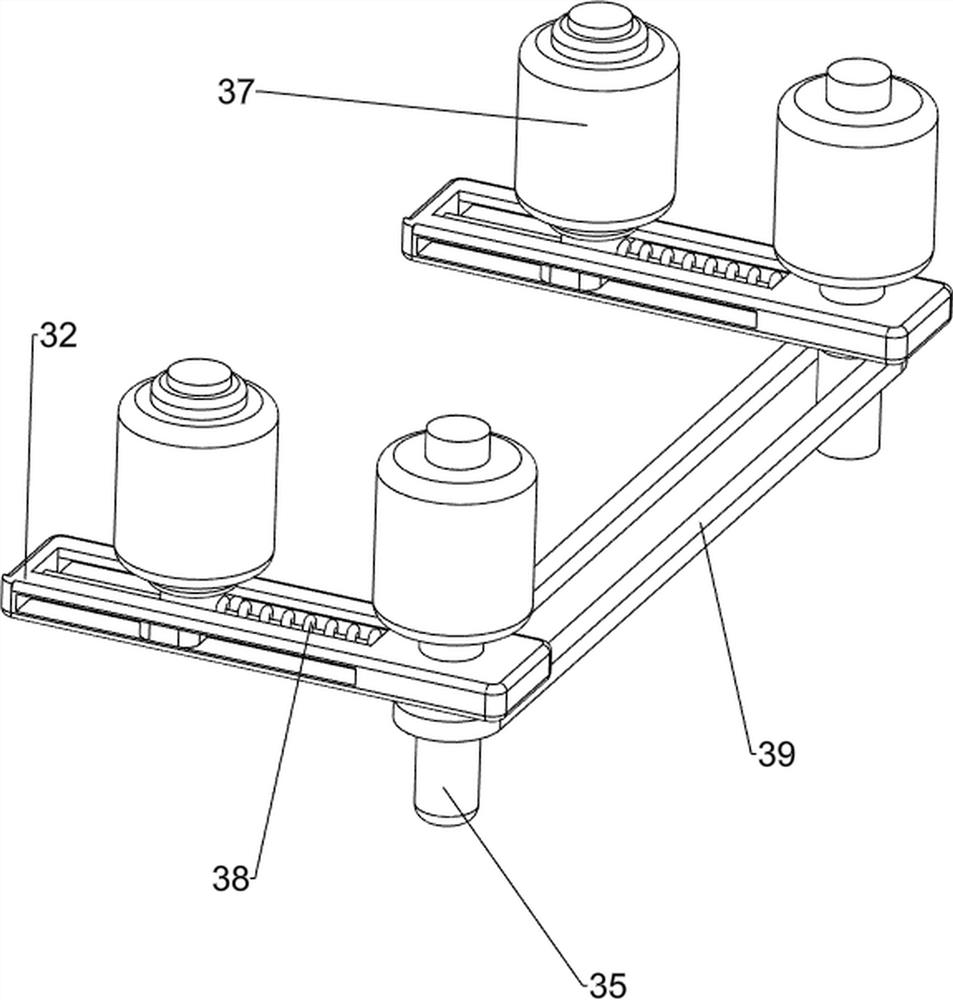

[0073] On the basis of Example 1, such as Figure 2-Figure 4 As shown, the primary material guide mechanism 3 includes a motor 31, a first fixed frame 32, a first transmission shaft 33, a first pulley assembly 34, a main material pulley 35, a first reversing gear set 36, a secondary material guide wheel 37, The first spring 38 and the second pulley assembly 39, the left part of the front side of the workbench 2 is equipped with a motor 31, the front side and the middle part of the workbench 2 are provided with the first fixed frame 32, and the front side of the workbench 2 is rotatably provided with the first fixed frame 32. A transmission shaft 33, a first pulley assembly 34 is connected between the output shaft of the motor 31 and the first transmission shaft 33, the right sides of the two first fixed frames 32 are provided with a leading material wheel 35, and the leading material wheel 35 on the front side drives The first reversing gear set 36 is connected between the sha...

Embodiment 3

[0078] On the basis of Example 2, such as Figure 5-Figure 9 As shown, an auxiliary polishing mechanism 5 is also included, and the rear side of the workbench 2 is provided with an auxiliary polishing mechanism 5. The auxiliary polishing mechanism 5 includes a main fine polishing wheel 51, an auxiliary fine polishing wheel 52, a fourth pulley assembly 53 and a fifth pulley Component 54, the top rear left part of the workbench is provided with a main fine polishing wheel 51, the top rear right part of the workbench 2 is rotatably provided with an auxiliary fine polishing wheel 52, the main polishing wheel 41 and the main fine polishing wheel 51 A fourth pulley assembly 53 is connected between them, and a fifth pulley assembly 54 is connected between the main fine polishing wheel 51 and the auxiliary fine polishing wheel 52 .

[0079] When the main polishing wheel 41 rotates, the main polishing wheel 41 drives the fourth pulley assembly 53 to rotate, thereby driving the main fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com