Adjustable die for processing silicone bracelet and use method of adjustable die

An adjustable and silicone technology, which is applied in the field of adjustable molds for the processing of silicone bracelets, can solve the problems of reduced processing efficiency and achieve the effect of improving efficiency and preventing overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

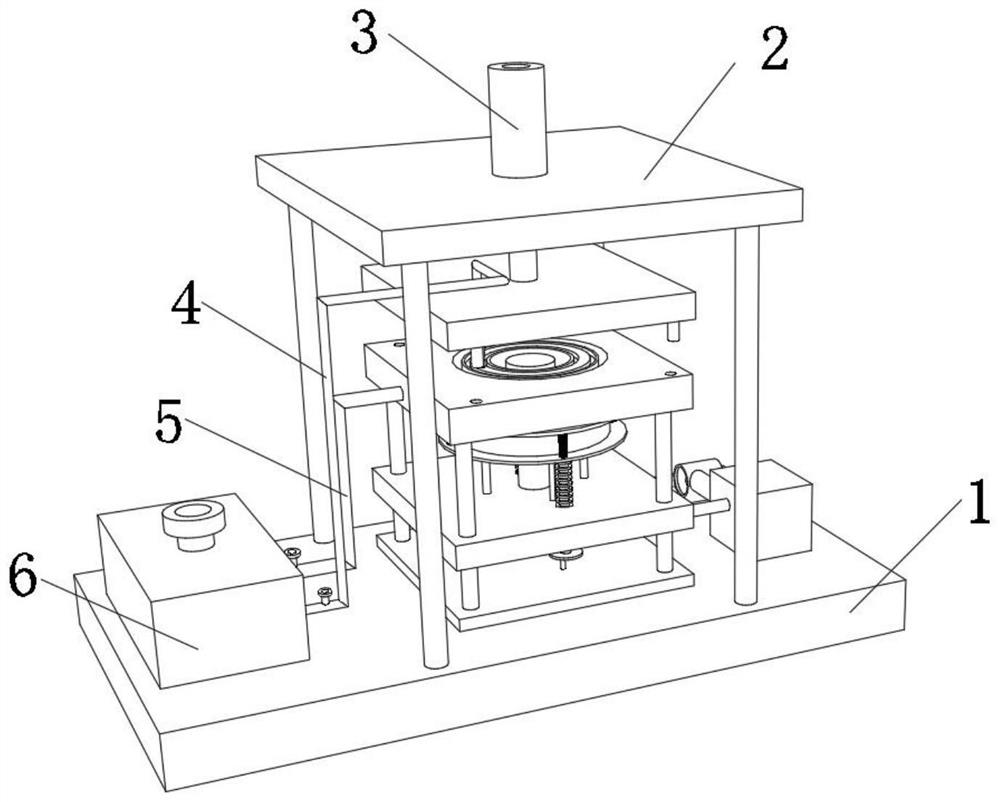

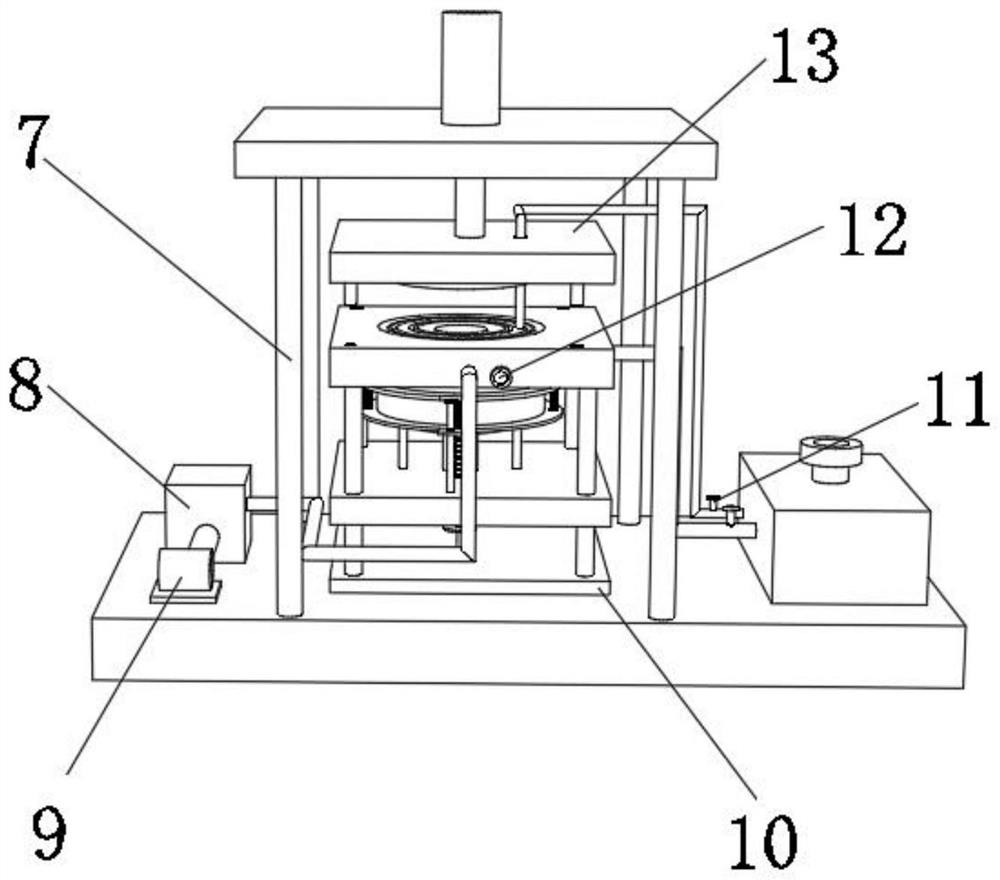

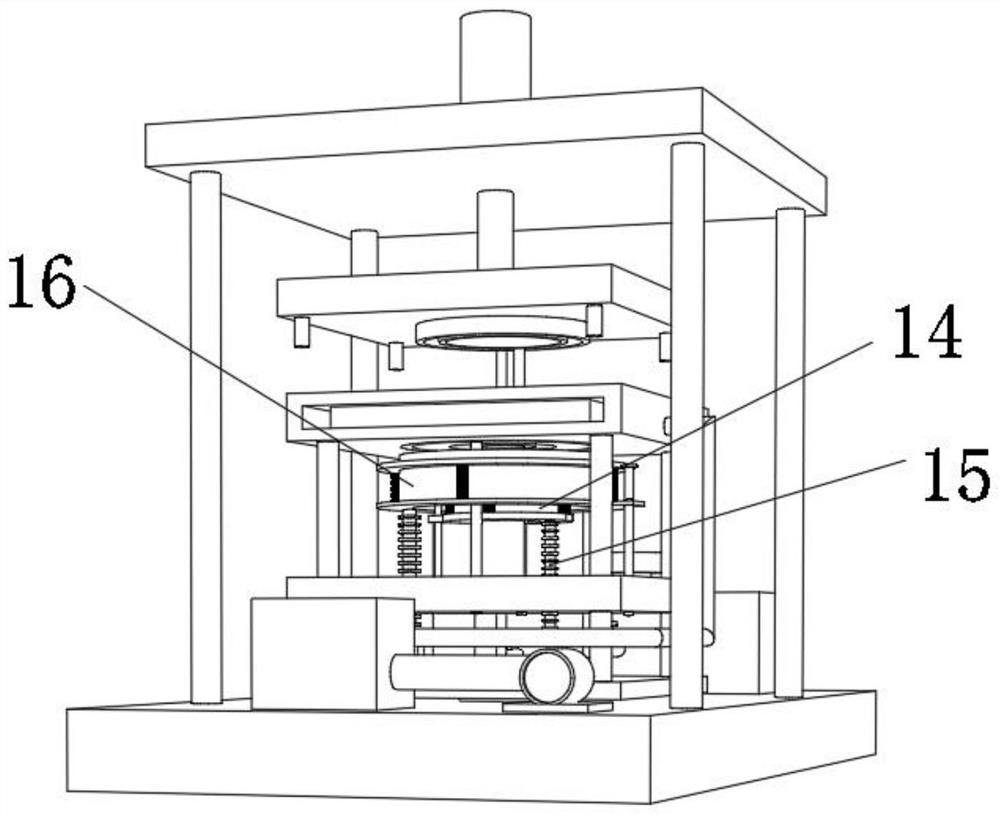

[0047] An adjustable mold for silicone bracelet processing, such as Figure 1-8 As shown, it includes a support base 1 and a lower mold base 22. The outer wall of the bottom of the lower mold base 22 is fixed with four guide posts 21 by bolts, and the outer walls of the four guide posts 21 are fixed with a base 20 by screws. The outer wall of the top of the mold base 22 is provided with an accommodating cavity 26, and the outer wall of the top of the base 20 is fixed with a first limiting column 18 and a second limiting column 25 by screws, and the outer wall of the top of the base 20 is rotatably connected with two screw rods 15. The top outer walls of the two screw rods 15 are respectively connected with a first adjusting column 14 and a second adjusting column 16 through bearings, and both the first adjusting column 14 and the second adjusting column 16 are hollow structures, and the first adjusting column 14 The circumferential inner wall is slidably connected to the circu...

Embodiment 2

[0056] A kind of using method of the adjustable mold that is used for the processing of silicone bracelet described in embodiment 1, comprises the following steps:

[0057] S1: Connect the card block 19 to the inner wall of the card slot 35;

[0058] S2: Select the mold cavity according to the diameter of the silicone bracelet;

[0059] S3: Turn the screw 15 to make the first adjusting column 14 or the second adjusting column 16 close the selected mold cavity;

[0060] S4: Using the cylinder 3 to drive the upper mold base 13 to clamp the lower mold base 22;

[0061]S5: injecting silica gel into the first leakage hole 23 or the second leakage hole 24 by using the first rubber injection pipe 4 or the second rubber injection pipe 5, and injecting glue into the selected mold cavity;

[0062] S6: Use the cooling assembly 8 and the blower 9 to deliver cold air inside the cross-shaped air duct 17 to cool the silica gel;

[0063] S7: Turn the screw rod 15 to drive the first adjusti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap