3D printing model intelligent preprocessing method and device based on design component information

A technology of 3D printing and component information, applied in manufacturing auxiliary devices, design optimization/simulation, computer-aided design, etc., can solve problems such as difficult for beginners to get started quickly, low efficiency, inability to integrate and optimize dimensional accuracy in depth, and achieve convenient preprocessing quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

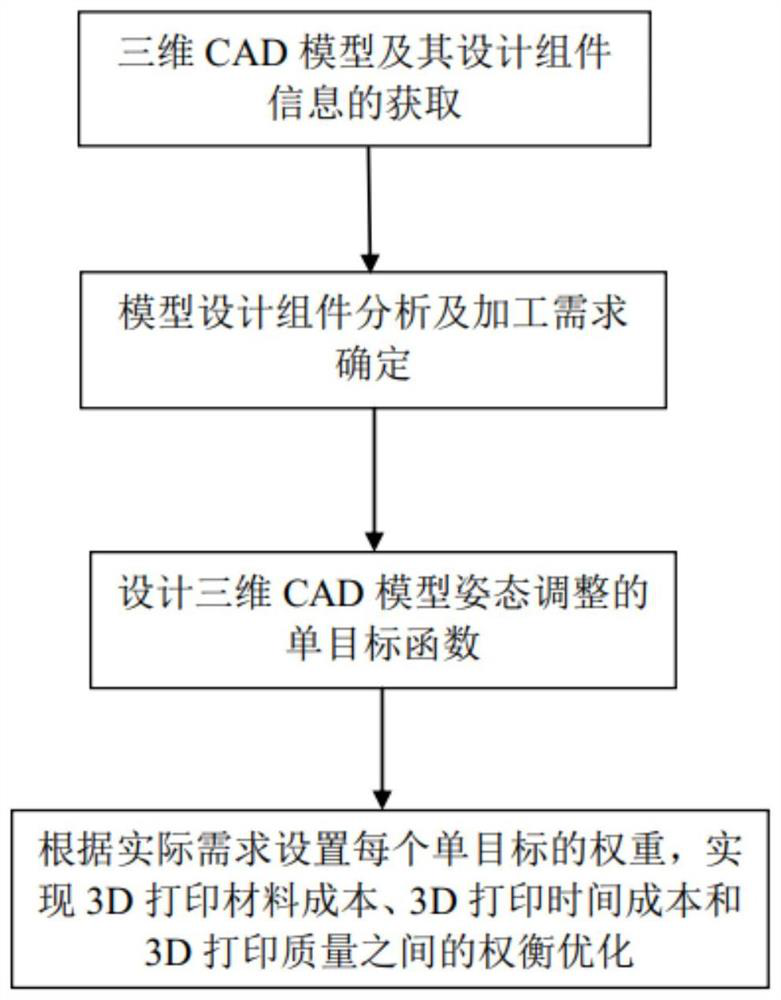

[0060] Such as figure 1 As shown, a 3D printing model intelligent preprocessing method based on design component information, specifically includes the following steps:

[0061] Step (1), obtain the three-dimensional CAD model of the removable partial denture and its design component information, the above-mentioned design component information can be obtained directly through the design stage of the 3D printing model, or it can be the three-dimensional information semantic analysis module obtained through machine learning training in advance ( For prior art) analysis 3D printing model obtains.

[0062] In the 3D printing model design stage, through the development of component information recording tools, while outputting the 3D CAD model, the information of each design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com