Anti-counterfeiting material and manufacturing method

A manufacturing method and a technology of luminescent materials, which are applied to printing and information-carrying cards, etc., can solve the problems of poor anti-counterfeiting effect of anti-counterfeiting materials, and achieve good anti-counterfeiting effects, reliable quality, and simple and quick manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

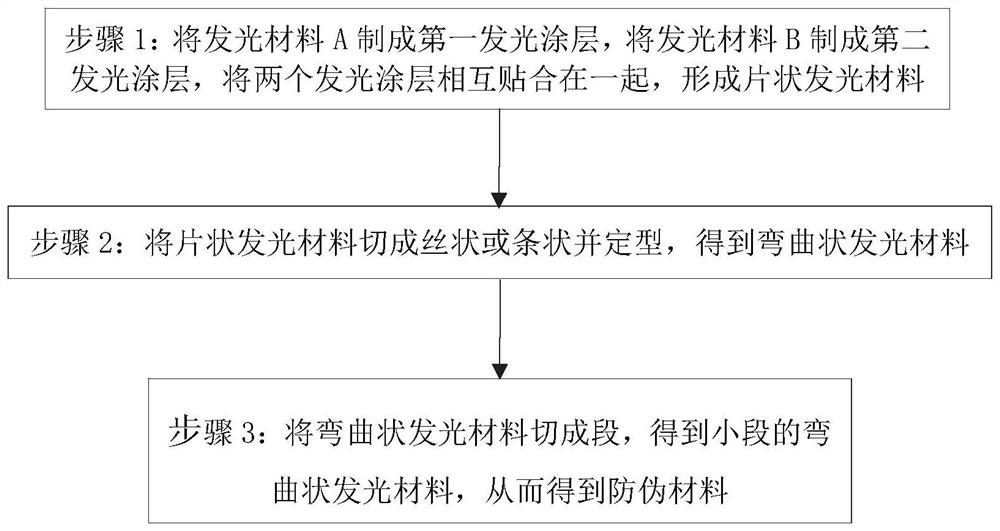

[0032] like figure 1 , Figure 4-Figure 6 Shown, a kind of anti-counterfeiting material manufacturing method comprises the steps:

[0033] Step 1: Make the luminescent material A into the first luminescent coating, and make the luminescent material B into the second luminescent coating, and the first luminescent coating is directly attached to the second luminescent coating, so that the two luminescent coatings are back to back Fitted together to form an overall coating of luminous material. That is, one surface of the first luminescent coating and one surface of the second luminescent coating are bonded together to form a sheet-shaped luminescent material, and the first luminescent coating and the second luminescent coating are aligned along the axis of the sheet. The directions (ie, lengthwise) extend in parallel. Luminescent material A and luminescent material B are two kinds of materials with different photoluminescent properties. For example, luminescent material A is ...

Embodiment 2

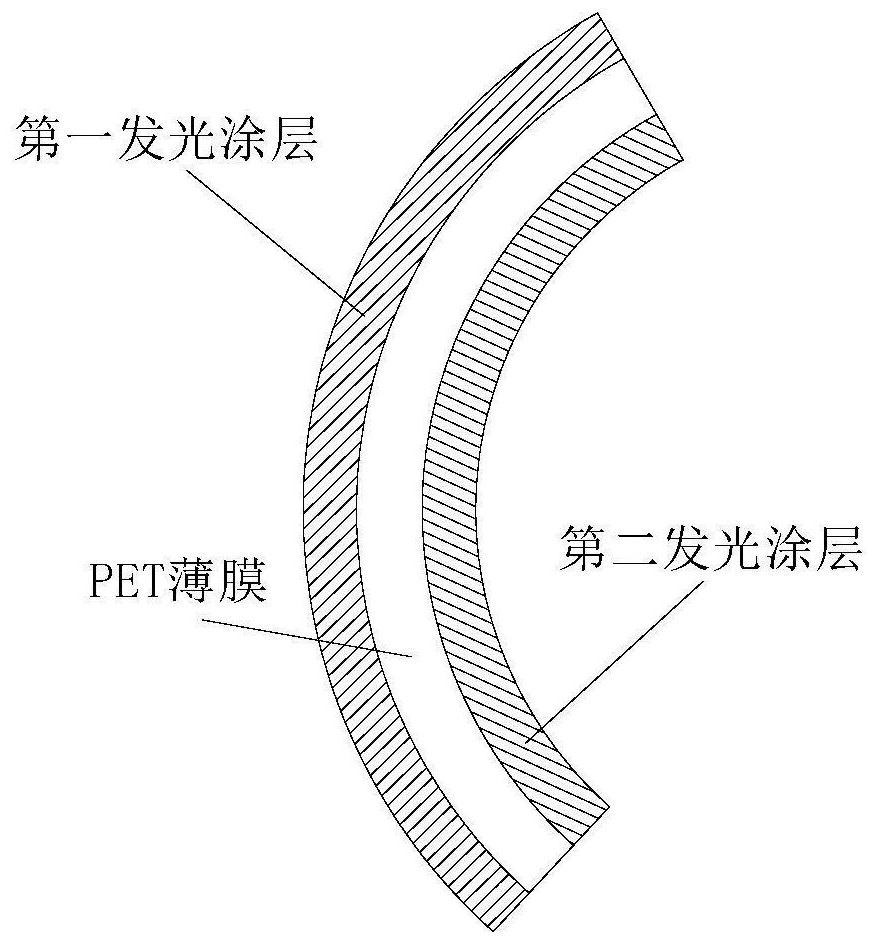

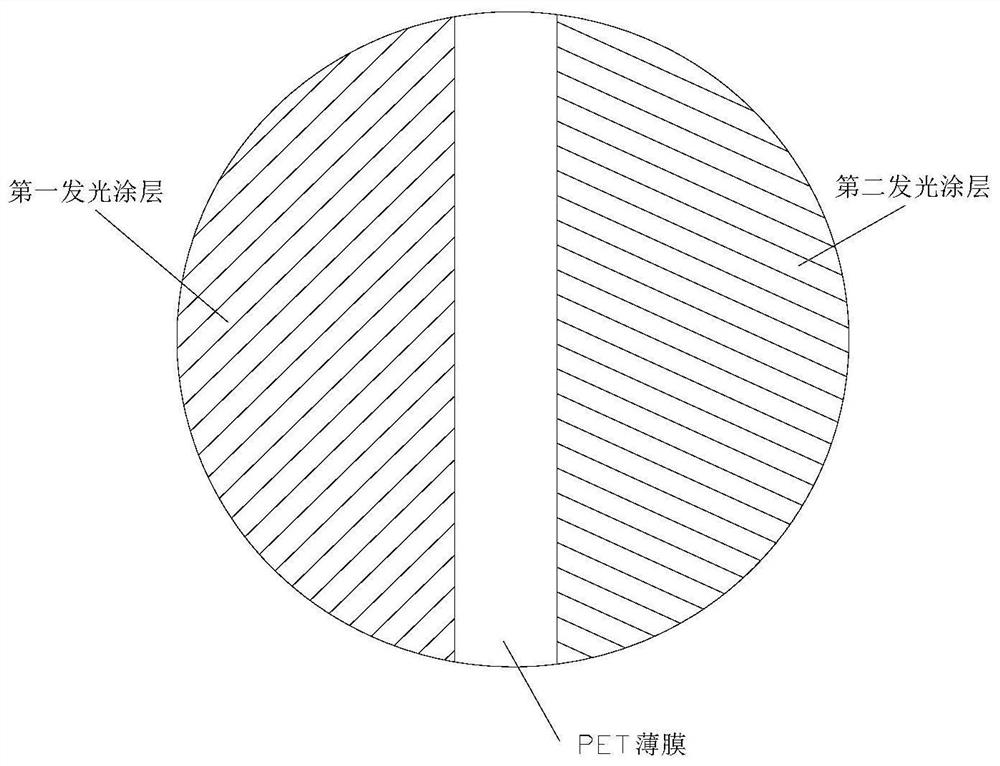

[0041] refer to Figure 1-Figure 3 , Image 6 As shown, the first embodiment is to bond the luminescent material A and the luminescent material B together. The difference from the first embodiment is that in this embodiment, in step 1, the luminescent material A and the luminescent material B are respectively painted on a transparent surface. On the two opposite surfaces of the light-transmitting sheet, a first luminescent coating and a second luminescent coating are respectively formed on the two surfaces of the light-transmitting sheet. The light-transmitting sheet is preferably a transparent PET film. The PET film has good temperature resistance, high mechanical strength, is convenient for processing and setting, and is not suitable for heat deformation after setting.

[0042] When the light-transmitting sheet is a PET film, paint the luminescent material A on one surface of the PET film to form a first luminescent coating, and paint the luminescent material B on the other...

Embodiment 3

[0049] In Embodiment 1 and Embodiment 2, both luminescent material A and luminescent material B can transmit visible light. In this embodiment, at least one of the luminescent materials in luminescent material A and luminescent material B is opaque to visible light, including luminescent material A as Transmitting visible light, luminescent material B is opaque to visible light, luminescent material A is opaque to visible light, luminescent material B is transparent to visible light, both luminescent material A and luminescent material B are opaque to visible light. At this time, the first luminescent coating and the second luminescent coating composed of luminescent material A and B can only see the luminous color when the human eye is on the same side as the excitation light, that is, the human eye can see the luminescent color at a specific position. Glowing color.

[0050] Taking the luminescent material A as transparent to visible light and the luminescent material B as o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com