Method for stacking inner cores convenient to take for battery production line

A technology in the production line and battery, applied in the field of inner core stacking, can solve the problems of delaying the work of the production line, difficulty in looking back or recounting, large amount of battery inner cores, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

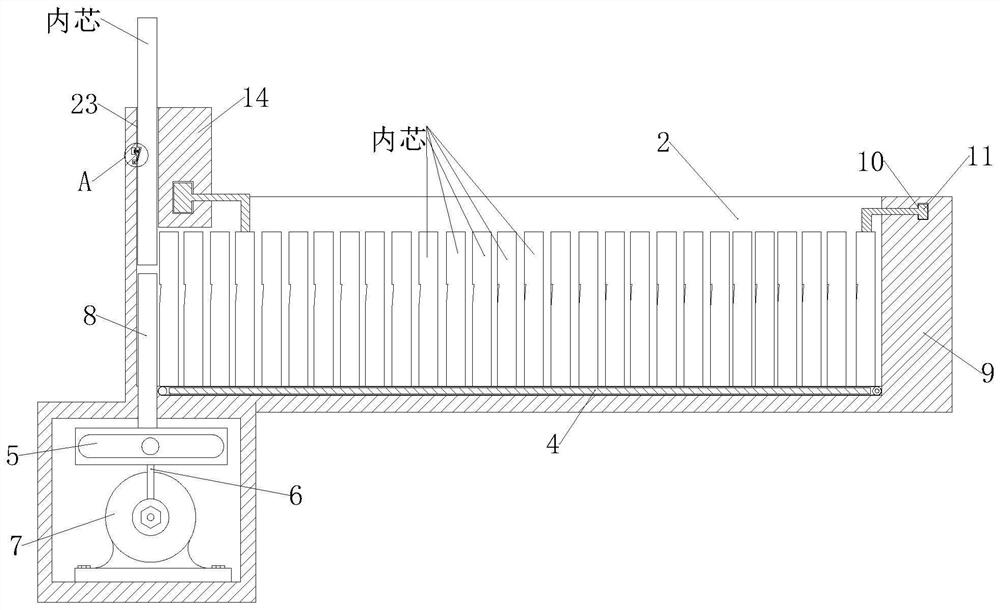

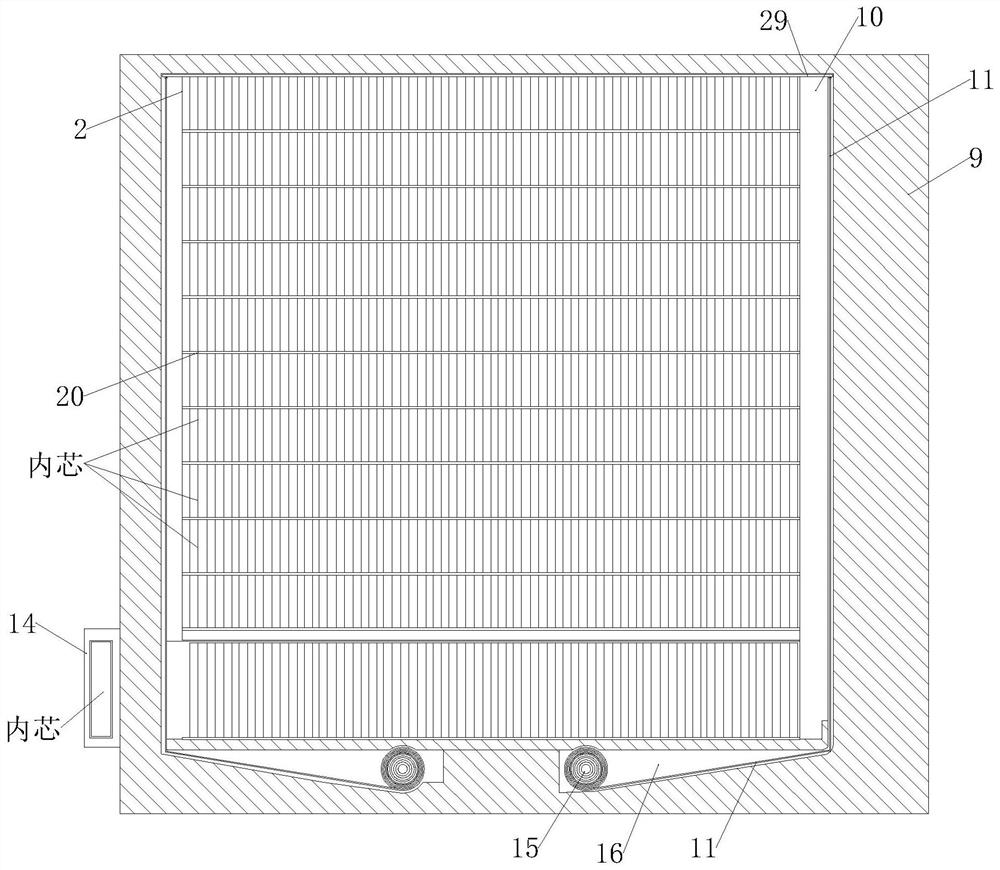

[0036] In order to make the technique of the present invention, the creation characteristics, the achievement and the efficiency are readily understood, and the present invention is further illustrated in connection with the present invention, and it is to be explained, and the embodiments in the present application are described below. The features in the examples can be combined with each other.

[0037] See Figure 1-7 For a battery production line for easy-to-take the end stack,

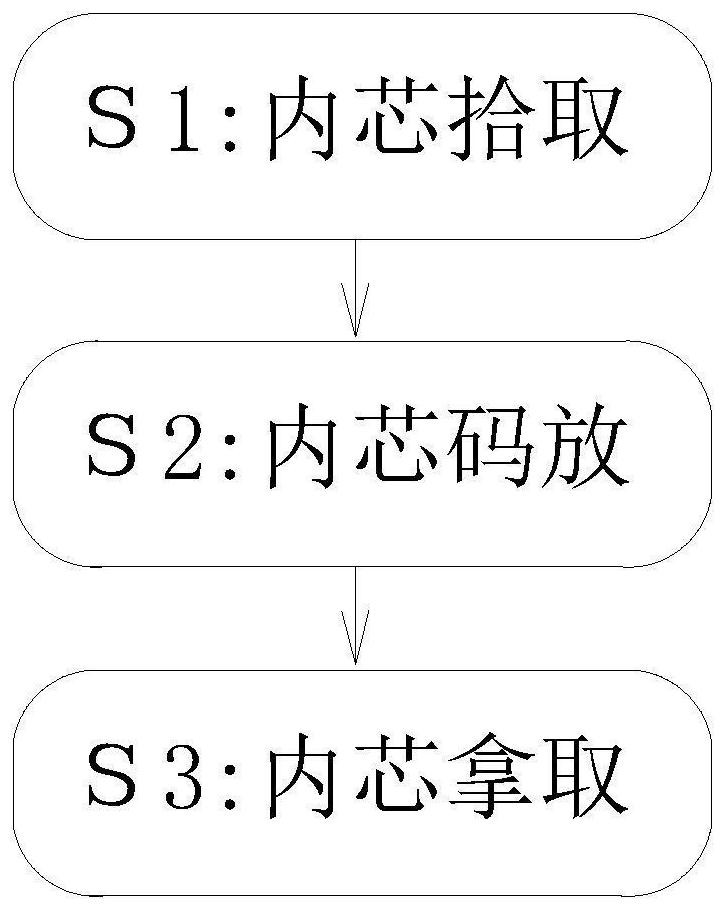

[0038] 1. A battery production line is used in the battery production line, which is applied to the battery production line, and transfers the inner core on the battery production line, which is convenient to take the core stacking method for easy access, including The following steps:

[0039] S1, the internal core picking: Pick the plurality of battery cores by the battery-producing battery in the battery production line, and transfer the picked inner core upwards;

[0040] S2, the inner core code: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com