Sludge biological landfill type dehydration treatment system

A treatment system and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of large landfill area and improve treatment efficiency , shorten the time required for degradation, and achieve the effect of long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

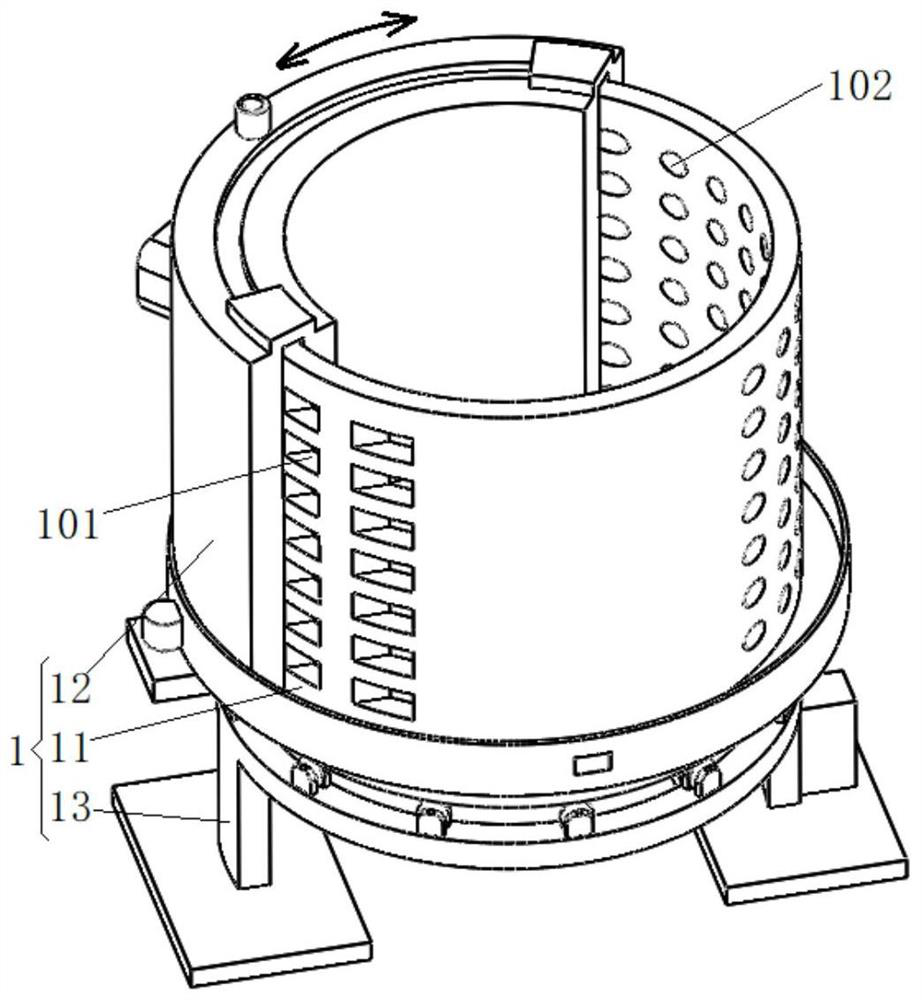

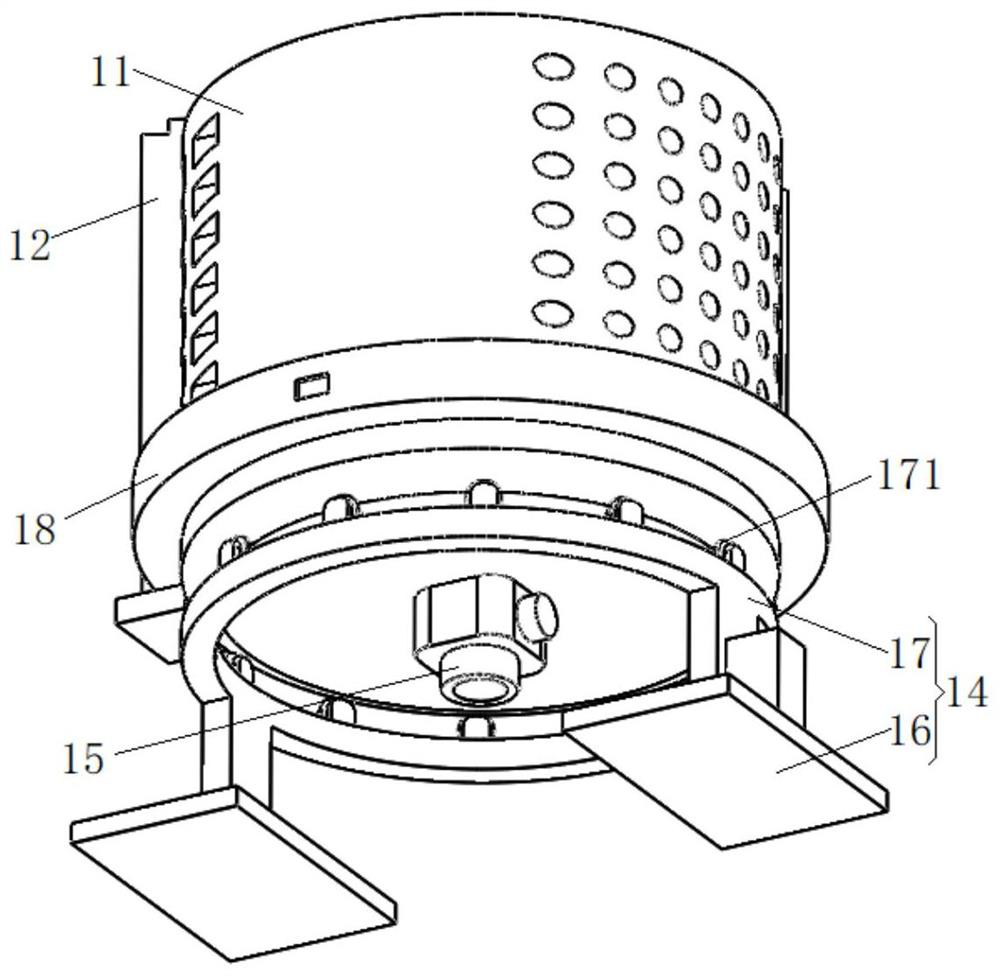

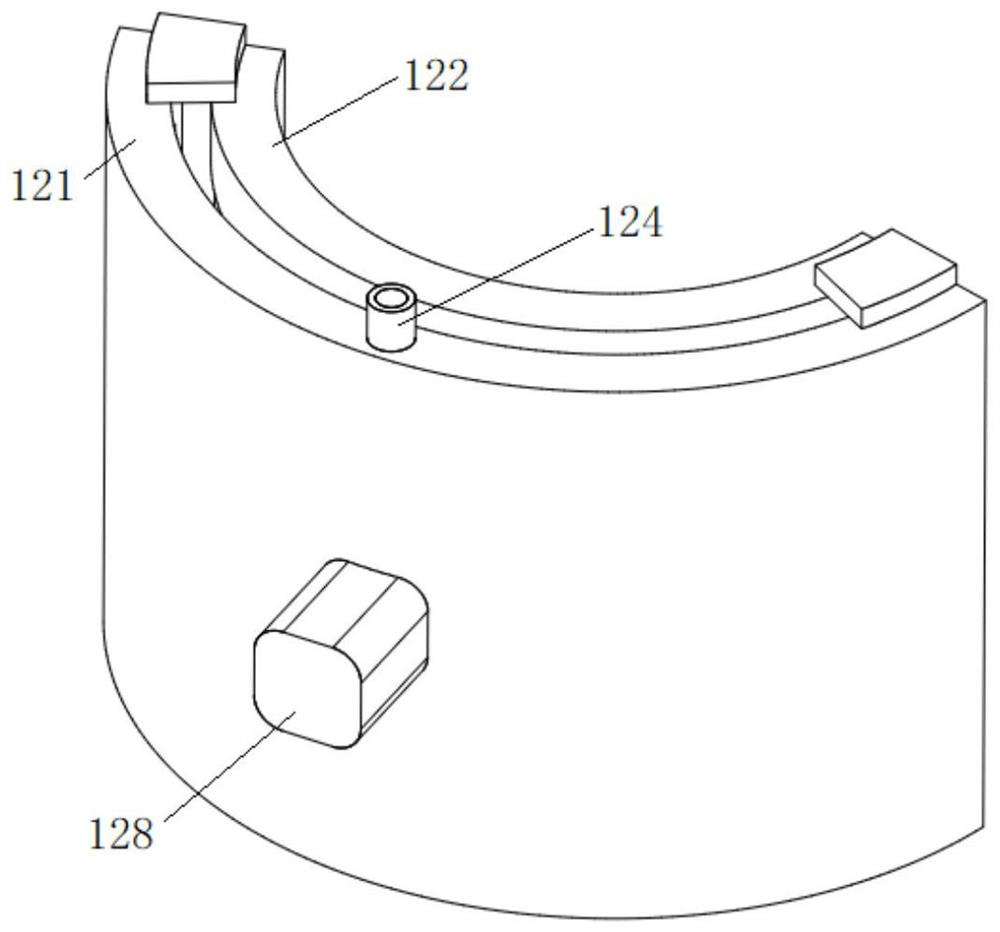

[0025] A sludge biological landfill dehydration treatment system, such as figure 1 and image 3 As shown, it includes a two-pole filter unit 1; the two-pole filter unit 1 includes a cylinder body 11 and a jacket 12; the cylinder body 11 is filled with sludge; the side walls on the opposite sides of the cylinder body 11 are respectively set There are a first filter hole 101 and a second filter hole 102; the aperture of the first filter hole 101 is larger than the aperture of the second filter hole 102; the jacket 12 slides circumferentially with the side wall of the cylinder 11 fit; the jacket 12 includes a first baffle 121 and a second baffle 122 connected to each other; the first baffle 121 is attached to the outer wall of the cylinder 11; the second baffle 122 is connected to the outer wall of the cylinder 11 The inner wall of the cylinder 11 is attached; the perip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com