Multi-stage linkage collecting device and method for ore leaching liquid in heap leaching field of metal mine

A collection device and multi-cascade technology, which is applied in the field of mine heap leaching field, can solve the problems of easy blockage of pipeline system, instability of heap leaching field, and low collection efficiency, so as to prevent pipeline blockage, improve stability and collection effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

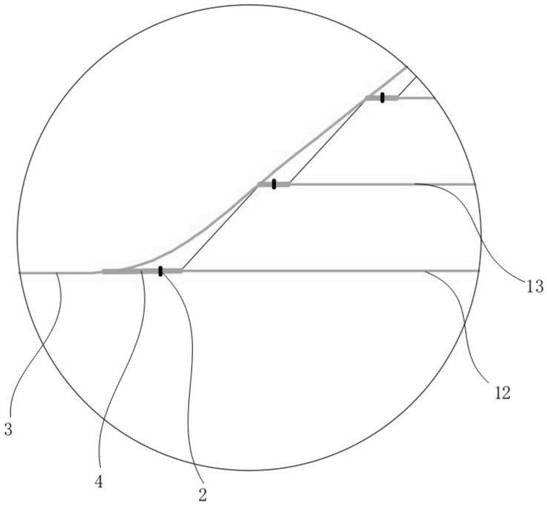

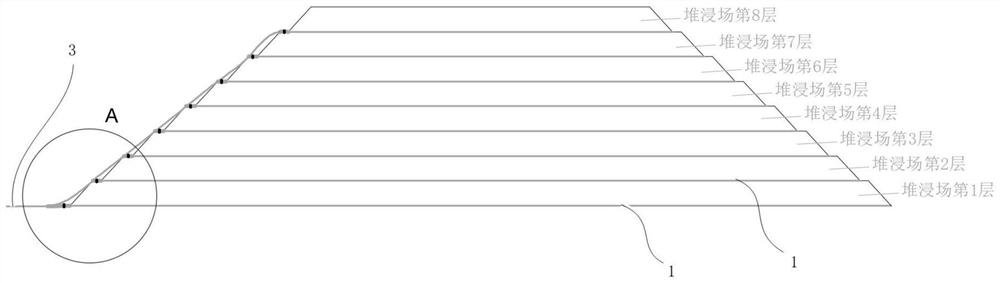

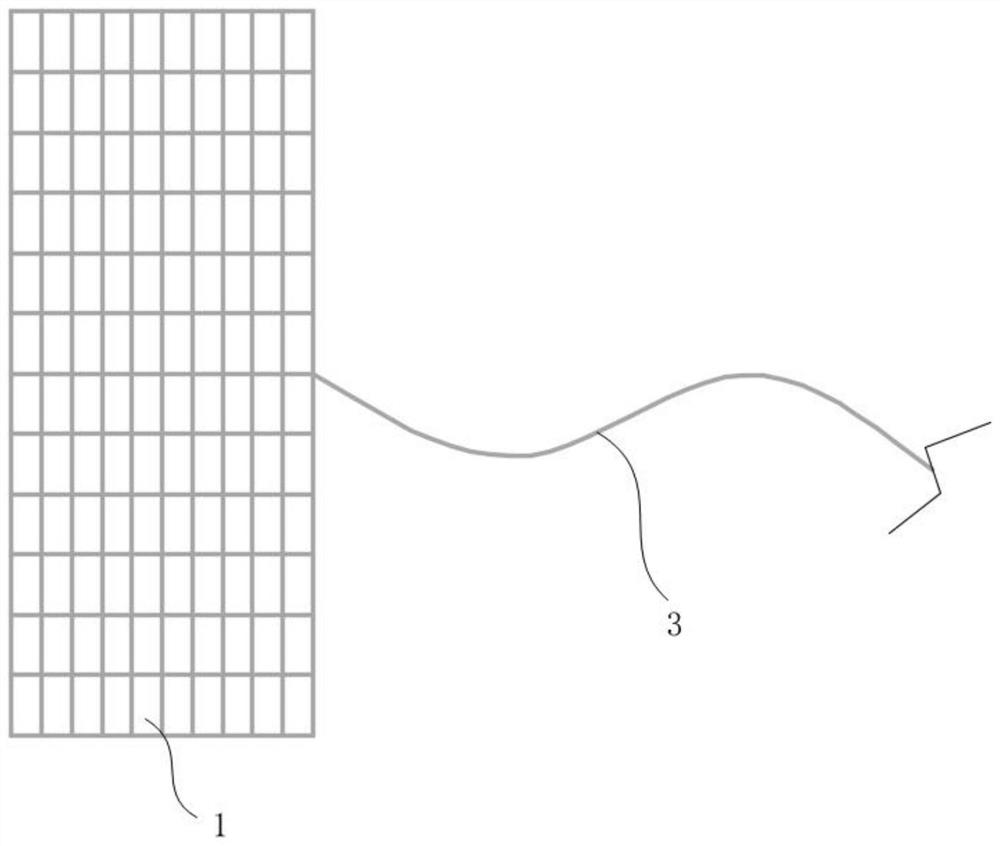

[0039] Such as Figures 1 to 3 As shown, a metal mine heap leaching site leaching solution multi-stage linkage collection device, including a number of leaching solution collection systems 1 respectively corresponding to the bottom ends of several layers of ore bulk material layers contained in the heap leaching site, one end corresponding to It is connected to several ore leaching liquid collection systems 1 and the other end is connected to the conveying system of the liquid sump, through several ore leaching liquid collection systems 1, respectively collect the ore leaching liquid that seeps down from between the ores in each layer of the heap leaching field, and The leaching liquid collected by each leaching liquid collection system 1 is uniformly transported to the liquid collection pool for processing through the conveying system, reducing the time and distance of seepage of the leaching liquid in the heap leaching field, and reducing the impact on the existing leaching l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com