Anti-adhesion and anti-fracture acetic acid silk yarn sizing equipment and process

An anti-blocking and acetic acid technology, applied in textiles and papermaking, liquid/gas/steam removal, textile material treatment, etc., can solve problems such as thread adhesion and breakage, achieve synchronous actions, reduce use costs, and improve uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

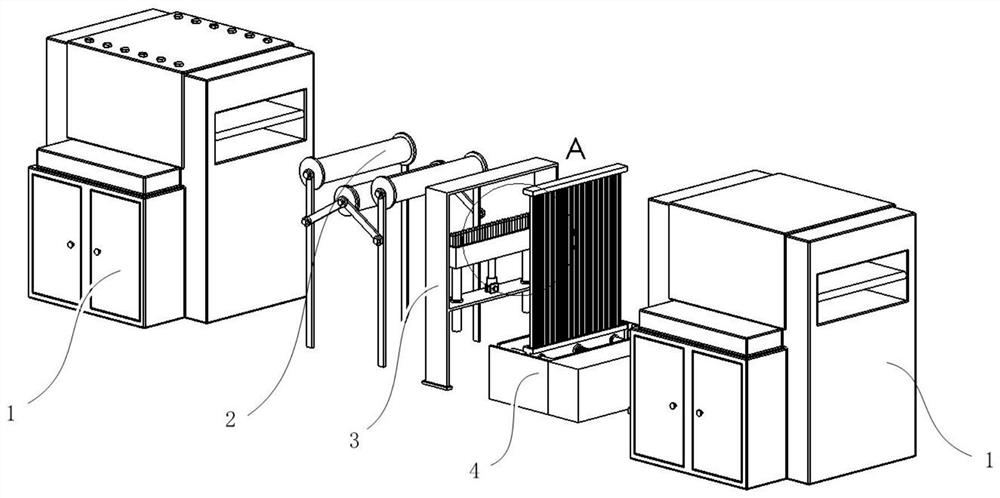

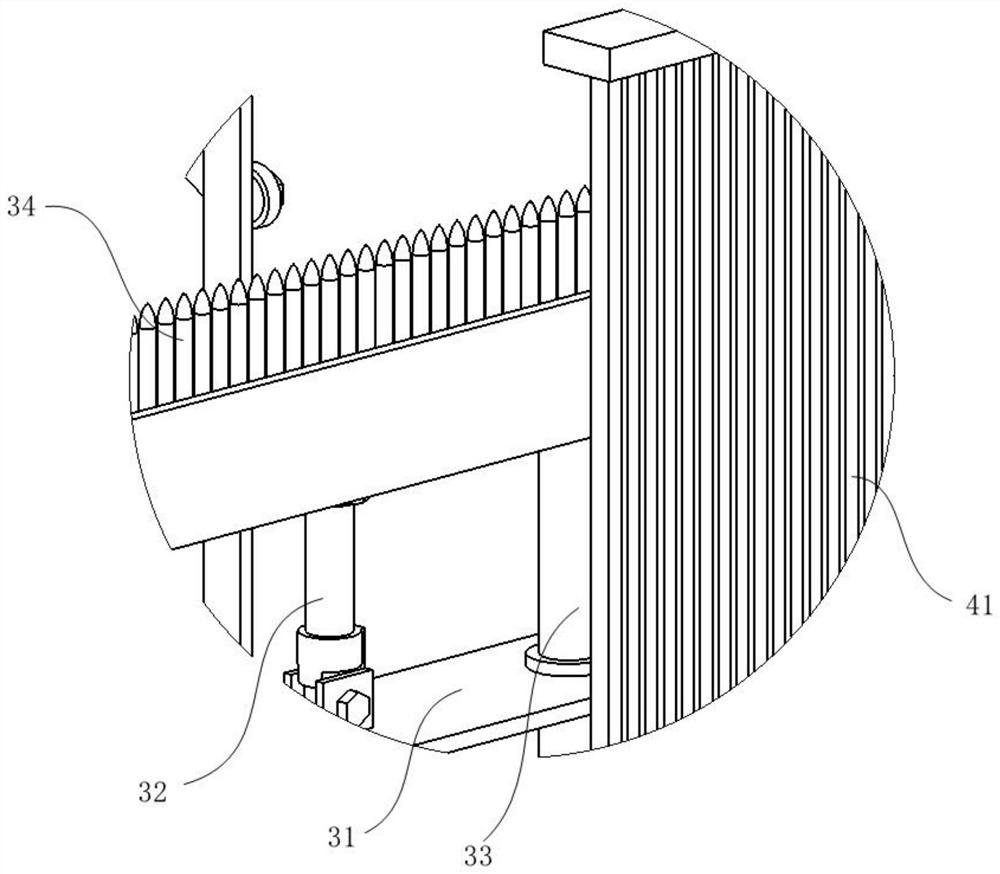

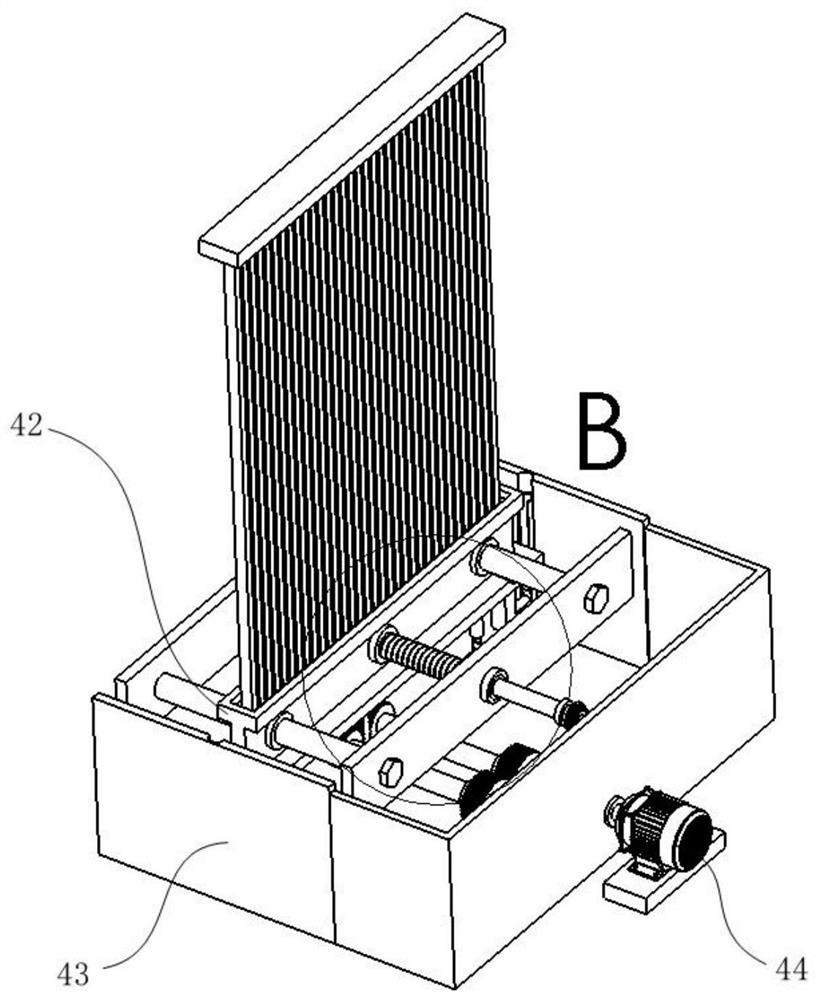

[0038] Such as figure 1As shown, an anti-adhesive inter-cracked acetate tank device includes an oven 1 for baking the wire after the upper slurry, and the oven 1 is sequentially provided with a tension of the yarn. Institution 2, separate the wire separated wire through the wire, the 筘 筘 筘 筘 筘 筘 筘,,, 筘, 筘 筘 筘 筘 筘 筘 筘 筘 筘 筘 筘 筘 筘 筘 筘 筘 筘 筘There is a driving assembly that drives the 筘 筘 41, the drive assembly includes a transverse mechanism that drives the pull-down 41 up and down movement of the lifting mechanism and the driven teeth 41, and through the up and down movement and the front and rear motion of the 筘 筘 机构 4 The teeth 41 act on the wire, keep the tension of the wire, increase its uniformity, so that the wire maintains a dispersed state after the treatment of the ostrich mechanism 4, prevents the adhesion to break, effectively solve the thread adhesion of the acetate slurry process.

[0039] In the present embodiment, the swing mechanism 4 further includes a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com