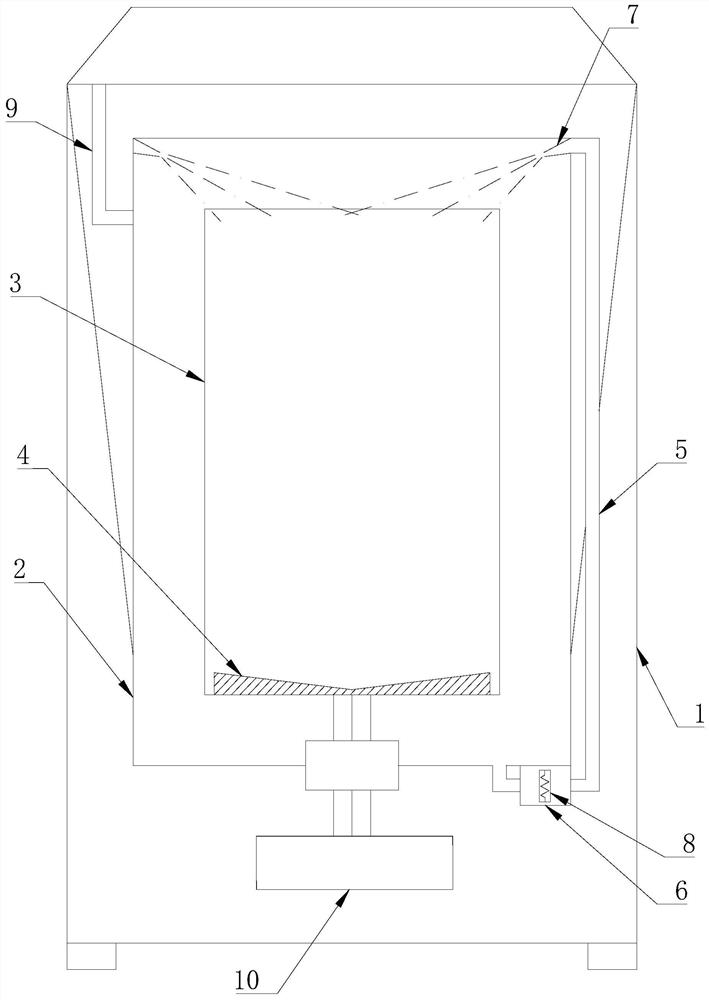

Heating circulating pump and washing machine

A heating cycle and heating module technology, which is applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of contact and winding between lint and heating parts, and achieve a suitable promotion and use, improve the degree of integration, and achieve remarkable results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

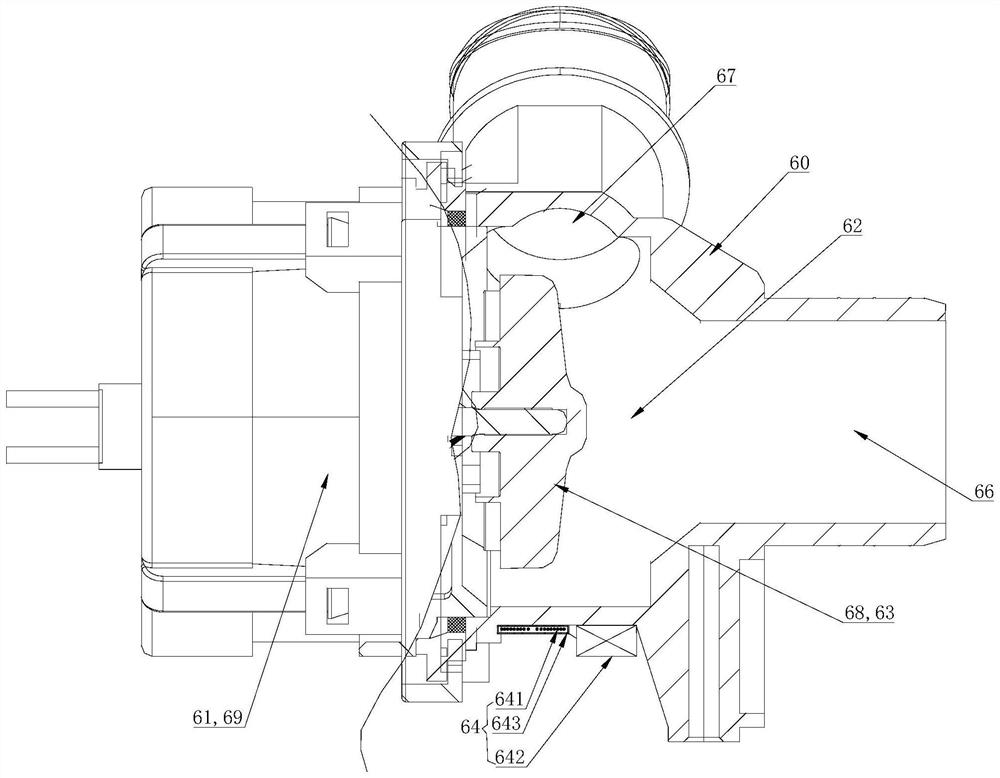

[0040] Such as figure 2As shown, a heating cycle pump is introduced in this embodiment, which includes a pump casing 60, and a pump cavity 62 for water flow is arranged inside the pump casing 60; a driving device 61 is installed on the pump casing 60 for driving the pump The water flow in the chamber 62 provides the flow driving force; the driving device 61 includes an impeller 68 disposed in the pump chamber, and the impeller 68 is made of metal, so that the impeller 68 directly constitutes the metal part 63 . The components of the impeller 68 contain materials such as iron, so as to be excited by eddy currents in the high-frequency alternating magnetic field generated by the electromagnetic heating module 64 to generate self-heating.

[0041] In this embodiment, the impeller 68 is entirely made of metal material, or partially made of metal material; preferably, at least a surface portion of the impeller 68 is made of metal material. Thereby, the impeller 68 of the driving ...

Embodiment 2

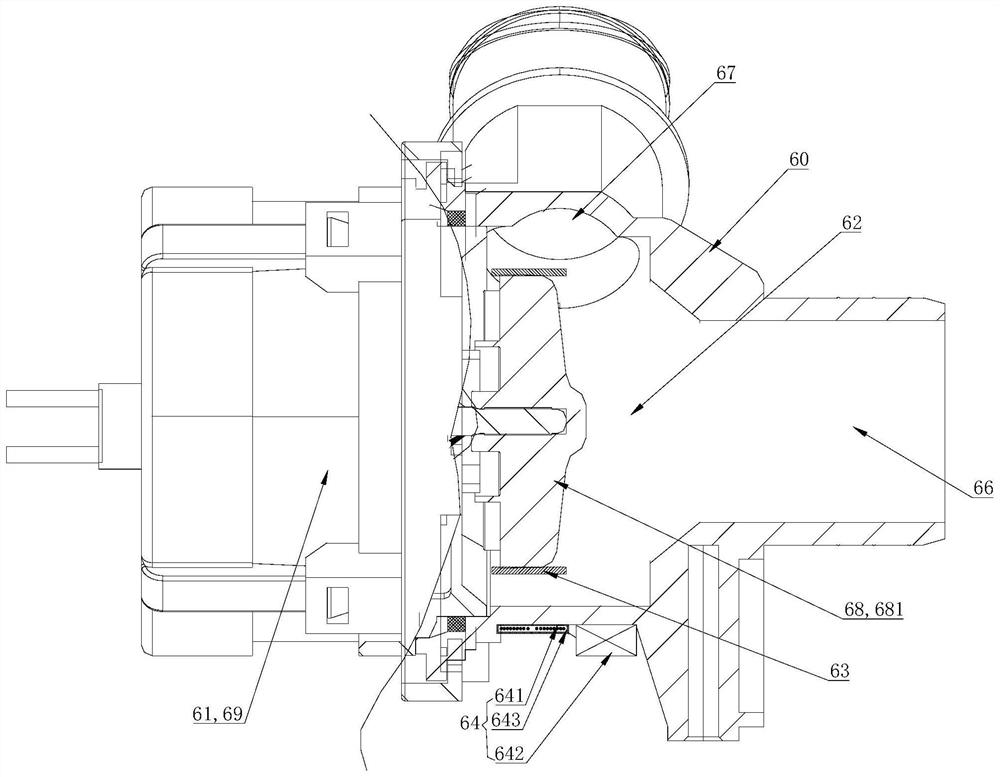

[0044] Such as image 3 As shown, a heating cycle pump is introduced in this embodiment, which includes a pump casing 60, and a pump cavity 62 for water flow is arranged inside the pump casing 60; a driving device 61 is installed on the pump casing 60 for driving the pump The water flow in the chamber 62 provides the flow driving force; the driving device 61 includes an impeller 68 arranged in the pump chamber 62 , and a metal part 63 is installed on the impeller 68 . The components of the metal piece 63 include materials such as iron, so as to be excited by eddy currents in the high-frequency alternating magnetic field generated by the electromagnetic heating module 64 to generate self-heating.

[0045] In this embodiment, the impeller 68 includes a plurality of blades 681 extending radially from the central rotating shaft, and each blade 681 is symmetrically arranged relative to the central rotating shaft. The impeller 68 is made of non-metallic material, and each blade 681...

Embodiment 3

[0054] Such as Figure 4 As shown, a heating cycle pump is introduced in this embodiment, which includes a pump casing 60, and a pump cavity 62 for water flow is arranged inside the pump casing 60; a driving device 61 is installed on the pump casing 60 for driving the pump The water flow in the cavity 62 provides the flow driving force; the inner wall of the pump cavity 62 is equipped with a metal piece 63 . The components of the metal piece 63 include materials such as iron, so as to be excited by eddy currents in the high-frequency alternating magnetic field generated by the electromagnetic heating module 64 to generate self-heating.

[0055] In this embodiment, the metal piece 63 is fixedly installed on the inner wall of the pump chamber 62, and the metal piece 63 is in the high-frequency magnetic field generated by the electromagnetic heating module 64. The contacted flowing water conducts heat exchange and heats the water to achieve the effect of heating the water flowin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com