Giant-span underground cave depot reserved double-rock-pillar support eight-part excavation construction method

A construction method and cavern technology, applied in underground chambers, earthwork drilling, wellbore lining, etc., can solve the problems of no technical standard construction technology, no successful case projects, and high economic costs, so as to achieve spacious construction space and ensure surrounding rock stability and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

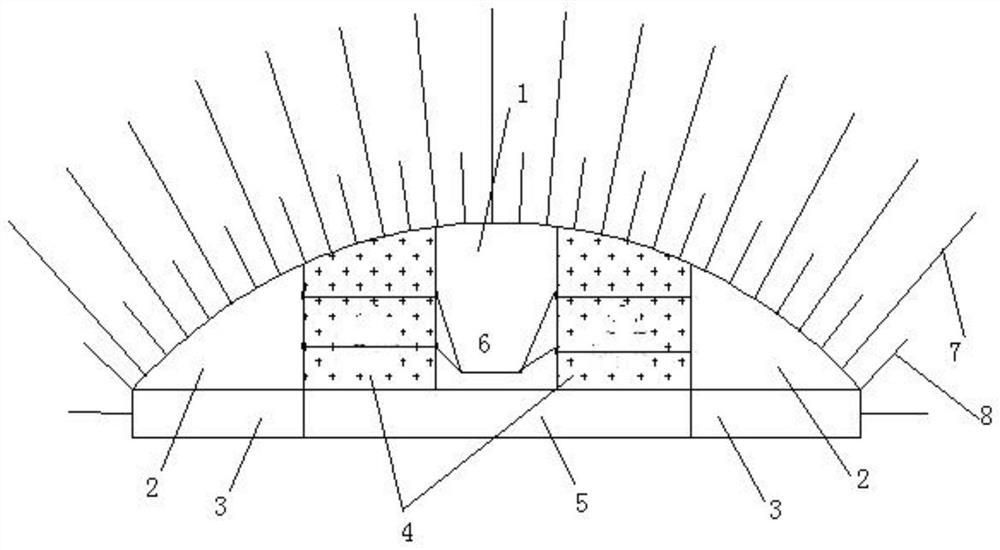

[0028] The present invention is an excavation construction method for eight sections supported by double rock pillars reserved for giant-span underground caverns, which is suitable for giant-span underground cavern projects with hard surrounding rock formations spanning more than 70m but less than 75m, and the surrounding rock level belongs to Class II Or level III, that is, [BQ] between 400 and 550; applicable cavern section form: straight wall arched flat razor-shaped section without inversion, side wall height not exceeding 10m, and sagittal height not exceeding 10m; the groundwater level is required to be Below the cavern floor.

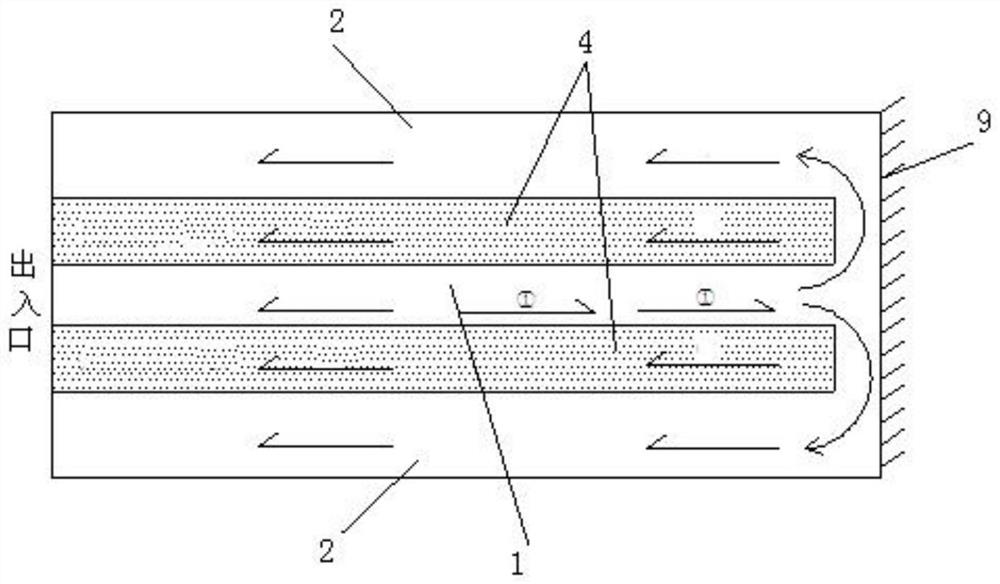

[0029] During construction, the excavation surface of the cavern shall be partitioned first, such as figure 1 with figure 2 As shown in , the excavation surface of the cavern is divided vertically into two separate upper and lower parts, the part above the arch line is the upper part construction area, and the part below is the lower part const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com