A turbine blade with bolt-on ceramic armor

A turbine blade, fixed technology, applied in the direction of blade support components, machines/engines, mechanical equipment, etc., can solve the problems of low cooling effect and large cooling air consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

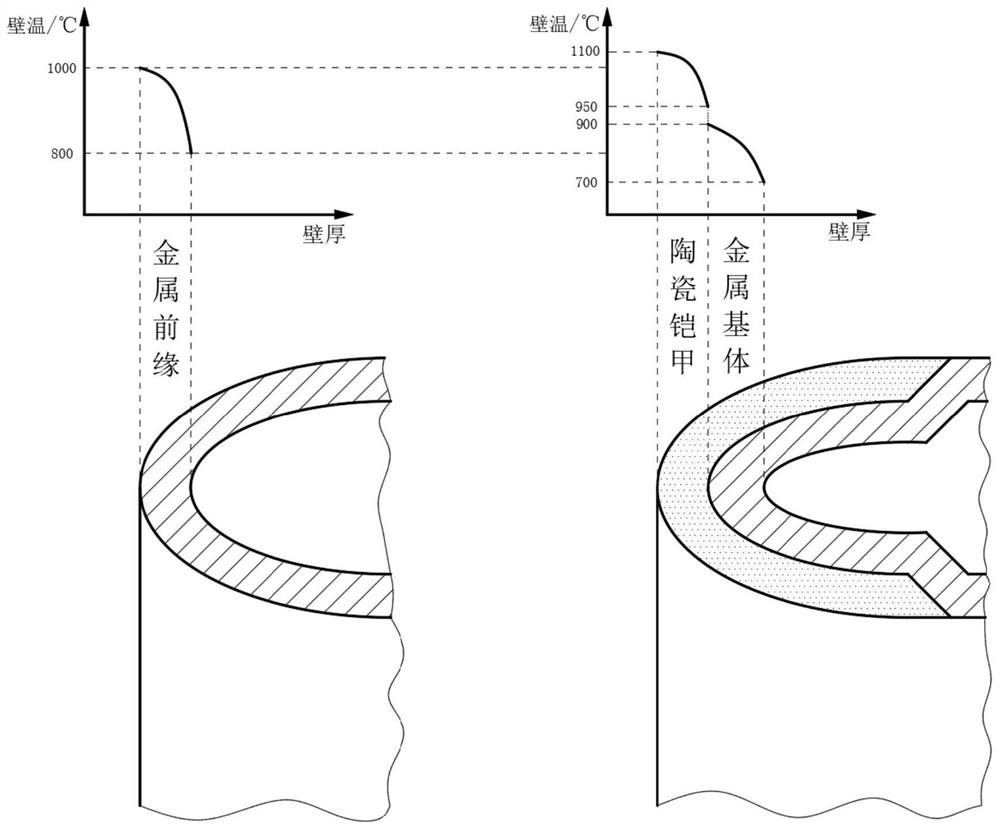

Problems solved by technology

Method used

Image

Examples

Embodiment 1

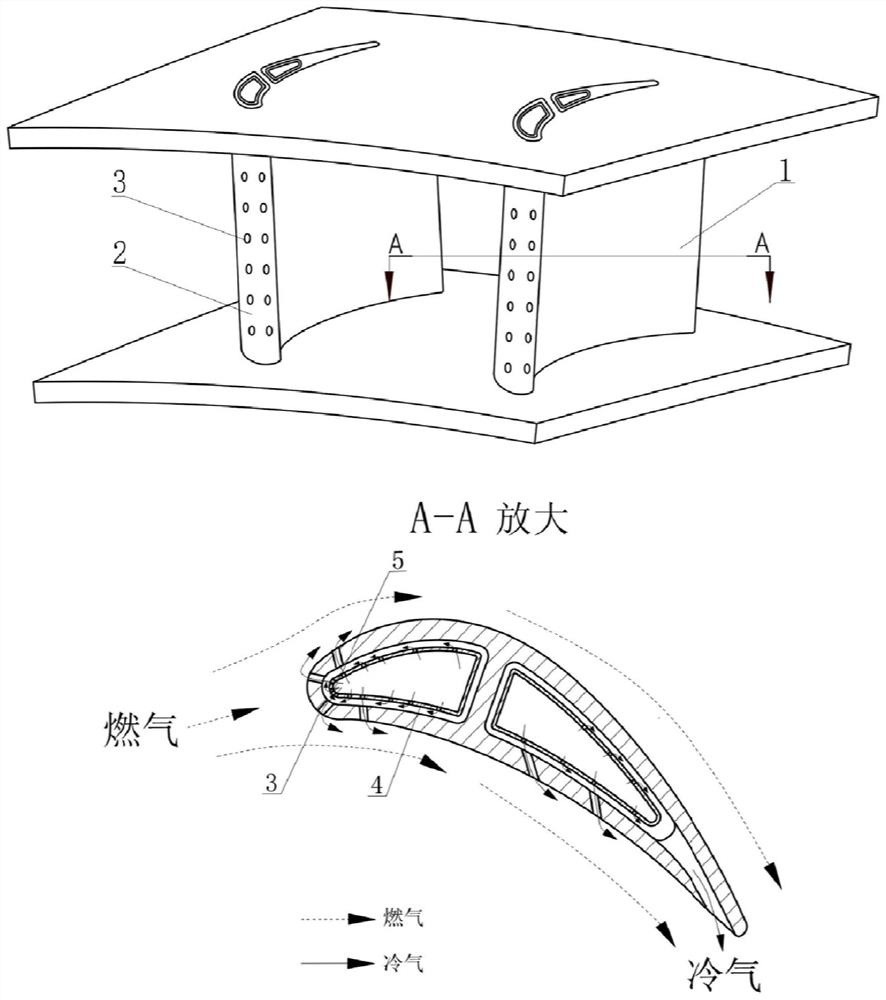

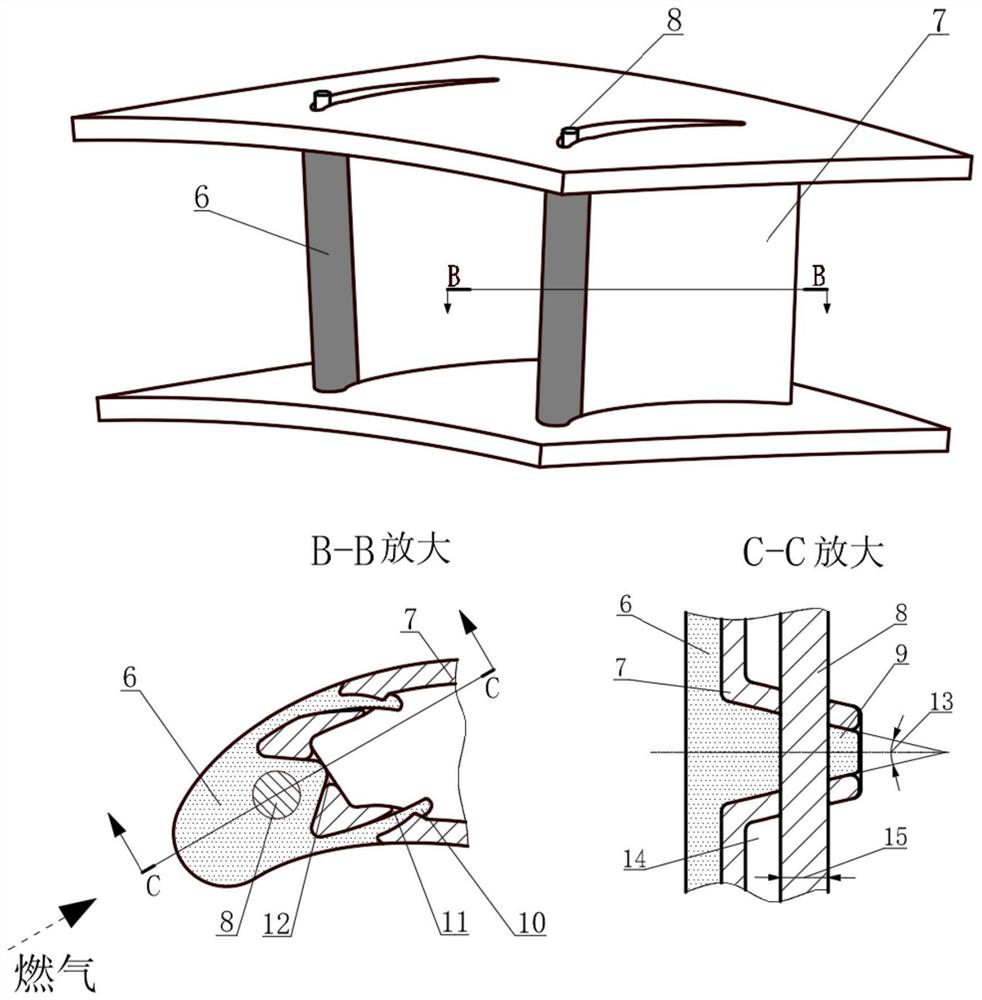

[0022] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

[0023] see figure 2 As shown, this embodiment is a turbine blade using a bolt-fixed ceramic armor, which is composed of a leading edge 6 of a ceramic matrix composite material, a metal matrix 7, and a fixed bolt 8. The leading edge 6 of ceramic matrix composite material is made of ceramic matrix composite material, and the metal matrix 7 and the fixing pin 8 are both made of superalloy. During use, insert the pin hole on the ceramic armor and the metal substrate 7 simultaneously, make the two be connected and fixed. In order to install smoothly and ensure the structure is firm enough, the fixed pin diameter φD 1 Be 1.6mm, the orientation of the ceramic armor pinhole boss 9 is parallel to the gas direction. Pin hole boss wedge angle ∠θ 1 = 16°....

Embodiment 2

[0025] Such as Figure 4 As shown, this embodiment is a turbine blade that adopts a fixed ceramic armor with offset pins. In this embodiment, the position of the fixed pin 8 is offset. Among them, 6 parts of the front edge of the ceramic matrix composite material are provided with semi-square pin holes, while 7 parts of the metal matrix are provided with complete square pin holes. The offset square fixed bolt 16 is the main stress-bearing part. In order to ensure reliability, 17. The side length of the offset square fixed pin is L=1.2mm, and the angle of the boss of the ceramic armor pin hole is parallel to the gas direction. Pin hole boss wedge angle side length ∠θ 1 = 12°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com