Harmonic reducer static stiffness and hysteretic curve precision test device and test method

A technology of harmonic reducer and hysteresis curve, which is applied in the field of precision testing devices for static stiffness and hysteresis curve of harmonic reducer, and can solve problems such as tediousness, stiffness or hysteresis curve error, and data dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

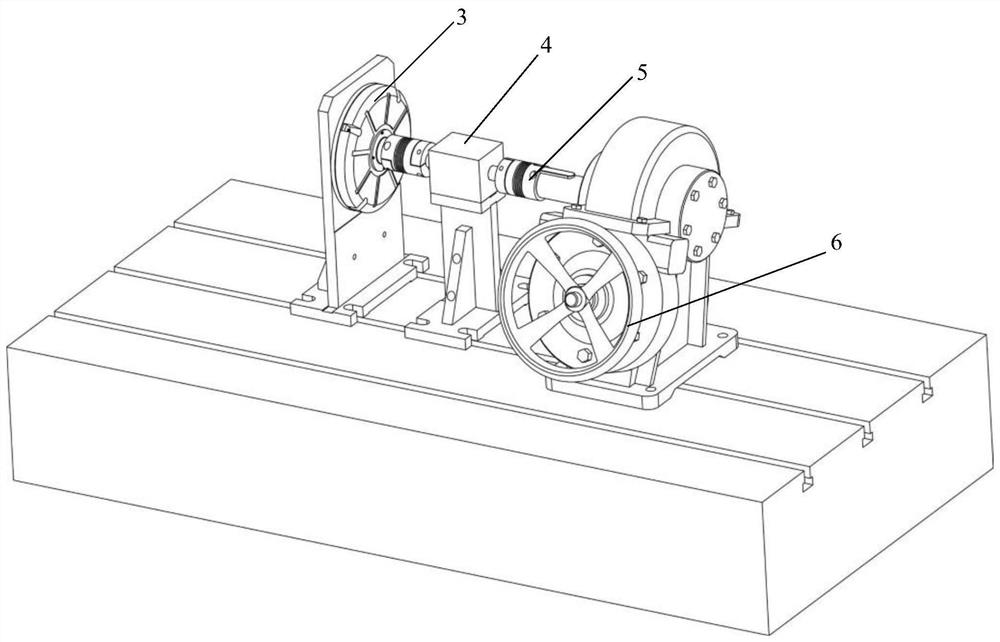

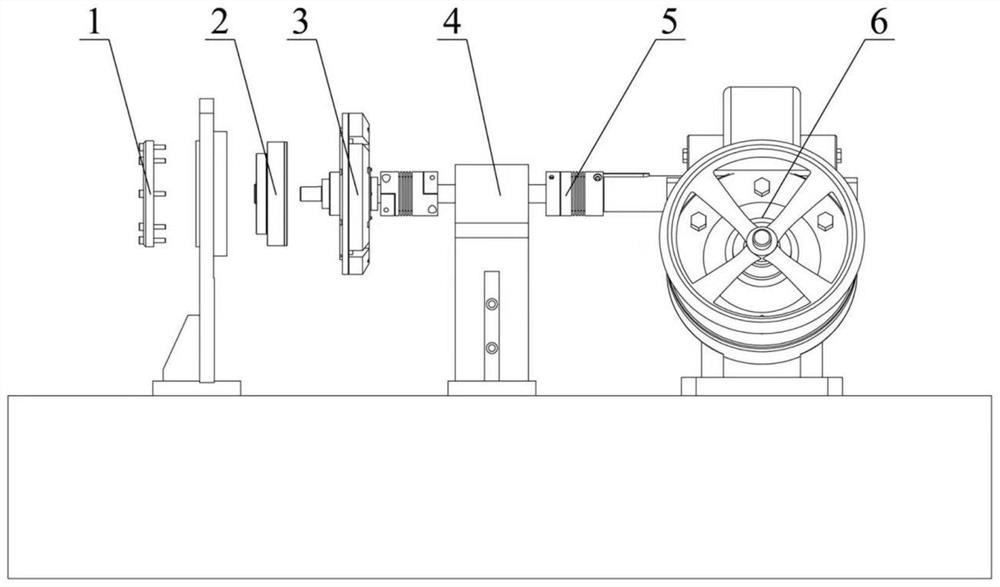

[0032] see figure 1 and figure 2 , this embodiment provides a precision test device for static stiffness and hysteresis curve of a harmonic reducer, including:

[0033] The worm gear loading mechanism 6, the torque sensor 4, the angle encoder 3 and the fixing mechanism for fixing the harmonic reducer 2, the worm gear loading mechanism 6, the torque sensor 4, the angle encoder 3 and the harmonic reducer 2 are connected in sequence The worm gear loading mechanism 6 is used to gently apply torque to the harmonic reducer 2; the torque sensor 4 is used to collect the torque applied by the worm gear loading mechanism 6 in real time; the angle encoder 3 is used to collect the harmonic reducer 2 in real time Output rotation angle under force.

[0034] The harmonic reducer static stiffness and hysteresis curve precision testing device provided by the present invention includes a worm gear loading mechanism 6, a torque sensor 4, an angle encoder 3 and a fixing mechanism, wherein the ...

Embodiment 2

[0044] This embodiment provides a precise test method for static stiffness and hysteresis curve of a harmonic reducer, including:

[0045] Using the harmonic reducer static stiffness and hysteresis curve precision testing device to test the harmonic reducer, correspondingly obtain multiple sets of test data, each set of test data includes input torque and output rotation angle;

[0046] A static stiffness and hysteresis curve is constructed based on the test data, and the static stiffness and hysteresis curve are used to characterize the variable relationship between the input torque and the output rotation angle.

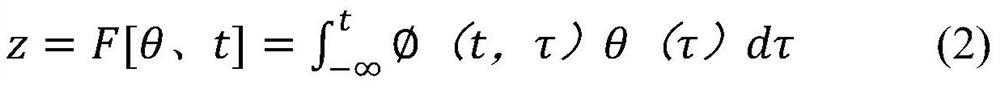

[0047] For the rigid-flexible compound transmission system, the input torque h and the output rotation angle θ are usually described by a nonlinear equation h=k(θ) in the prior art, where h is used to represent the static stiffness and hysteresis of the harmonic reducer The function of the back curve, the experiment shows that the output rotation angle θ is not onl...

Embodiment 3

[0087] This embodiment provides a computer-readable storage medium, on which a computer program is stored, and when the computer program is run by a processor, the steps of the above-mentioned precision testing method for static stiffness and hysteresis curve of a harmonic reducer are executed.

[0088] Compared with the prior art, the beneficial effect of the computer-readable storage medium provided by this embodiment is the same as that of the harmonic reducer static stiffness and hysteresis curve precision testing method provided by the above technical solution, and will not be repeated here.

[0089]Those of ordinary skill in the art can understand that all or part of the steps in the above inventive method can be completed by instructing related hardware through a program. The above program can be stored in a computer-readable storage medium. When the program is executed, it includes: For each step of the method in the above embodiments, the storage medium may be: ROM / RAM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com