Continuous production system and method of acetic acid and butyl ester mixture

A technology of mixed butyl acetate and esterification tower, which is applied in the separation/purification of carboxylic acid esters, preparation of carboxylic acid esters, chemical instruments and methods, etc., which can solve the problem of increasing the speed of olefins, affecting the rectification process, and reducing the acetic acid mixed butyl ester Problems such as ester yield, to achieve the effect of reducing material consumption and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

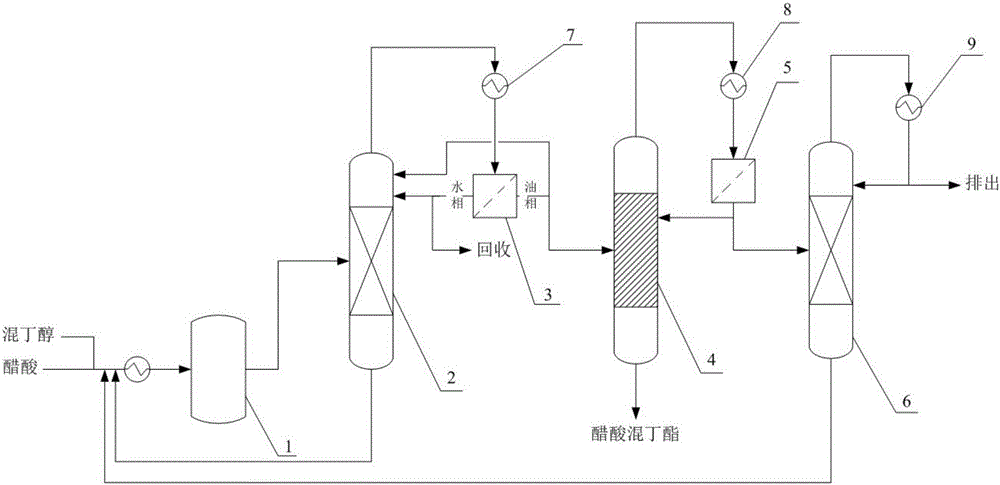

[0058] Such as figure 1 Shown, present embodiment provides a kind of continuous production system of mixed butyl acetate, described system comprises esterification reactor 1, esterification tower 2, the first phase separator 3, rectification tower 4, the second phase separation Device 5 and light removal tower 6; Wherein, the discharge port of esterification reactor 1 links to each other with the feed port of esterification tower 2, the tower top material outlet of esterification tower 2 is connected with the feed port of first phase separator 3 connected, the bottom material outlet of the esterification tower 2 is connected with the feed port of the esterification reactor 1, the water phase outlet of the first phase separator 3 is connected with the top return inlet of the esterification tower 2, and the first phase separator The oil phase outlet of 3 is connected with the feed inlet of the tower top return inlet of esterification tower 2 and rectification tower 4 simultaneou...

Embodiment 2

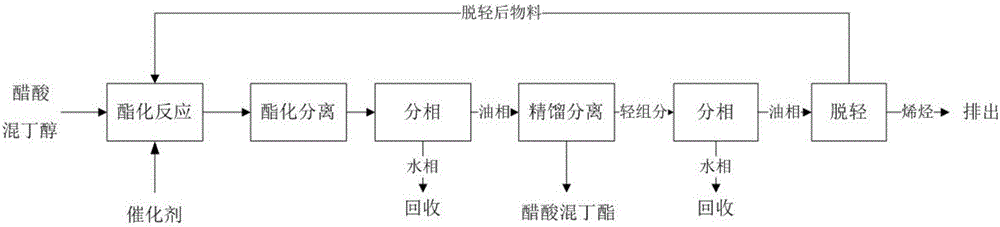

[0061] Such as figure 2 Shown, present embodiment provides a kind of method that adopts system described in embodiment 1 to carry out the continuous production of mixed butyl acetate, described method may further comprise the steps:

[0062] (1) After raw material acetic acid and mixed butanol are mixed in esterification reactor 1, acidic catalyst sulfuric acid is added to carry out esterification;

[0063] (2) step (1) esterification reaction gained material enters esterification tower 2 and carries out preliminary separation, and esterification tower gained tower top material obtains water phase and oil phase after the first cooling device 7 condensation and the first phase separator 3, A part of the water phase is refluxed to the esterification tower 2, and another part of the water phase is recovered. After the oil phase is rectified and separated through the rectifying tower 4, mixed butyl acetate is obtained at the bottom of the rectifying tower 4, and the oil phase fra...

Embodiment 3

[0067] This embodiment provides a method for the continuous production of mixed butyl acetate using the system described in Example 1, except that the temperature at the top of the esterification tower 2 is 93°C, the temperature at the bottom of the tower is 115°C, and the oil The reflux ratio of the phase material is 0.8, and the reflux ratio of the water phase material is 4; the tower top temperature of the rectifying tower 4 is 95°C, the tower bottom temperature is 125°C, and the tower top reflux ratio is 4; the tower top temperature of the light removal tower 6 is 65 DEG C, the tower kettle temperature is 125 DEG C, and the reflux ratio is 18, other material consumption and operating process are all identical with embodiment 2;

[0068] Wherein, the content of mixed butyl acetate in the oil phase fraction at the top of the rectifying tower is 70wt%, the content of mixed butanol is 15wt%, and the content of olefin impurities is 15wt%; The content of butyl ester is 80 wt%, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com