A continuous and stable discharge device and method for heavy products of a coarse coal slime separator

A sorting machine and coarse coal slime technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of heavy product moisture, increased water consumption, and difficult system control, etc., and achieve stable properties of heavy products , continuous and stable discharge, and the effect of simplifying the subsequent process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

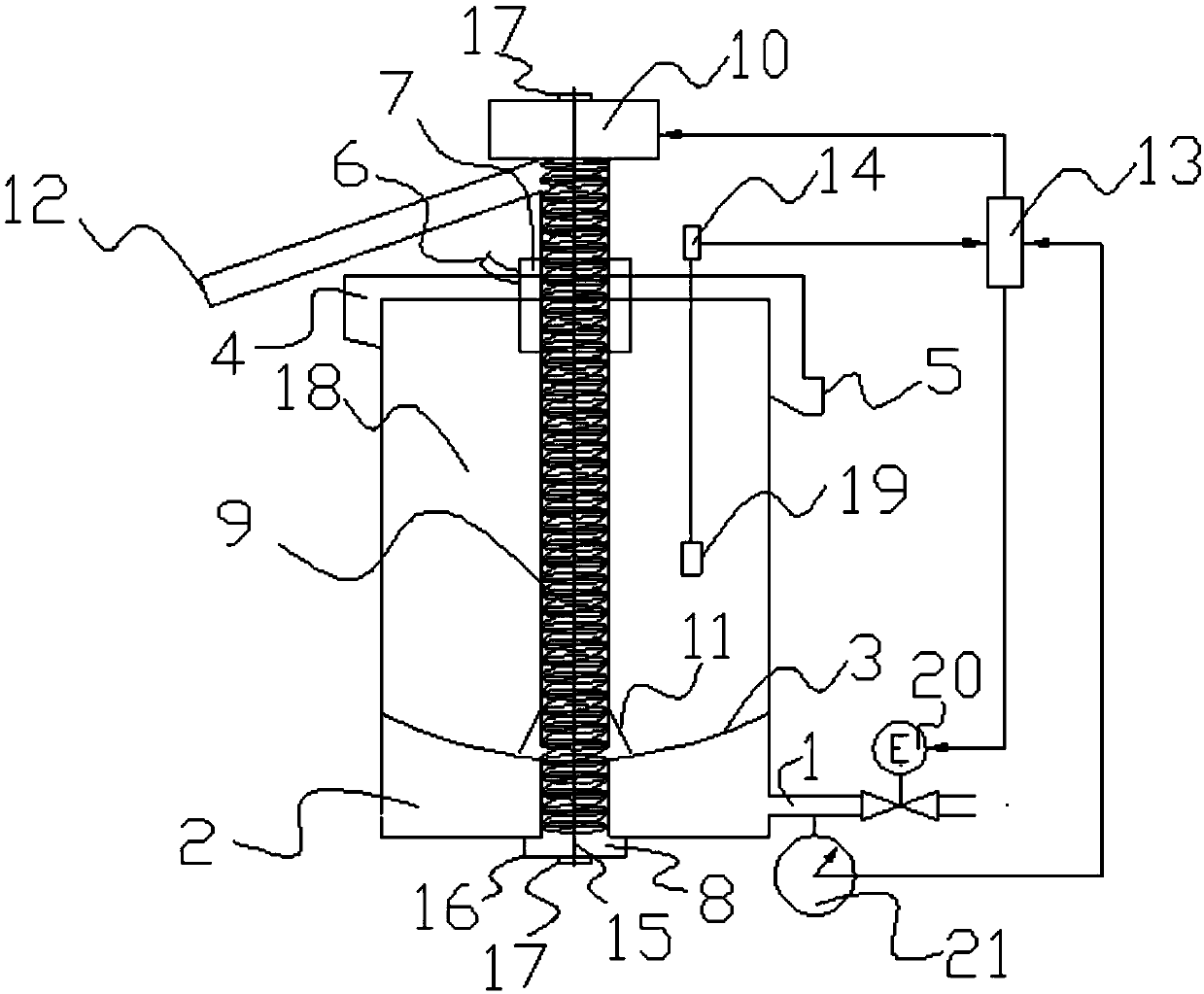

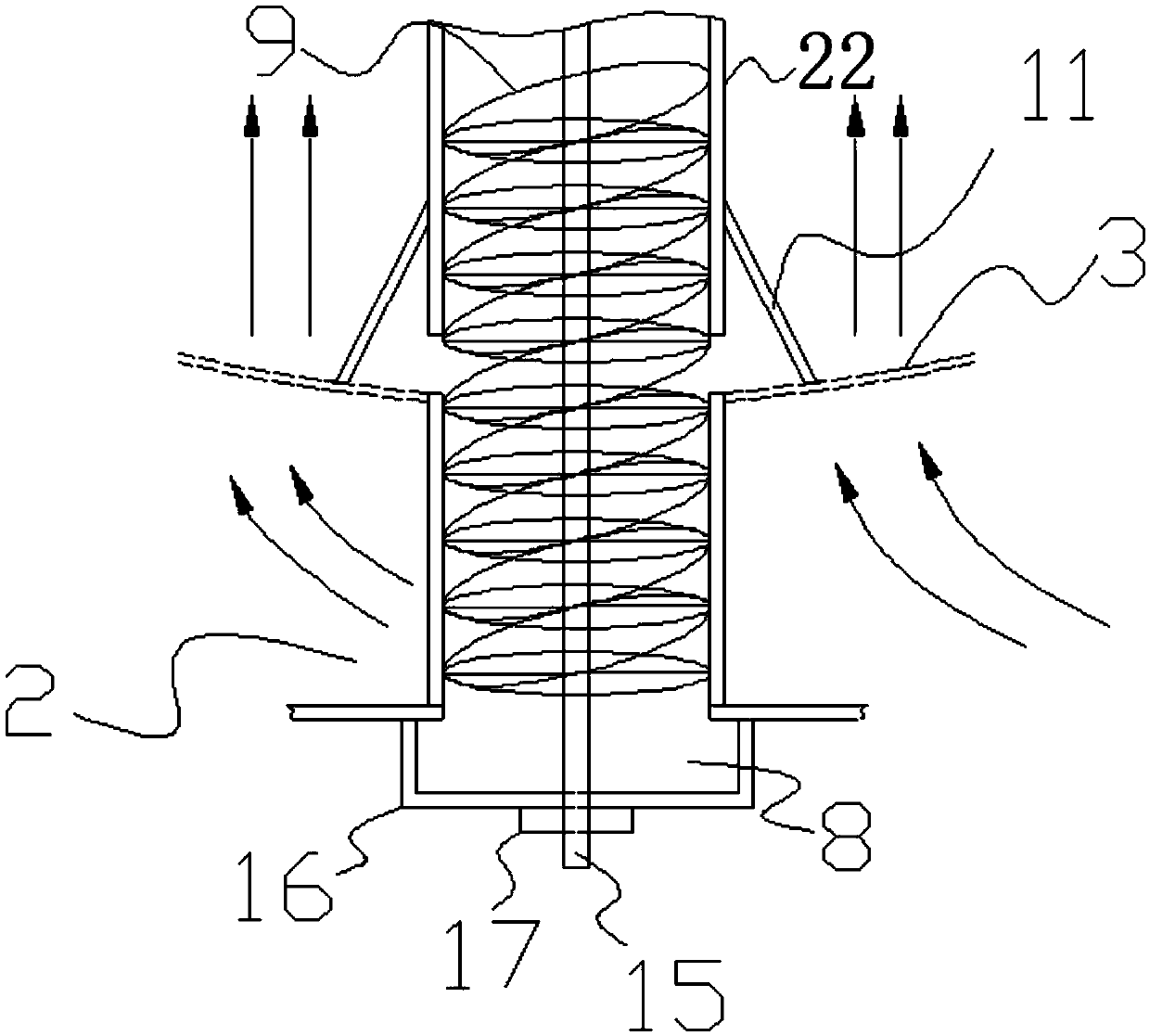

[0027] Such as figure 1 Shown is a continuous and stable discharge device for heavy products of a coarse coal slime separator, including a separator main body 18, a water supply system, a feeding system, a light product overflow system, a heavy product discharge system and an automatic control system, wherein :

[0028] The water supply system includes a water tank 2 arranged at the bottom of the main body 18 of the sorting machine. A water inlet 1 is arranged on one side of the water tank 2. A control valve 20 and a water inlet pressure gauge 21 are arranged at the water inlet 1. A water flow distributor 3 is arranged on the upper part of the water tank 2. The water flow distributor 3 is provided with several holes;

[0029] The feeding system is arranged at the center of the top of the main body 18 of the sorting machine, including a feeding pipe 6 and a feeding buffer cylinder 7, and the feeding pipe 6 is connected to one side of the feeding buffer cylinder 7;

[0030] Th...

Embodiment 2

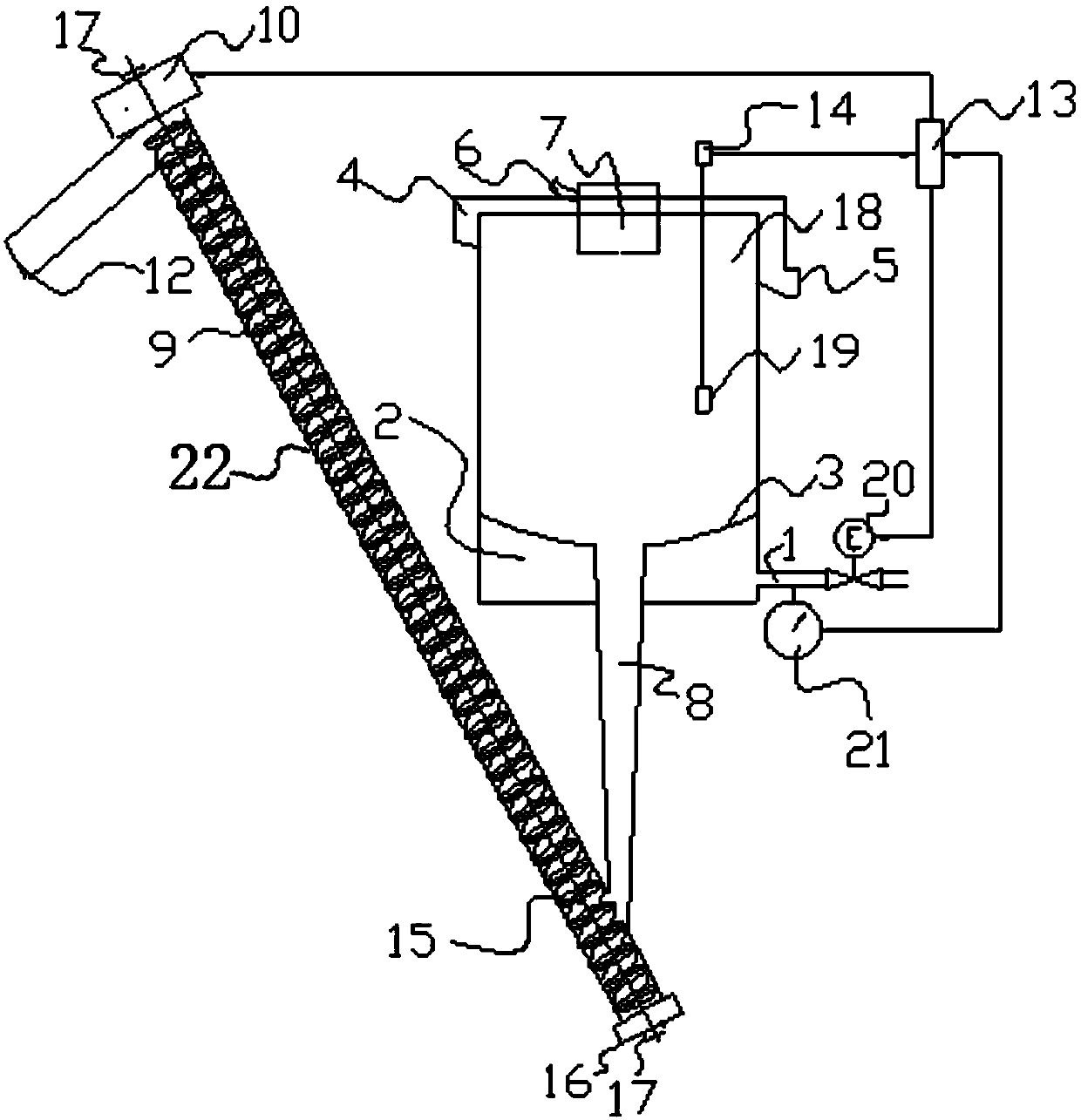

[0038] Such as image 3 Shown is another embodiment of the present invention, a side screw lifting heavy product continuous and stable discharge device. The specific implementation is that the main body 18 of the sorter, the water supply system, the feeding system, the light product overflow system and the automatic control system are all consistent with the central spiral lifting heavy product continuous and stable discharge device of embodiment 1, the difference is that the heavy product discharge system. In this embodiment, the spiral lifting device is located outside the main body 18 of the sorter, and is installed obliquely; the heavy product collection tank 8 extends from the bottom of the water tank 2 and is connected to the bottom of the spiral lifting device.

[0039] This embodiment adopts the method of lifting the heavy product with a side screw, the material with higher density settles down, and finally enters the heavy product collection tank 8, and the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com